Resource process method for coking sulfur-containing waste water

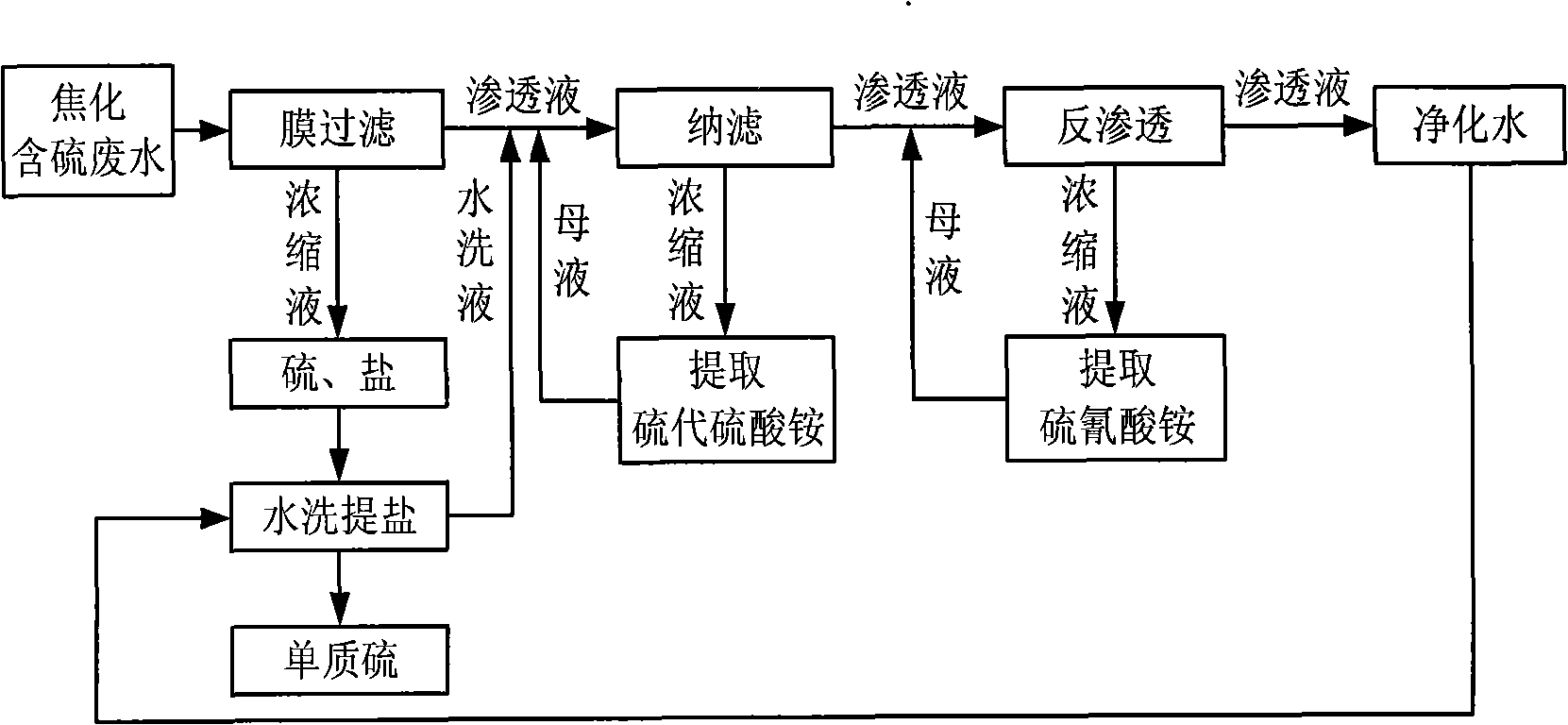

A treatment method and resource-based technology, applied in the field of resource-based treatment of sulfur-containing wastewater from membrane coking, can solve the problems of long removal time of insoluble matter, high content of mother liquor, and low separation efficiency, and achieve remarkable membrane separation effect and excellent operating conditions Easy to control, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The SS of coking sulfur-containing wastewater is 1.6g·L -1 , use 0.8μm zirconia ceramic membrane pretreatment, control operating conditions, temperature 50 ℃, pressure 0.1MPa, membrane surface velocity 3m s -1 , the stable flux is maintained at 1600L m -2 h -1, the permeate liquid does not contain elemental sulfur, and the concentration factor is increased to 80 times. The concentrated elemental sulfur is washed three times and then centrifuged to obtain elemental sulfur with a particle size of 0.1-5 μm; the water washing liquid and the ceramic membrane microfiltration permeate enter together The membrane material is cellulose acetate nanofiltration membrane device for salt separation, the concentration of ammonium thiosulfate is 72.09g L -1 , ammonium thiocyanate concentration 109.05g L -1 , the control pressure is 2.5MPa, the temperature is 48°C, and the permeate volume is 60L·m -2 h -1 , the interception rate of ammonium thiosulfate is 95.6%. When the concentrat...

Embodiment 2

[0031] The SS of coking sulfur-containing wastewater is 20g·L -1 , using 0.22μm organic polymer membrane for pretreatment, the membrane material is polyvinylidene fluoride, the operating conditions are controlled, the temperature is 30°C, the pressure is 0.3MPa, and the membrane surface flow rate is 4m s -1 , the stable flux is maintained at 2000L m -2 h -1 , the permeate supernatant does not contain elemental sulfur, the concentration factor is increased to 50 times, the concentrated elemental sulfur is washed with water three times and then centrifuged, and further purified with chloroform to obtain elemental sulfur with a particle size of 0.5-5 μm. Enter the nanofiltration device for salt separation, the nanofiltration membrane material is polypiperazine amide, and the concentration of ammonium thiosulfate at this time is 68.43g L -1 , ammonium thiocyanate concentration 106.96g L -1 , control pressure 2.0MPa, temperature 30°C, flow rate 650L m -2 h -1 , permeate volume...

Embodiment 3

[0033] The SS of coking sulfur-containing wastewater is 34g·L -1 , using 0.02μm stainless steel metal membrane for concentration treatment, controlled operating conditions, temperature 20°C, pressure 0.05MPa, membrane surface velocity 5m s -1 , the stable flux is maintained at 120L m -2 h -1 , use chloroform, dissolve and saturate, adjust the temperature to precipitate elemental sulfur in the water phase, the particle size is 0.1 ~ 5μm, after the washing liquid is centrifuged, it enters the nanofiltration device together with the permeate for salt separation, and the nanofiltration membrane material is alumina, thiosulfuric acid Ammonium concentration 75.51g·L -1 , ammonium thiocyanate concentration 109.78g L -1 , control pressure 1.0MPa, temperature 48°C, flow 600L m -2 h -1 , permeate volume 15L m -2 h -1 , the interception rate of ammonium thiosulfate is 97.5%, the concentration of ammonium thiosulfate in the concentrated solution is gradually increased to close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com