Metal corsslinking molecular film-forming bi-component water carpentry paint and preparation method thereof

A water-based wood lacquer and metal cross-linking technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as difficulty in promotion, high cost, and difficulty in obtaining raw materials, and achieve transparent and uniform appearance, excellent stability, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

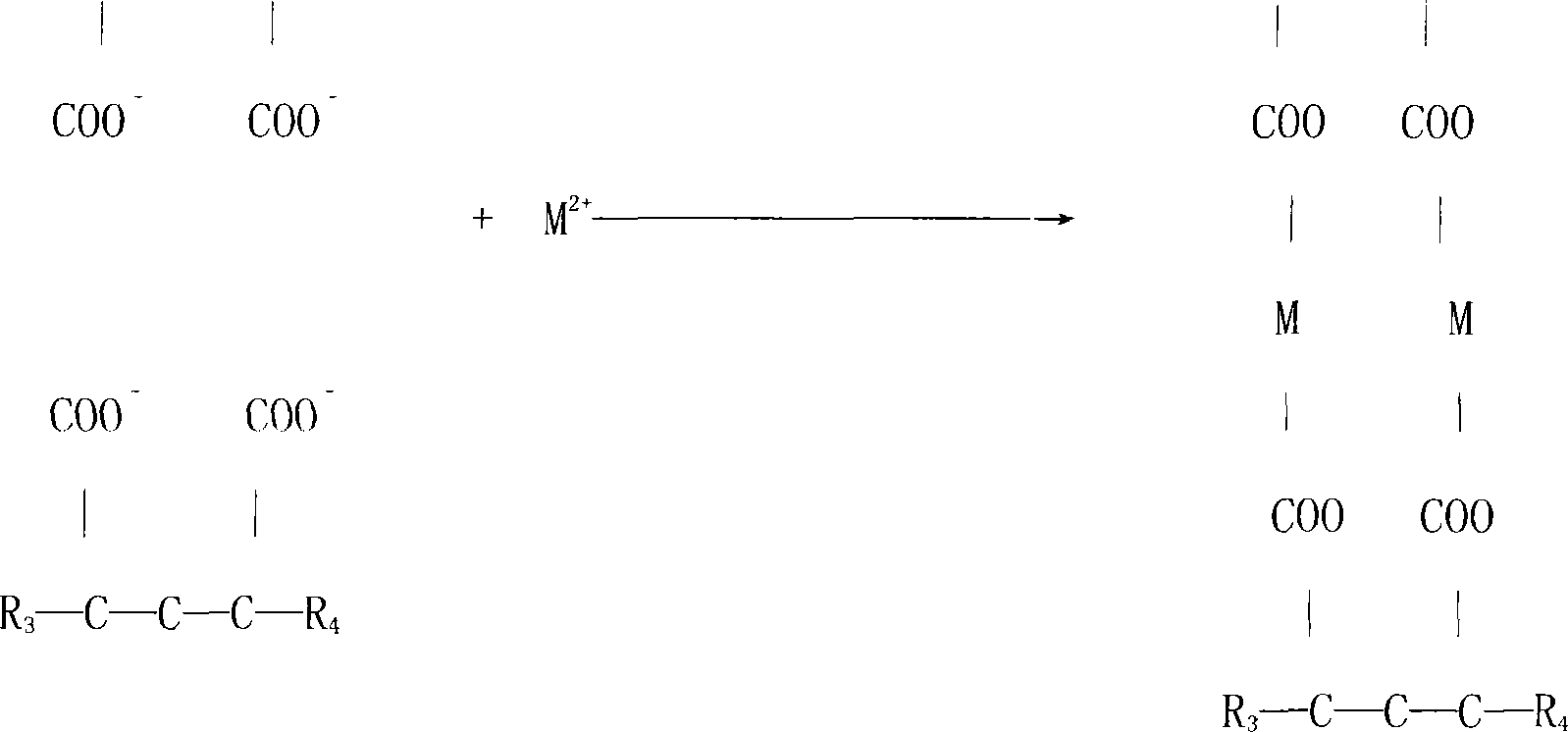

Method used

Image

Examples

Embodiment 1

[0082] Embodiment one, the preparation of bright varnish

[0083] 1. Main paint A component:

[0084] (1) Synthesis of water-soluble water-based resin I:

[0085] Table 1 Water-based resin I formula table

[0086] Composition

[0087] 12 parts of unsaturated monomer butyl acrylate, 30 parts of methyl methacrylate and 18 parts of carboxylic acid-containing monomer acrylic acid are carried out solution polymerization in the cosolvent ethylene glycol butyl ether according to the proportioning in Table 1, and the ethylenic monomer obtained The bulk copolymer solution was distilled under reduced pressure to remove low-molecular substances, then neutralized with 10 parts of ammonia water, and added 10 parts of deionized water to obtain completely water-soluble water-based resin I.

[0088] (2) Preparation of main paint:

[0089] The composition of table 2 main paint

[0090] recipe ingredients

[0091] Add water-soluble water-based resin I into the container...

Embodiment 2

[0101] Embodiment two, the preparation of matte varnish

[0102] 1. Main paint A component:

[0103] (1) Preparation of water-soluble water-based resin II

[0104] Table 5 Water-based resin II formula table

[0105] Composition

parts by weight

Decyl acrylate

10.0

22.0

8.0

10.5

5.5

44.0

[0106] According to the ratio in Table 5, 10 parts of unsaturated monomer decyl acrylate, 22 parts of styrene and 8 parts of carboxylic acid monomer methacrylic acid are solution polymerized in the cosolvent cyclohexanone to obtain the ethylenic monomer copolymer The solution was distilled under reduced pressure to remove low-molecular substances, then neutralized with 5.5 parts of ethylenediamine, and added 44 parts of distilled water to obtain completely water-soluble water-based resin II.

[0107] (2) Preparation of main pa...

Embodiment 3

[0119] Embodiment three, the preparation of colored paint:

[0120] 1. Main paint A component:

[0121] (1) Synthesis of water-soluble water-based resin III:

[0122] Table 9 Formula table of water-based resin III

[0123] Composition

[0124]According to the ratio in Table 9, 18 parts of unsaturated monomer acrylamide and 2 parts of carboxylic acid-containing monomer β-carboxyethyl acrylate are firstly solution-polymerized in the cosolvent diglyme, and the obtained ethylenic mono The bulk copolymer solution was distilled under reduced pressure to remove low-molecular substances, and neutralized by adding 1 part of ethanolamine and 78 parts of tap water to obtain water-based resin III.

[0125] (2) Configuration of main paint

[0126] The composition of table 10 main paint

[0127] recipe ingredients

[0128] Add water-soluble water-based resin III into the container according to the ratio in Table 10, start stirring, add various water-based additives,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com