One-dimensional embedded with hetero-junction photocatalyst intermingle with TiO2 and preparation and use thereof

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as photocatalytic immobilization, and achieve large adsorption performance , simplified production process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

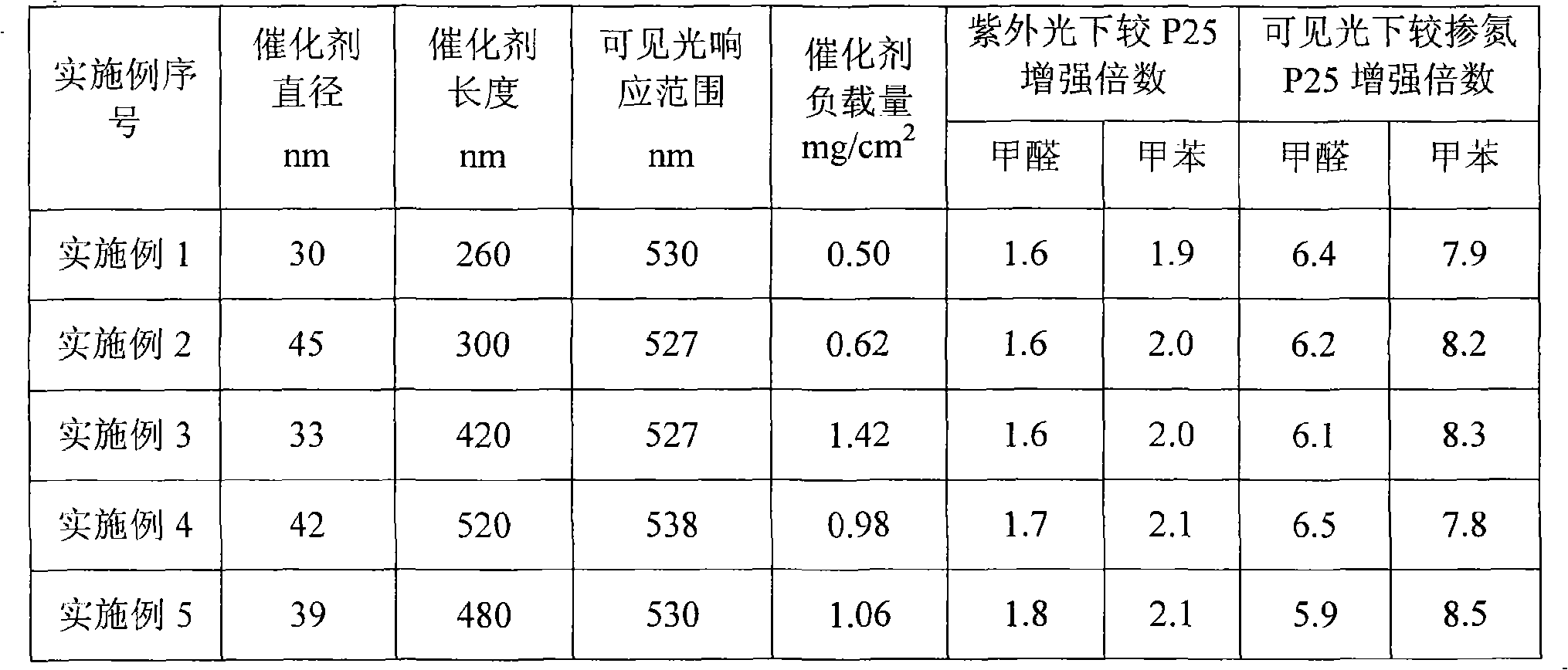

Embodiment 1

[0049] Gold was selected as the crystal growth catalyst, ammonia gas as the non-metallic doping source, and titanium tetraisopropoxide as TiO 2 The precursor, tin oxide is the semiconductor corresponding to the heterojunction, and tin chloride is the precursor of tin oxide. Heat titanium tetraisopropoxide to 60°C and tin chloride to 40°C. The gold-loaded glass is placed in the constant temperature zone in the middle of the tube furnace, and helium gas is introduced at a flow rate of 100ml / min. Raise the temperature to 400°C and keep it warm for 0.5h. Open the valve, bring the gasified titanium tetraisopropoxide into the vaporized titanium tetraisopropoxide by helium, and feed ammonia gas at the same time, the flow rate is 150ml / min, and grow TiO 2 For nanowires, the growth temperature is 400° C., and the growth time is 0.5 h. Control the gas source through the valve, stop the gasification of titanium tetraisopropoxide and ammonia gas, and switch to the gasification of tin c...

Embodiment 2

[0051] Select cobalt as crystal growth catalyst, nitrous oxide as non-metallic doping source, and n-butyl titanate as TiO 2 The precursor, zinc oxide is the semiconductor corresponding to the heterojunction, and diethyl zinc is the precursor of zinc oxide. Heat n-butyl titanate to 95°C and diethyl zinc to -18°C. The cobalt-loaded ceramics are placed in the constant temperature zone in the middle of the tube furnace, and nitrogen gas is introduced at a flow rate of 200ml / min. Raise the temperature to 450°C and keep it warm for 0.5h. Open the valve, and the gasified n-butyl titanate is brought into by nitrogen gas, and nitrous oxide is introduced at the same time, with a flow rate of 80ml / min, to grow TiO 2 For nanowires, the growth temperature is 450° C., and the growth time is 3.0 h. Control the gas source through the valve, stop feeding gasified n-butyl titanate and nitrous oxide, and switch to feeding gasified diethyl zinc. 2 ZnO nanowires are grown on the top of the nan...

Embodiment 3

[0053] Select iron as crystal growth catalyst, ammonia as non-metallic doping source, n-butyl titanate as TiO 2 The precursor, tin oxide is the semiconductor corresponding to the heterojunction, and tin chloride is the precursor of tin oxide. Heat n-butyl titanate to 85°C and tin chloride to 55°C. The gold-loaded glass is placed in the constant temperature zone in the middle of the tube furnace, and nitrogen gas is introduced at a flow rate of 200ml / min. Raise the temperature to 400°C and keep it warm for 0.5h. Open the valve, and the vaporized n-butyl titanate is brought in by nitrogen gas, and ammonia gas is introduced at the same time, with a flow rate of 150ml / min, to grow TiO 2 For nanowires, the growth temperature is 500° C., and the growth time is 4.0 h. The gas source is controlled by the valve, the gasified n-butyl titanate and ammonia gas are stopped, and the gasified tin chloride is fed in instead, and the TiO 2 Growth of SnO on top of nanowires 2 For nanowires...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com