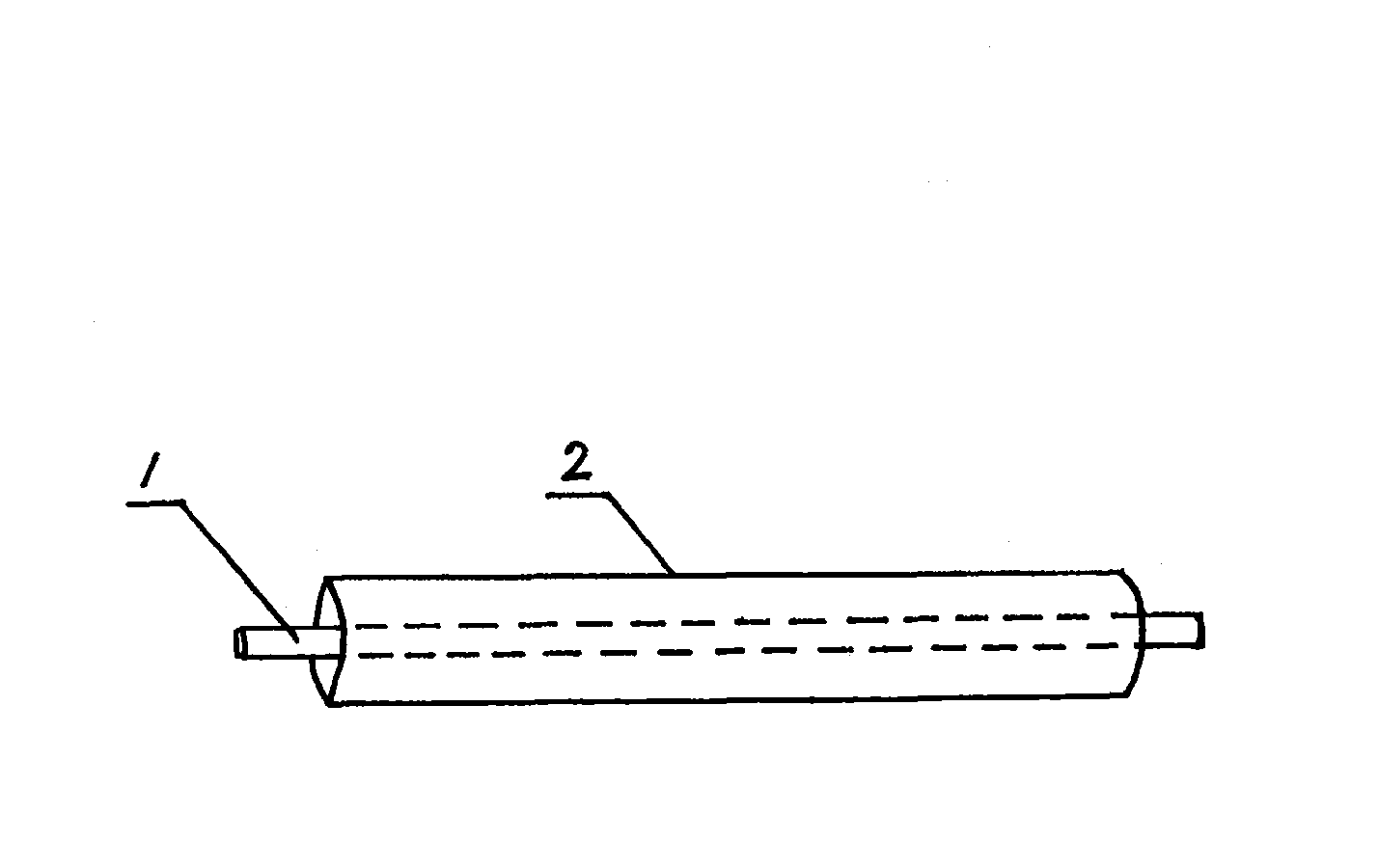

Making method of nano thermal electric material with coaxial cable structure

A coaxial cable and thermoelectric material technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, thermoelectric devices, etc., can solve the problems of low thermoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) In a reaction vessel, add 0.1 g of tellurium powder, 0.12 g of bismuth chloride, 200 ml of distilled water, 0.5 g of sodium p-dodecylbenzenesulfonate, 1.5 g of sodium hydroxide, and 1 g of sodium borohydride. Stir and control the temperature of the reactor at 50°C and keep it warm for 48h to obtain Bi 2 Te 3 Nano core material;

[0021] (2) will Bi 2 Te 3 The nanopowder is taken out, then washed with ethanol and distilled water and then dried;

[0022] (3) The washed Bi 2 Te 3 Put the nanopowder into a 200ml beaker, add 100ml of water, and stir with a magnetic force. Then add 0.1 g of surface treatment reagent mercaptoacetic acid, and stir for 5 hours at room temperature for surface treatment.

[0023] (4) The Bi after surface treatment agent treatment 2 Te 3 The nano-powders were washed and dried with ethanol and distilled water respectively, and then added to the autoclave, followed by adding 0.1 g of tellurium powder, 0.12 g of antimony chloride, 1.5 g o...

Embodiment 2

[0025] (1) In a reaction vessel, add 0.1 g of tellurium powder, 0.12 g of antimony chloride, 200 ml of distilled water, 0.5 g of sodium p-dodecylbenzenesulfonate, 1.5 g of sodium hydroxide, and 1 g of sodium borohydride. Stir and control the temperature of the reactor at 100°C, keep it warm for 12h, and obtain Sb 2 Te 3 Nano core material;

[0026] (2) Sb 2 Te 3 The nanopowder is taken out, then washed with ethanol and distilled water and then dried;

[0027] (3) The washed Sb 2 Te 3 Put the nanometer powder into a 200ml beaker, add 100ml of ethanol, and stir with a magnetic force. Then add 20 grams of surface treatment reagent mercaptopropionic acid, and stir for 5 hours at room temperature for surface treatment.

[0028] (4) Sb treated with surface treatment agent 2 Te 3 The nano-powders were washed and dried with ethanol and distilled water respectively, and then added to the high-pressure reaction kettle, followed by adding 0.1 g of tellurium powder, 0.12 g of bis...

Embodiment 3

[0030] (1) In the reaction vessel, add 0.1 g of selenium powder, 0.12 g of antimony nitrate, 200 ml of distilled water, 0.5 g of sodium p-dodecylbenzenesulfonate, 1.5 g of sodium hydroxide, and 1 g of sodium borohydride. Stir and control the temperature of the reactor at 80°C, keep it warm for 18h, and obtain Sb 2 Se 3 Nano core material;

[0031] (2) Sb 2 Se 3 The nanopowder is taken out, then washed with ethanol and distilled water and then dried;

[0032] (3) The washed Sb 2 Se 3 Put the nanopowder into a 200ml beaker, add 100ml of water, and stir with a magnetic force. Then add 10 grams of surface treatment reagent bismercaptooxalic acid, and stir for 5 hours at room temperature for surface treatment.

[0033] (4) Sb treated with surface treatment agent 2 Se 3 The nano-powders were washed and dried with ethanol and distilled water respectively, and then added into the autoclave, followed by adding 0.1 g of tellurium powder, 0.06 g of bismuth chloride, 0.06 g of fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com