Method for producing hyaluronic acid and its special strain

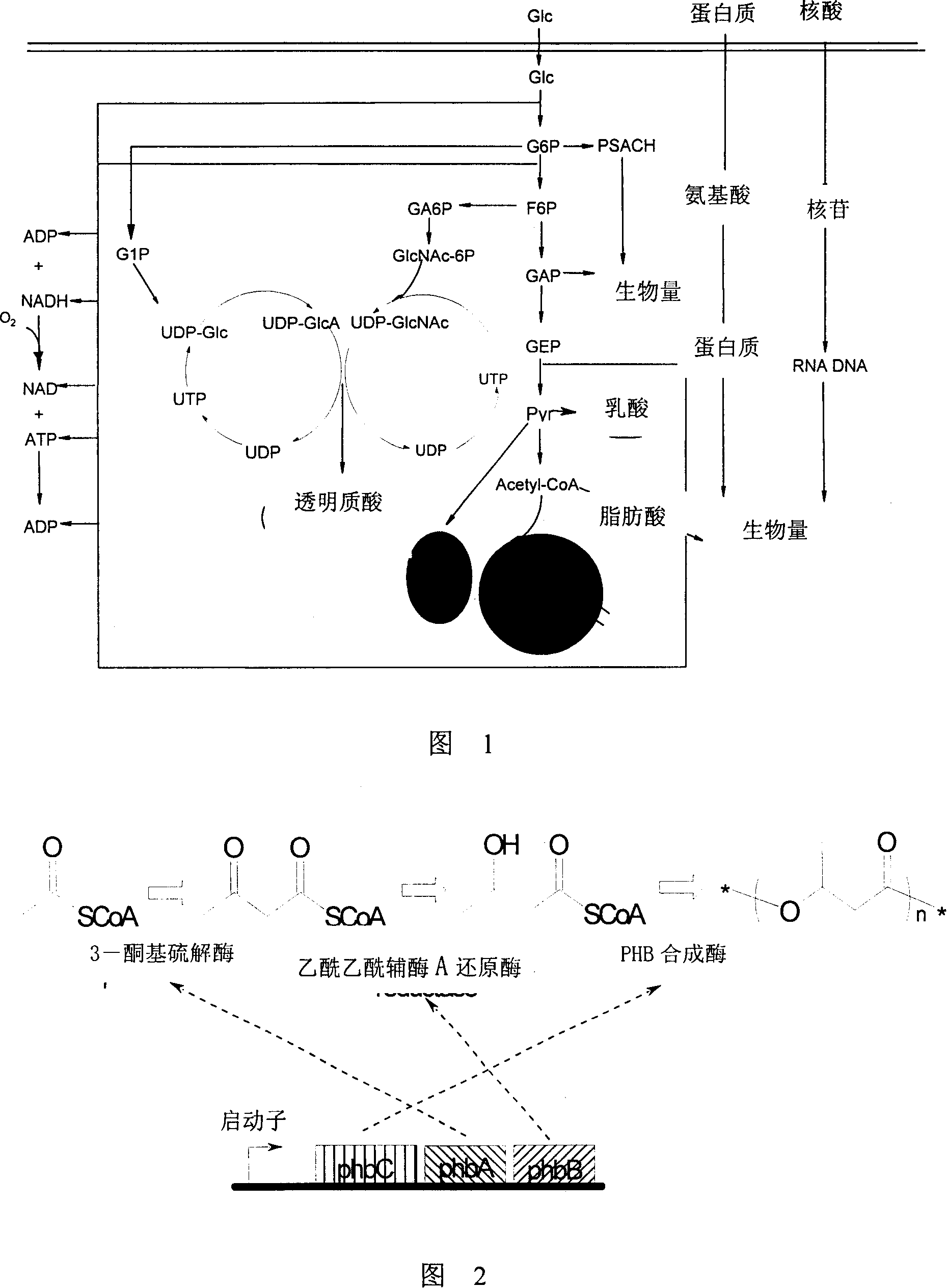

A technology of bacillus and streptococcus, applied in the field of hyaluronic acid production, can solve the problems of limiting hyaluronic acid production, cell toxicity, low dissolved oxygen, etc., to increase hyaluronic acid production, reduce lactic acid production, and promote synthesis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

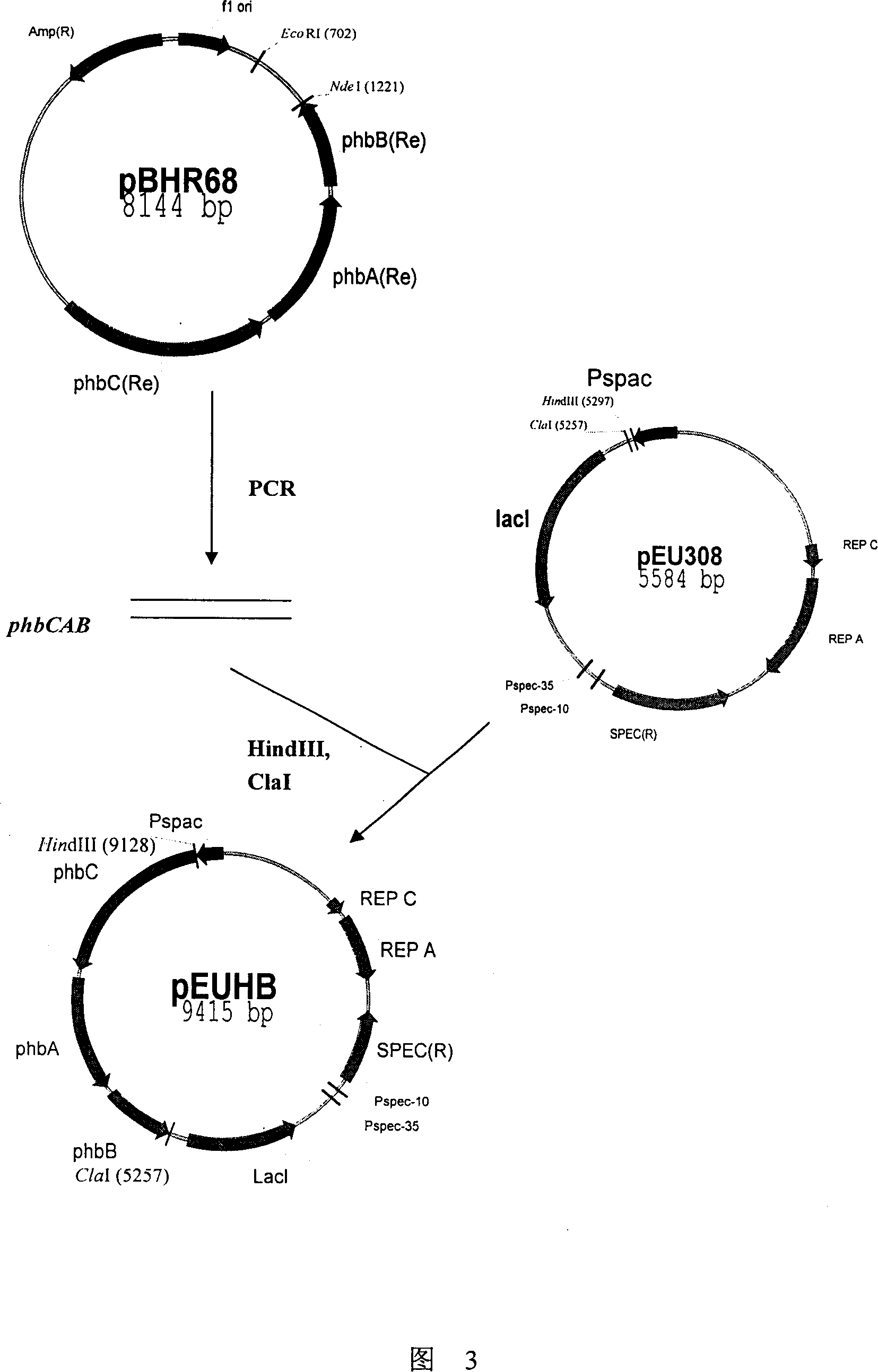

[0018] Embodiment 1, the construction of the vector pEUHB containing phbCAB gene

[0019] Strains: Escherichia coli E.coli JM109

[0020] The medium used for constructing the plasmid was (g / l): peptone 10, yeast extract 5, NaCl 10, spectinomycin 100 μg / l.

[0021] The process of constructing pEUHB is shown in Figure 3, including the following steps: 1) Under standard polymerase chain reaction conditions, use the pBHR68 plasmid (supplied by Steinbüchel of Münster University in Germany) as a template and P phbCAB -up: ATA AAGCTT (HindIII)AAGGAGGATGGCGACCGGCAAAGGC and P phbCAB -do:GTT ATCGAT (Cla I) CGGCAGGTCAGCCCATAT is a primer to obtain a 3884bp DNA amplification fragment, and its gene sequence is SEQ ID NO: 1 in the gene sequence list.

[0022]PCR reaction conditions: 96°C for 45 seconds, 66°C for 1 minute, 72°C for 4 minutes and 30 seconds, a total of 30 cycles.

[0023] 2) The amplified DNA fragment containing the phbCAB gene was digested with restriction endonuclease...

Embodiment 2

[0024] Embodiment 2, the preparation of Streptococcus zooepidemicus competent cell and electrotransformation method

[0025] Strains: Streptococcus zooepidemicus ATCC 39920

[0026] The medium used in the transformation was THYB (g / l): todd-hewitt broth 36.4, yeast extract 0.5% (w / v), spectinomycin 100 mg / l.

[0027] 1) Preparation of Competent Cells

[0028] 1) Cultivate Streptococcus zooepidemicus ATCC 39920 overnight in THYB medium;

[0029] II) it is inoculated into the fresh THYB substratum of 50ml, after inoculation D 530 No more than 0.05, cultivated to OD 530 About 0.25 or so;

[0030] III) Add hyaluronidase 0.4 mg / ml half an hour before the end of the culture;

[0031] IV) 4°C, 8000g, centrifuge for 10 minutes, discard the supernatant, and resuspend the cells with 20mL 0.5M sucrose solution;

[0032] V) Centrifuge at 8000g for 10 minutes at 4°C, discard the supernatant, resuspend the cells with 1mL of 0.5M sucrose solution, centrifuge again, and discard the supe...

Embodiment 3

[0041] Embodiment 3, the detection of PhbB (acetoacetyl-CoA reductase) enzymatic activity in recombinant bacteria

[0042] Strains: Recombinant Streptococcus zooepidemicus

[0043] Foreign gene: phbCAB

[0044] The medium used was THYB (g / l): todd-hewitt broth 36.4, yeast extract 0.5% (w / v), spectinomycin 100 mg / l, IPTG 20 mM.

[0045] 1) Enzyme activity assay method

[0046] The total reaction volume is 500ul, including 12.5ul 10mmol / l NADPH, 12.5ul7mmol / l acetyl-CoA and 425ul buffer (120mmol / l potassium phosphate, 24mmol / l magnesium chloride, 1mmol / l dithiothreitol), first at 30°C Preheat for 1 minute, then add 50ul enzyme crude extract, and immediately detect the change of absorbance at 340nm. One PhbB enzyme activity unit (U) is defined as the degradation of 1umol NADPH in 1 minute. The preparation of the enzyme crude extract is as follows: the cells were cultured at 37°C for 14 hours under the condition of adding IPTG, the supernatant was discarded by centrifugation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com