High-temperature and strong base resistant clausii bacillus cereus, excretive proteolytic enzyme and preparation

A technology of Bacillus clausii and Bacillus, applied in the direction of bacteria, hydrolytic enzymes, and microbial-based methods, can solve the problem of low anti-oxidation and anti-SDS performance, enzymatic properties that are difficult to meet the needs of the development of the washing industry, and unsatisfactory It has large-scale industrial development potential and other issues, and achieves the effects of good thermal stability and pH stability, good thermal stability, and wide pH stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

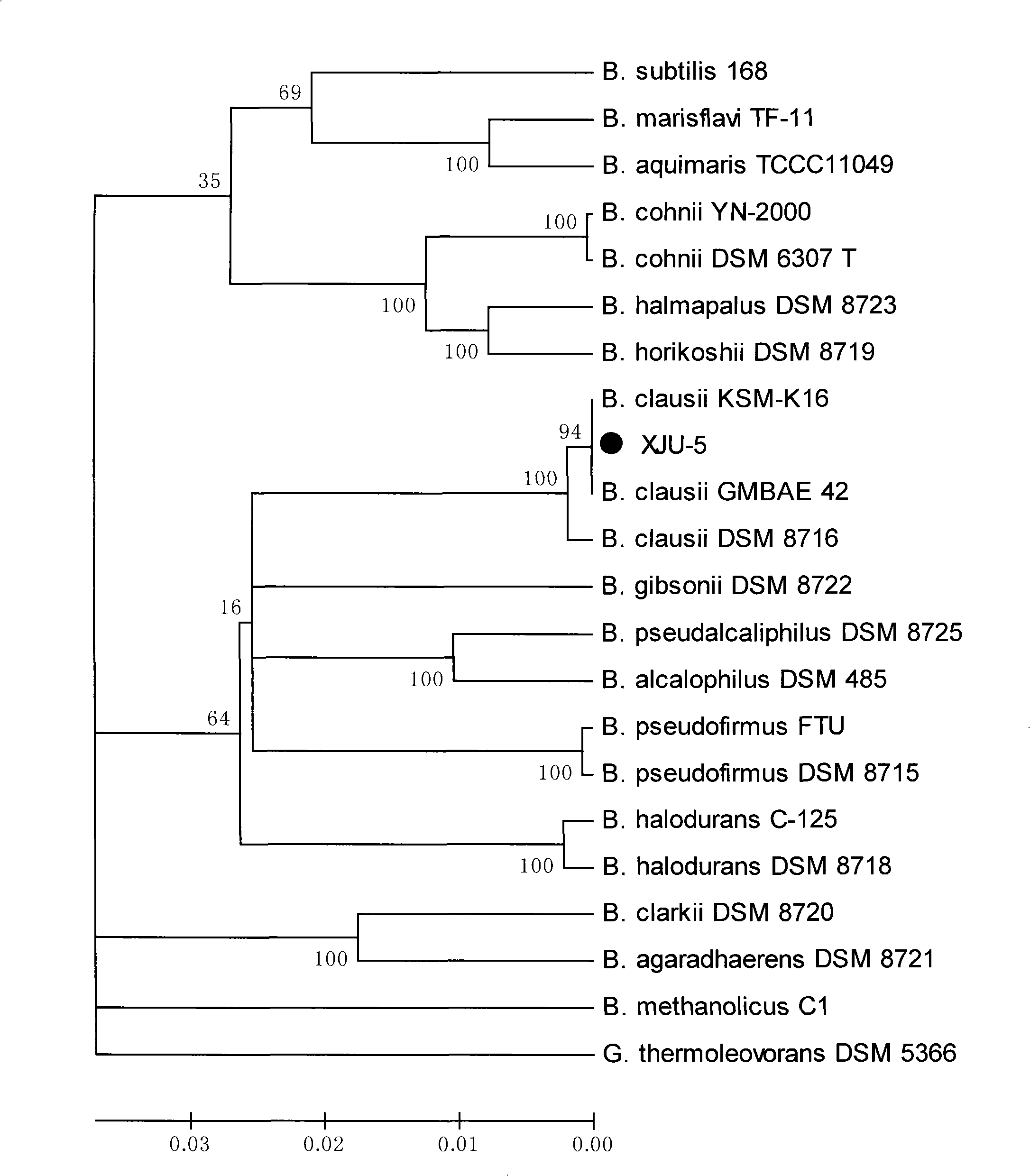

[0132] Example 1: Cultivation and screening of high-temperature alkaline protease-producing bacteria B.ciausii XJU-5

[0133] 1. Sample collection

[0134] Samples were collected from saline water in Turpan, Xinjiang.

[0135] 2. Isolation of strains

[0136] Prepare plate medium (g / l): 2.0% wheat straw, 0.2% NH 4 NO 3 , 0.2%K 2 HPO 4 , 0.02% MgSO 4 ·7H 2 O, 0.5% yeast extract, 1.8% agar powder, pH10.5. The above medium was added at 1.05kg / cm 2 , 121°C, autoclaved for 20 minutes.

[0137] Centrifuge the collected water sample at 8000rpm for 10min, discard the supernatant, dissolve the precipitate with sterilized physiological saline, and prepare the suspension at 10 1 , 10 3 , 10 4 , 10 5 , 10 7 Make 5 dilution gradients, take 0.2mL of each dilution sample solution and spread evenly on the above medium (pH10.5) plate, culture at 38°C for 18 hours to obtain a single colony, pick a single colony with an inoculation needle Draw a line and connect to the above-menti...

Embodiment 2

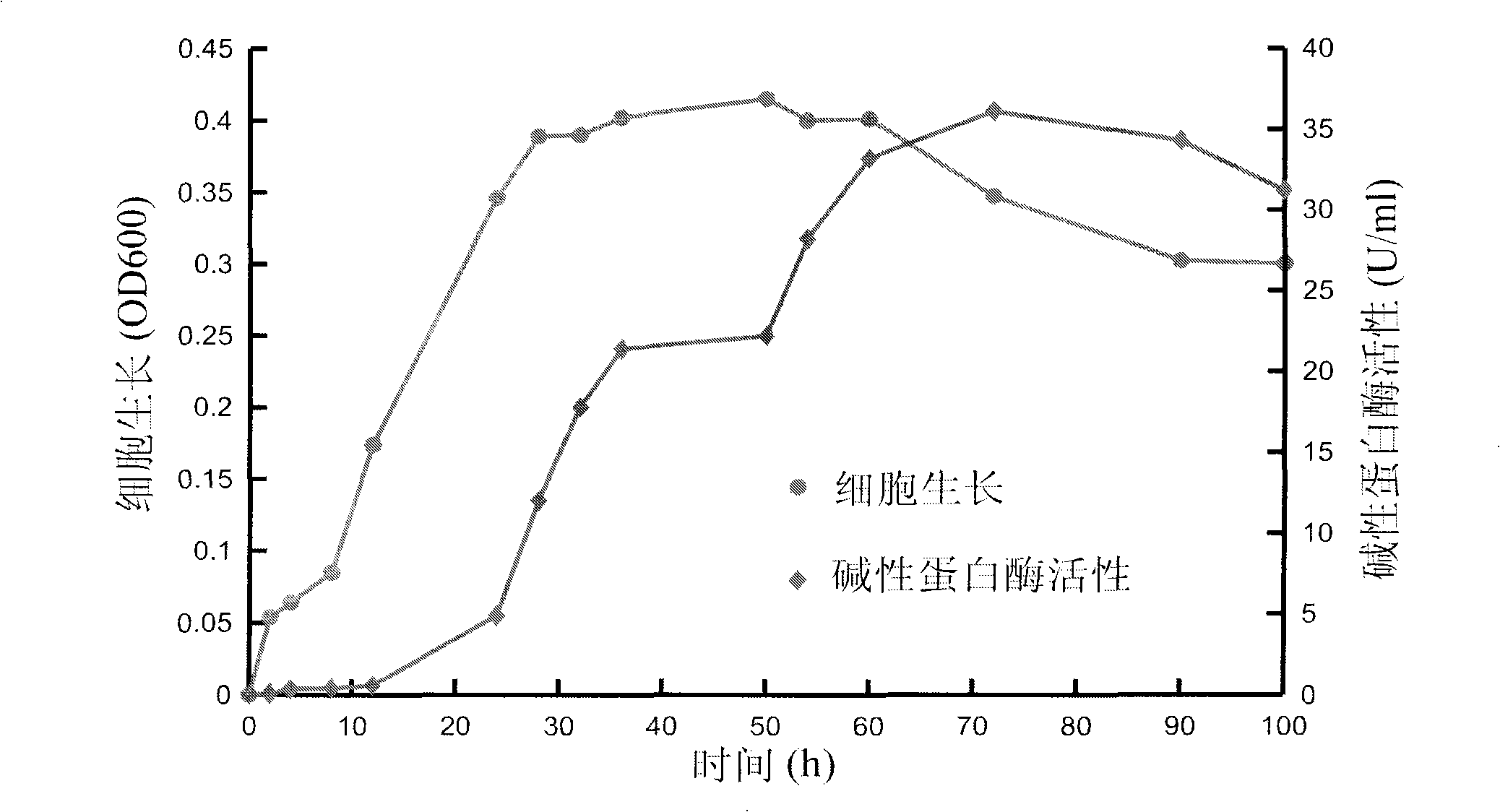

[0142] Embodiment 2: Fermentation culture of high temperature alkaline protease producing bacteria B.clausii XJU-5

[0143] The culture medium is the basis of fermentation technology. On the basis of laboratory research, the medium screening and optimization of industrial pilot test research are carried out, and the optimization is carried out on the basis of basic fermentation culture medium.

[0144] 2. Basic fermentation medium: peptone 10g, yeast extract powder 5g, sodium chloride 5g, dipotassium hydrogen phosphate 1g, magnesium sulfate crystal 0.2g and water 1000ml.

[0145] Note: pH10.0-11.0, adjust the pH of the sterilized medium with sterilized 10% sodium carbonate solution.

[0146] (1) Optimization of fermentation medium for enzyme production

[0147] 1. Effect of carbon source on enzyme production

[0148] Choose no carbon source, glucose, yeast extract, corn flour, sucrose, and starch to replace the yeast extract powder in the basic culture solution to make diffe...

Embodiment 3

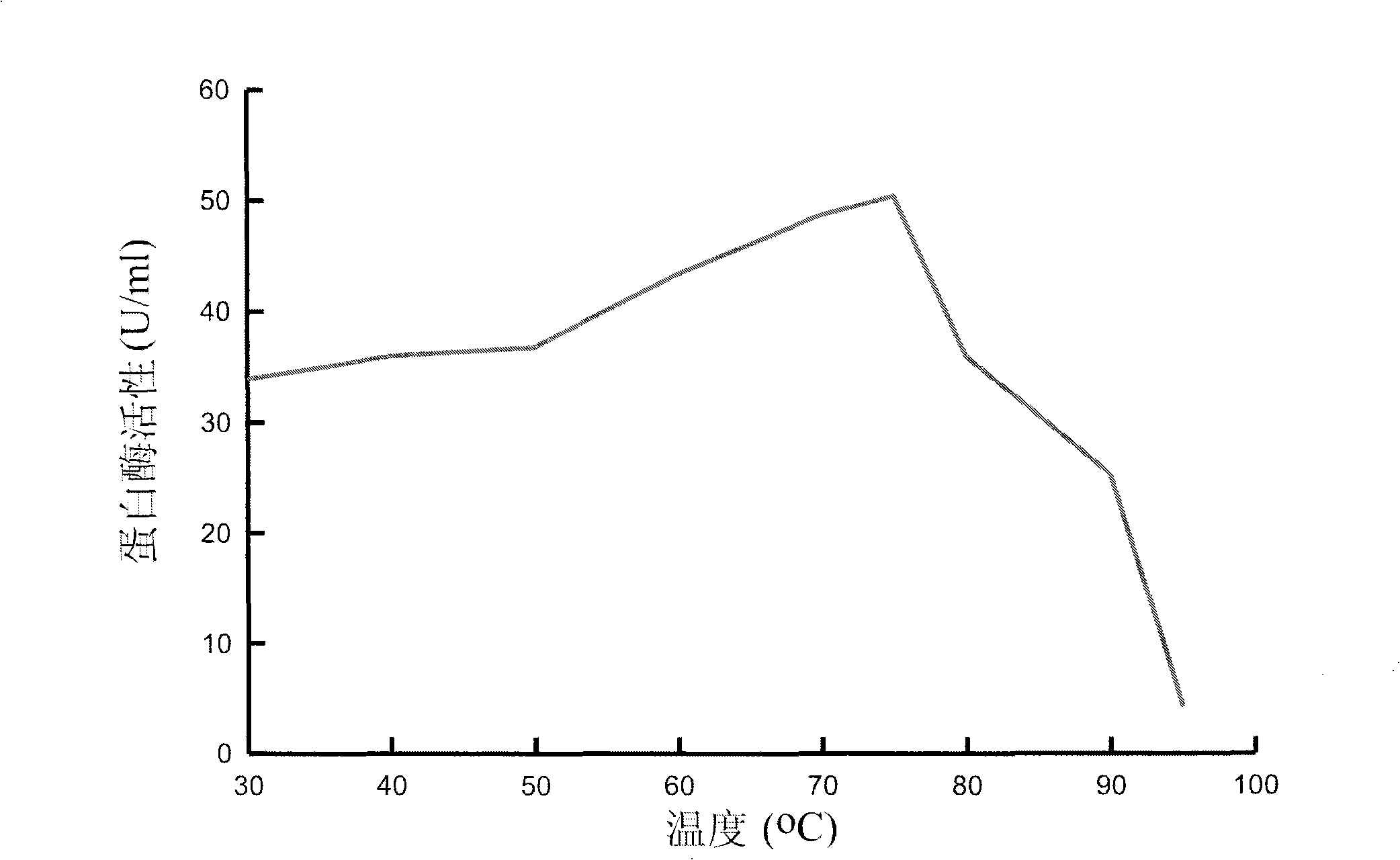

[0159] Embodiment 3: the measurement method of high temperature alkaline protease activity

[0160] According to the "Industrial Standards of the People's Republic of China" QB / T 1803, 1804-93, QB / T 1805, 1806-93 issued by the Ministry of Light Industry of the People's Republic of China on 1993-07-29 and implemented on 1994-03-01, industrial enzymes General test method for preparations, during the test, the temperature is set at 40°C and the pH is 10.5.

[0161] 1.1 Definition

[0162] 1 g of solid enzyme powder (or 1 mL of liquid enzyme), under certain temperature and pH conditions, hydrolyzes casein for 1 min to produce 1 μg of tyrosine, which is an enzyme activity unit, expressed in u / g (u / mL).

[0163] 1.2 Forint method

[0164] 3.2.1 Principle

[0165] Under certain temperature and pH conditions, protease hydrolyzes the casein substrate to produce amino acids containing phenolic groups (such as: tyrosine, tryptophan, etc.), and under alkaline conditions, the Folin reag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com