Production method of nanocrystalline TiO2 solar battery prototype device

A technology of solar cells and manufacturing methods, which is applied in the fields of semiconductors and solar photovoltaics, can solve the problems of easy moisture volatilization, long slurry stirring time, and difficulty in long-term storage, achieve high photoelectric conversion efficiency, reduce production costs, and improve controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

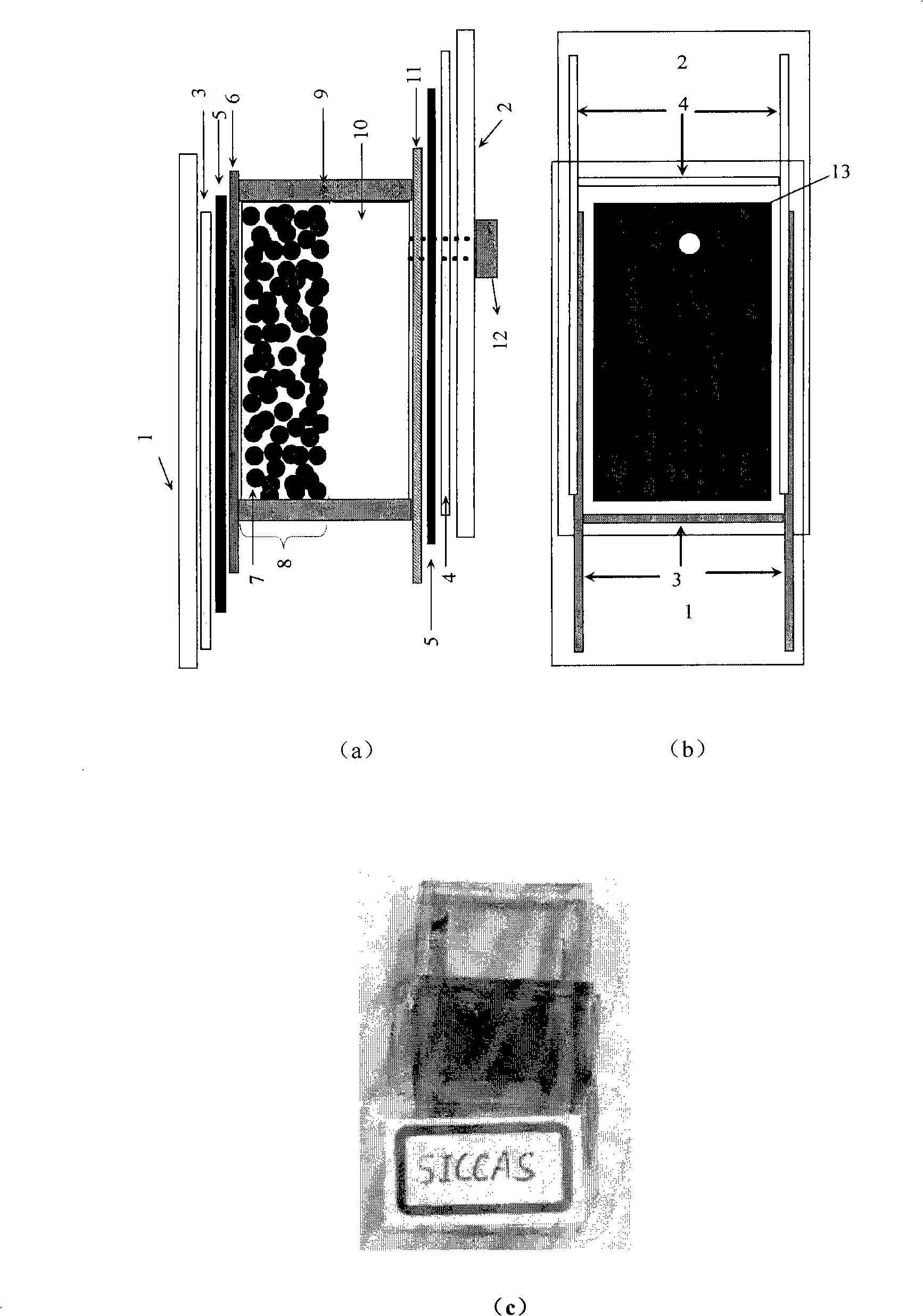

Embodiment 1

[0052] 1. Raw material preparation.

[0053] a. Transparent conductive electrode: select fluorine-doped tin oxide transparent conductive glass with a size of 2×3 cm as the electrode of the battery. The FTO glass used for the anode electrode and the counter electrode is the same size. The electrodes were soaked in hot dilute sulfuric acid (60°C) for 30 minutes, and then ultrasonically rinsed in acetone, ethanol and deionized water for 20 minutes. The processed electrodes were placed in a vacuum desiccator for later use.

[0054] b. TiO 2 Sol: Mix 15 ml of tetrabutyl titanate with a certain amount of acetylacetone, then add 40 ml of absolute ethanol, stir well to obtain a light yellow mixture A. A mixture B of 0.3 ml of hydrochloric acid, 10 ml of deionized water and 20 ml of absolute ethanol was slowly added dropwise to the mixture A under vigorous stirring, and a transparent sol was obtained after stirring for a period of time.

[0055] c. Chloroplatinic acid: Weigh 2.05 g...

Embodiment 2

[0072] 1. Raw material preparation.

[0073] d. Electrolyte (10): Weigh 0.67 grams of lithium iodide, 1.27 grams of iodine, 3.38 grams of tert-butylpyridine, and dissolve in 100 milliliters of acetonitrile-propylene carbonate mixed solution, wherein the volume ratio of acetonitrile to propylene carbonate It is 4:6.

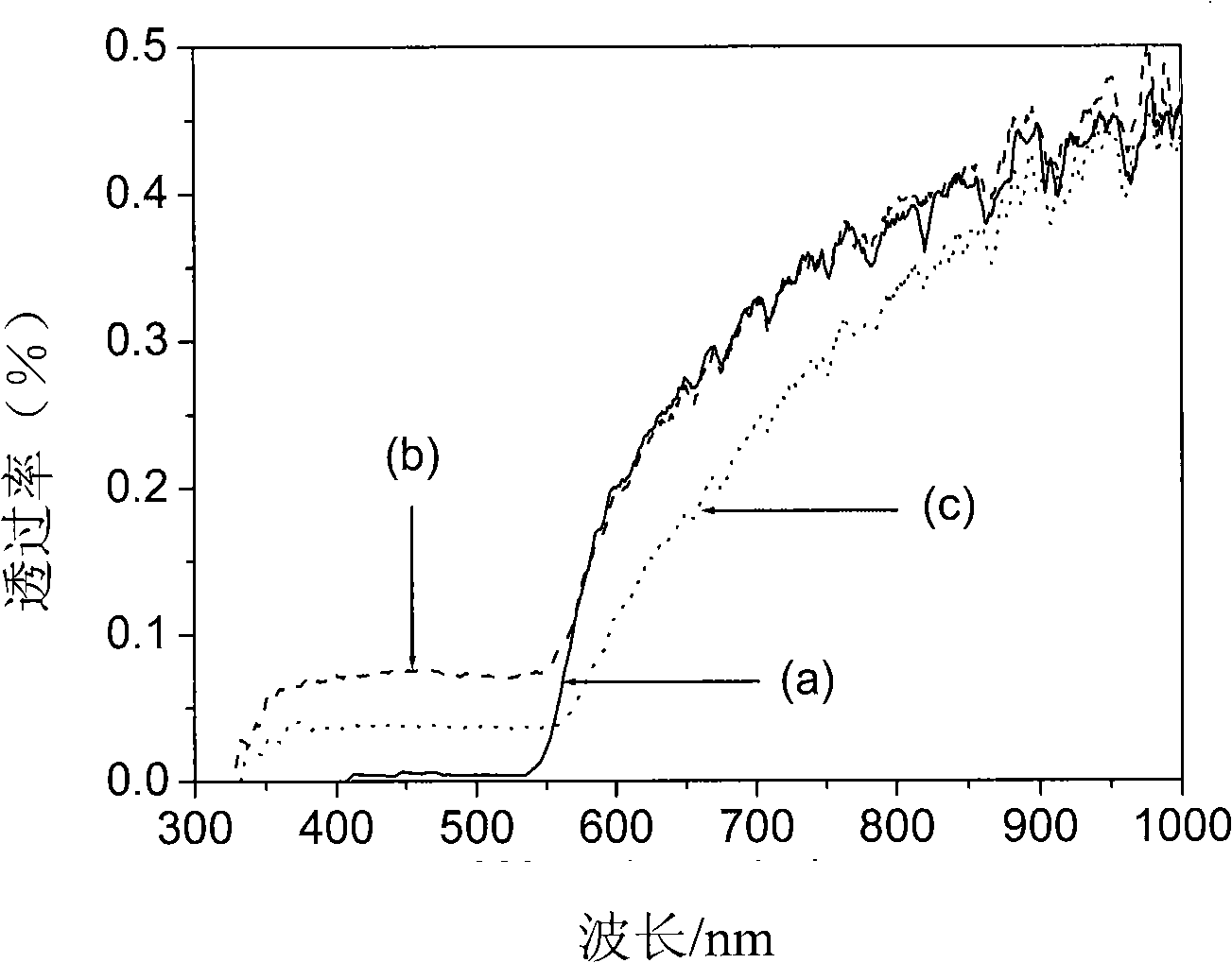

[0074] e. mercurine dye solution: measure 2 milliliters of medical red solution (2% mercurine aqueous solution) and place it in a beaker, dry it in a 105° C. oven until the moisture is completely dry, then add 5 milliliters of absolute ethanol to the beaker to obtain Mercury bromide ethanol solution with a concentration of about 0.001mol / l.

[0075] 2. Preparation of nanoporous photoanode membrane.

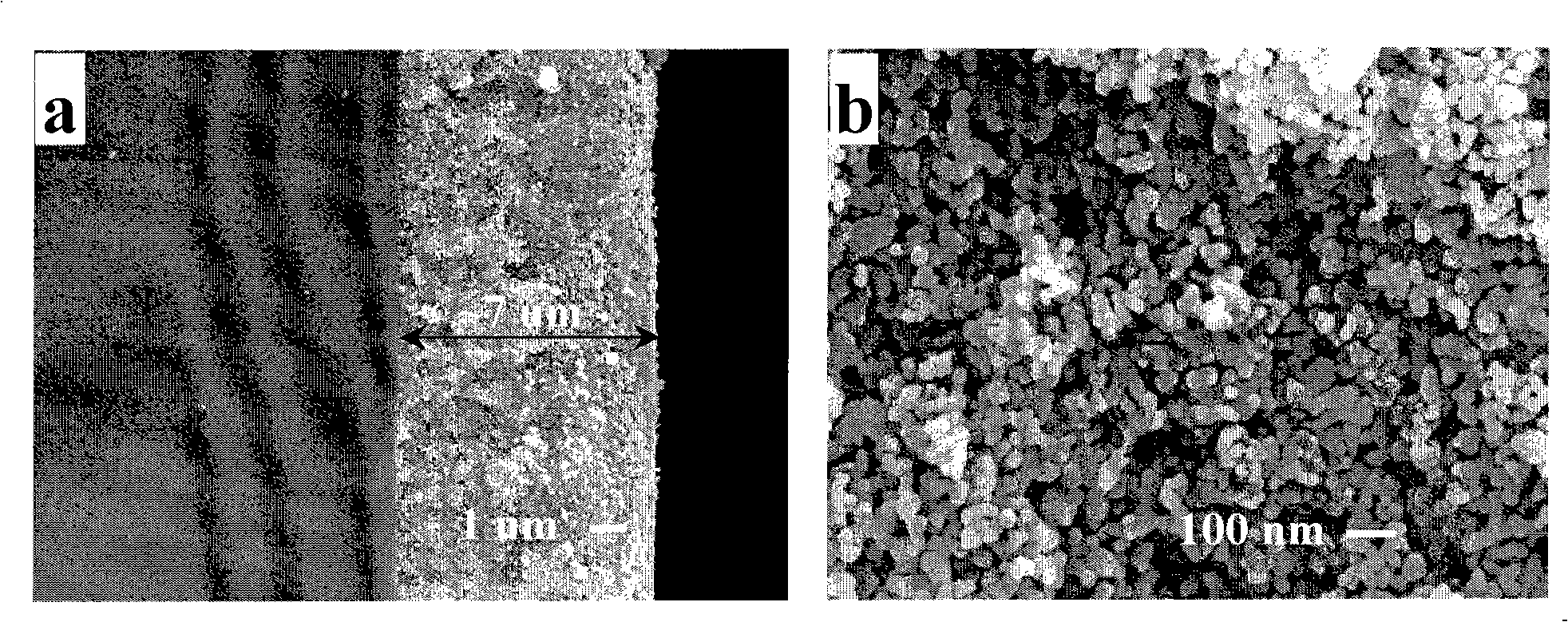

[0076] c. Nanoporous TiO 2 Membrane layer (8): Measure the HNO adsorbed on the surface 3 TiO 2 Mix 0.8 g of nano-powder with 4 ml of water, 0.3 g of polyethylene glycol 10000, and an appropriate amount of surfactant SDS, and grind it in an agate mortar for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com