Radiation-sensitive resin composition, method for forming spacer and spacer

A curable resin and composition technology, applied in nonlinear optics, patterned surface photoengraving process, semiconductor/solid-state device manufacturing, etc. Oven and other problems, to achieve the effect of excellent compressive strength, excellent friction resistance and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0186] As the solvent used in the preparation of the first composition, each component is used to uniformly dissolve (A) polymer, (B) polymerizable unsaturated compound and (C) radiation-sensitive polymerization initiator, and optionally added other components, and Does not react with the ingredients.

[0187] Examples of such a solvent include the same solvents as the solvents that can be used to produce the above-mentioned (A) polymer.

[0188] Among such solvents, for example, alcohols, glycol ethers, glycol alkyl ether acetates, esters and diethylene glycol. Among them, for example, benzyl alcohol, 2-phenylethyl alcohol, 3-phenyl-1-propanol, ethylene glycol monobutyl ether acetate, diethylene glycol monoethyl ether acetate, diethylene glycol Diethyl ether, diethylene glycol ethyl methyl ether, diethylene glycol dimethyl ether, propylene glycol monomethyl ether, propylene glycol monomethyl ether acetate, methyl methoxypropionate, ethyl ethoxypropionate.

[0189] In addit...

Embodiment

[0403] Hereinafter, the present invention will be described more specifically by showing synthesis examples and examples, but the present invention is not limited to the following examples.

[0404] For the polymer synthesized in the synthesis example of the following polymer, the gel permeation chromatography was measured under the following conditions, the polystyrene-equivalent weight average molecular weight (Mw) and the number average molecular weight (Mn) were obtained, and the molecular weight distribution (Mw / Mn).

[0405] Device: GPC-101 (manufactured by Showa Denko Co., Ltd.)

[0406] Chromatographic column: combined with GPC-KF-801, GPC-KF-802, GPC-KF-803 and GPC-KF-804

[0407] Mobile phase: tetrahydrofuran containing 0.5% by weight phosphoric acid.

[0408] (1) Preparation and evaluation of the first composition

Synthetic example 1

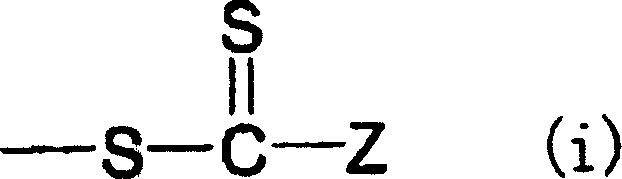

[0411] In a flask with a condenser tube and a stirrer, add 5 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile), 5 parts by weight of tetraethylthiuram disulfide as a molecular weight control agent and 200 parts by weight of diethylene glycol diethyl ether, then add 20 parts by weight of styrene, 17 parts by weight of methacrylic acid, 18 parts by weight of tricyclic [5.2.1.0 2,6 ] Dec-8-yl methacrylate and 45 parts by weight of glycidyl methacrylate, after replacing nitrogen, slowly stirred, while raising the temperature of the reaction solution to 70°C, and kept the temperature for polymerization for 4 hours. Then, 3 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile) was added, and the polymerization was continued for 3 hours to obtain a solution containing a copolymer. Mw=12000 of this resin, Mw / Mn=1.60. This resin is called "resin (A-1)".

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com