Polyurethane rigid foam material for external thermal insulation system of external wall

A polyurethane rigid foam and external wall thermal insulation technology, which is applied in thermal insulation, walls, climate change adaptation, etc., can solve the problems of high cost, swelling, falling off, etc., achieve smooth surface, strong adhesion, and relieve wall cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

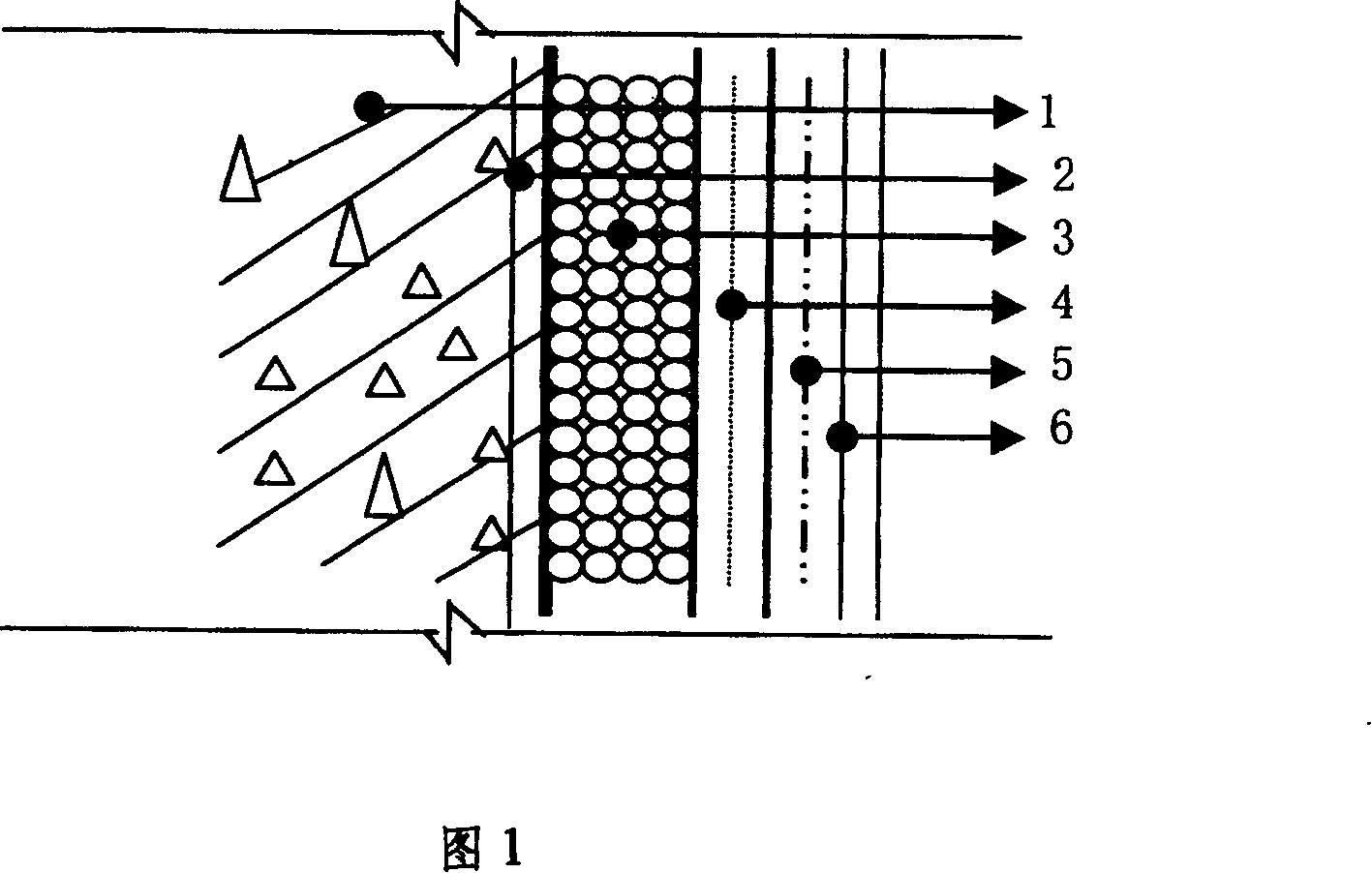

[0041] The invention relates to a rigid polyurethane foam for construction that can be directly sprayed on the wall and its matching external wall insulation material system, in particular to spray-coated modified asphalt polyurethane rigid foam, creosote polyurethane rigid foam and Rosin polyester polyurethane rigid foam and its preparation method, polyurethane moisture-proof primer and its preparation method matched with the rigid foam, vinyl acetate-ethylene copolymer emulsion interface agent and crack-resistant polymer dry prepared by redispersible latex powder Mortar-mixed plastering layer and preparation method thereof.

[0042] The present invention is realized by following technical scheme:

[0043] (1) Prepare spray-type polyurethane rigid foam combination polyether polyol;

[0044] (2) Carry out chemical foaming with prepared combination polyether polyol and polyisocyanate to prepare spray polyurethane rigid foam;

[0045] (3) Synthetic polyurethane moisture-proof ...

Embodiment 1

[0057] Embodiment 1. modified coal tar pitch polyurethane rigid foam

[0058] serial number

Name

parts by mass

1

40-60

2

Ethylenediamine polyether polyol

60-40

3

60-80

4

Silicone Foam Stabilizer CGY-1

4-6

5

Triethanolamine crosslinking agent

20-30

6

Castor Oil Crosslinker

10-20

7

2,4,6-tris(dimethylaminomethyl)phenol

10-15

8

Potassium acetate

1.5-3.0

9

0.5-1.0

10

22-30

11

DMMP

8-15

12

water

1-2

13

Fluorodichloroethane

40-60

14

Polyisocyanate curing agent (isocyanate index)

1.05-1.10

[0059] Typical Foam Properties:

[0060] Free foam density: 32kg / m 3 ; Water absorption (V / V) 1.2%; Compres...

Embodiment 2

[0061] Embodiment 2. rosin polyester polyurethane rigid foam

[0062] serial number

name

parts by mass

1

Sucrose polyether polyol

40-60

2

Ethylenediamine polyether polyol

60-40

3

80-100

4

Silicone Foam Stabilizer AK8801

4-6

5

Triethanolamine crosslinking agent

30-50

6

2,4,6-tris(dimethylaminomethyl)phenol

6-8

7

Triethylenediamine

4-7

8

Potassium acetate

1.5-3.0

9

0.5-1.0

10

22-30

11

DMMP

8-15

12

water

1-2

13

Fluorodichloroethane

40-60

14

Polyisocyanate curing agent (isocyanate refers to

number)

1.05-1.10

[0063] Typical Foam Properties:

[0064] Free foam density: 30.6kg / m 3 ; Compressive strength: 164kpa; Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com