Method of processing semi-conductor industrial waste water

A technology for industrial wastewater and treatment methods, which is applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, semi-permeable membrane separation, etc. It can solve the problems of easy pollution of filtration structures, unstable effluent quality, and high operating energy consumption. To achieve the effect of easy automatic control, harmless waste water, and reliable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

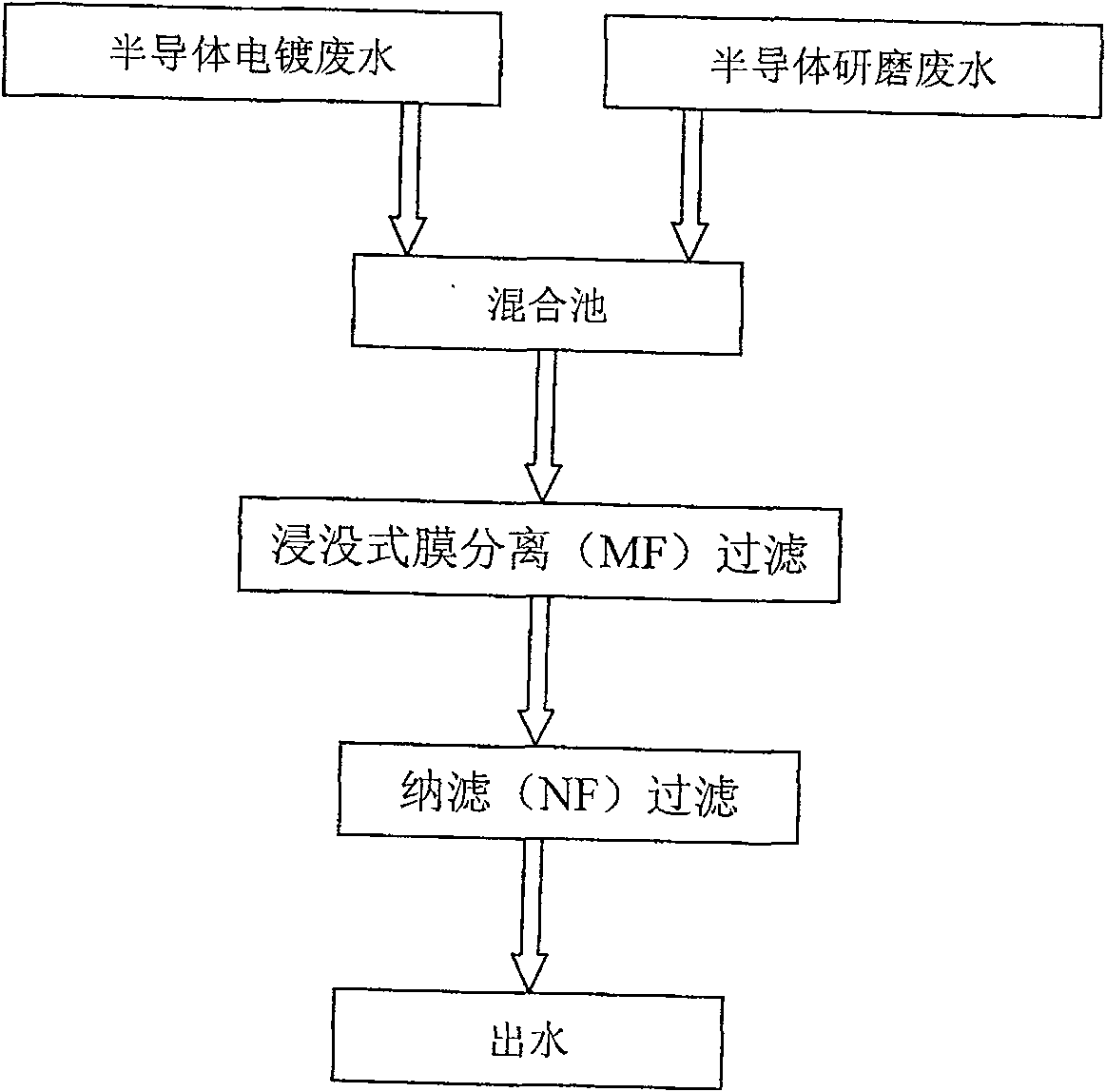

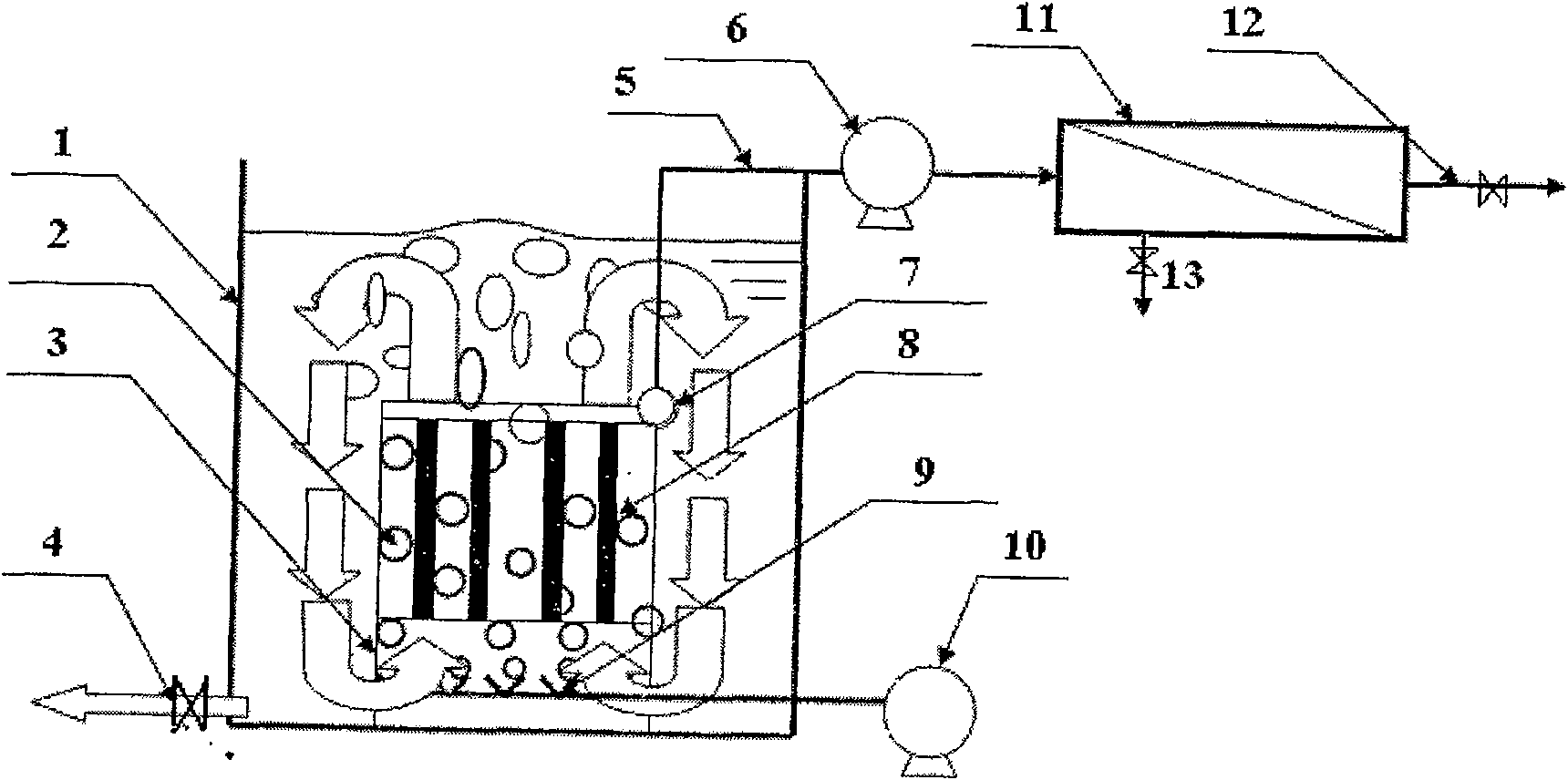

[0025] Such as figure 1 As shown in the process flow, the silicon wafer electroplating wastewater produced by a microelectronics company's integrated circuit and the grinding wastewater of the packaging shell are discharged into the mixing pool to become mixed wastewater. The water quality is shown in Table 2. The submerged flat-plate membrane filter device designed and manufactured by Wuxi Ningyang Environmental Protection Technology Co., Ltd., its Chinese patent application number is 200720035758.4, and its structure diagram is shown in figure 2. The filter membrane used in this equipment is a flat submerged organic polymer material microfiltration membrane (MF), its filter pores are between 0.04 and 0.5 μm, and the operating pressure is less than 20KPa, which can effectively remove suspended solids, The micelles, particles and most of the organic impurities, the water quality of the above-mentioned semiconductor processing mixed wastewater after being filtered by the subm...

Embodiment 2

[0034] An electronic technology company specializing in the development and production of semiconductor discrete devices. The water quality of the grinding wastewater and discrete device electroplating wastewater generated by its semiconductor manufacturing is listed in Table 3 after being discharged into the mixing tank. The packaging shell of semiconductor discrete devices is first electroplated with copper and then electroplated with nickel. The above-mentioned semiconductor processing mixed wastewater in the mixing tank is pumped into the submerged membrane filter device for treatment, and the filtered water quality is shown in Table 3 ("-" in the table means that it cannot be detected, and its value is close to zero). The permeate enters the nanofiltration filtration device for further filtration treatment, and the finally filtered water can be reused directly. The water quality is shown in Table 3.

[0035] Table 3 The water quality of the above-mentioned semiconductor p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com