A method for preparing hollow balls and hollow balls with composite structures by a template process

A technology of composite structure and template method, which is used in the field of organic hollow spheres and composite hollow spheres, metals, and the preparation of inorganic substances, and can solve the problem that polymers cannot be assembled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Example 1 Preparation of hollow spheres of polystyrene-polyacrylic acid / titanium dioxide composite structure and titanium dioxide hollow spheres

[0139] Polystyrene-polyacrylic acid hollow sphere template, the outer layer of the hollow spherical shell is polystyrene, the inner layer is polyacrylic acid, the outer diameter is 500nm, and the thickness of the shell layer is 100nm. Take 0.1g of template particles and disperse them in 1g of tetrabutyl titanate, perform saturated adsorption for 4 hours, settle down the hollow spheres adsorbed with tetrabutyl titanate with a high-speed centrifuge, add 10g of water in ethanol solution (40wt%), and hydrolyze After reacting for 4 hours, a hollow sphere with a composite structure is obtained in which the polystyrene-polyacrylic acid hollow sphere is used as a template and titanium dioxide is grown on the inner layer of the shell. After removing the polystyrene and polyacrylic acid from the hollow sphere of this composite structur...

Embodiment 2

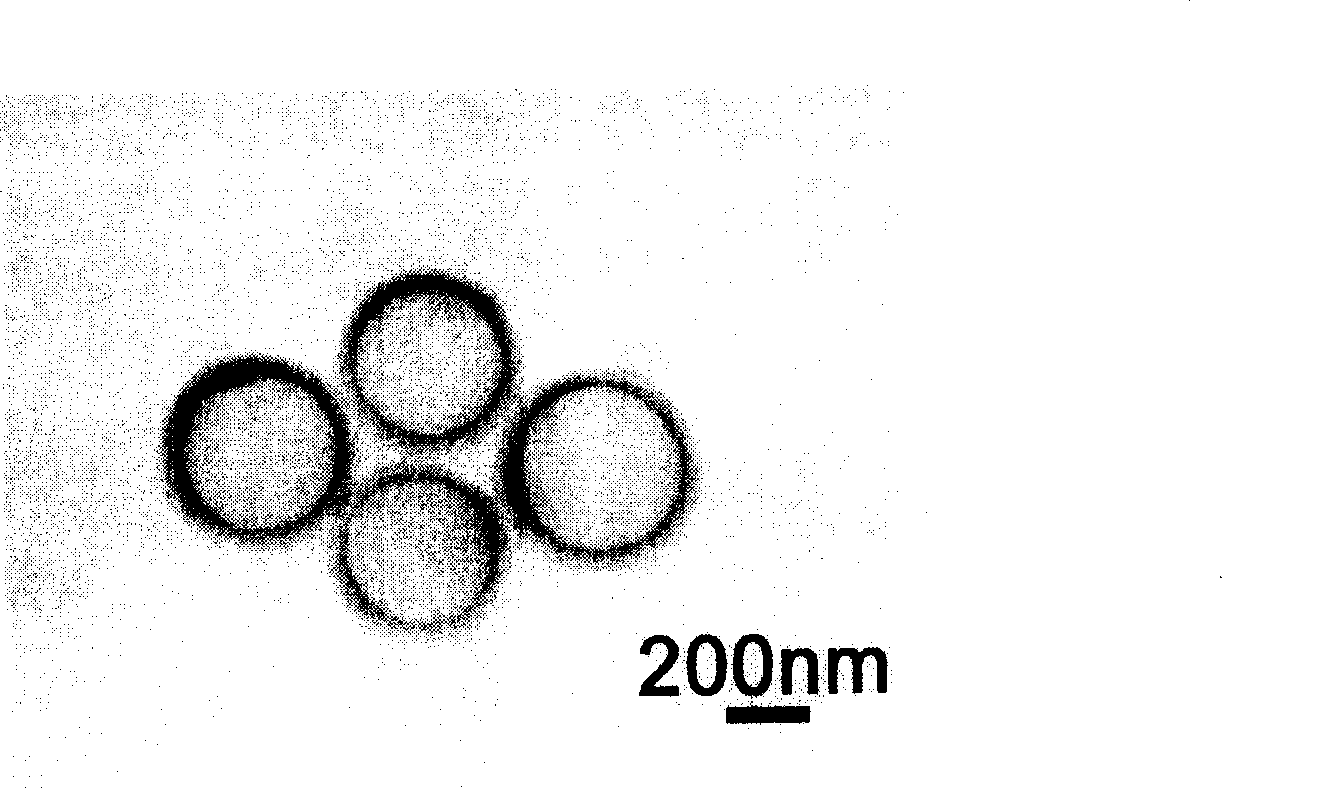

[0141] Example 2 Preparation of hollow spheres with polystyrene-polymethacrylic acid / magnetic Fe3O4 composite structure and Fe3O4 hollow spheres

[0142] 0.1g of polystyrene-polymethacrylic acid hollow structure emulsion particles, whose outer diameter is 1000nm, and the thickness of the shell is 150nm, is dispersed in 1g of 25wt% ferric chloride and 19wt% ferrous chloride mixed solution, saturated After 4 hours of adsorption, the polymer hollow spheres that have absorbed the solution were centrifuged and settled in a high-speed centrifuge, and then dispersed in 10g of 15wt% ammonia water, and hydrolyzed for 4 hours to obtain polystyrene-polymethacrylic acid hollow spheres as templates. The hollow sphere of composite structure in which ferric oxide grows in the inner layer of the shell. After removing polystyrene and polymethacrylic acid from the hollow sphere of this composite structure with chloroform, a hollow sphere of ferric oxide was obtained. The results of the transmi...

Embodiment 3

[0143] Example 3 Preparation of hollow spheres of polymethyl methacrylate-polyacrylic acid / calcium carbonate composite structure and calcium carbonate hollow spheres

[0144] 0.1g of polymethyl methacrylate-polyacrylic acid hollow structure emulsion particle, its external diameter is 100nm, and the thickness of shell is 20nm, is dispersed in the calcium chloride solution of 15wt%, saturated adsorption 4 hours, will adsorb chlorine The hollow balls of the calcium chloride solution are centrifugally settled in a high-speed centrifuge, dispersed in 10g of 15wt% sodium carbonate aqueous solution, adjusted to a pH value of 9 with 25wt% of ammonia water, and reacted for 4 hours to obtain polymethyl methacrylate-polyacrylic acid hollow balls. The ball is a hollow ball with a composite structure in which template calcium carbonate grows on the inner layer of the shell. After removing the polymethyl methacrylate and polyacrylic acid from the hollow sphere of this composite structure wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com