Method for preparing nano-micro level sun-screening agent with emulsification function

A technology of emulsifying function and sunscreen, which is applied in the direction of cosmetic preparations, skin care preparations, cosmetics, etc., and can solve problems such as slowness, low disassociation rate, and small mobility of chain segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

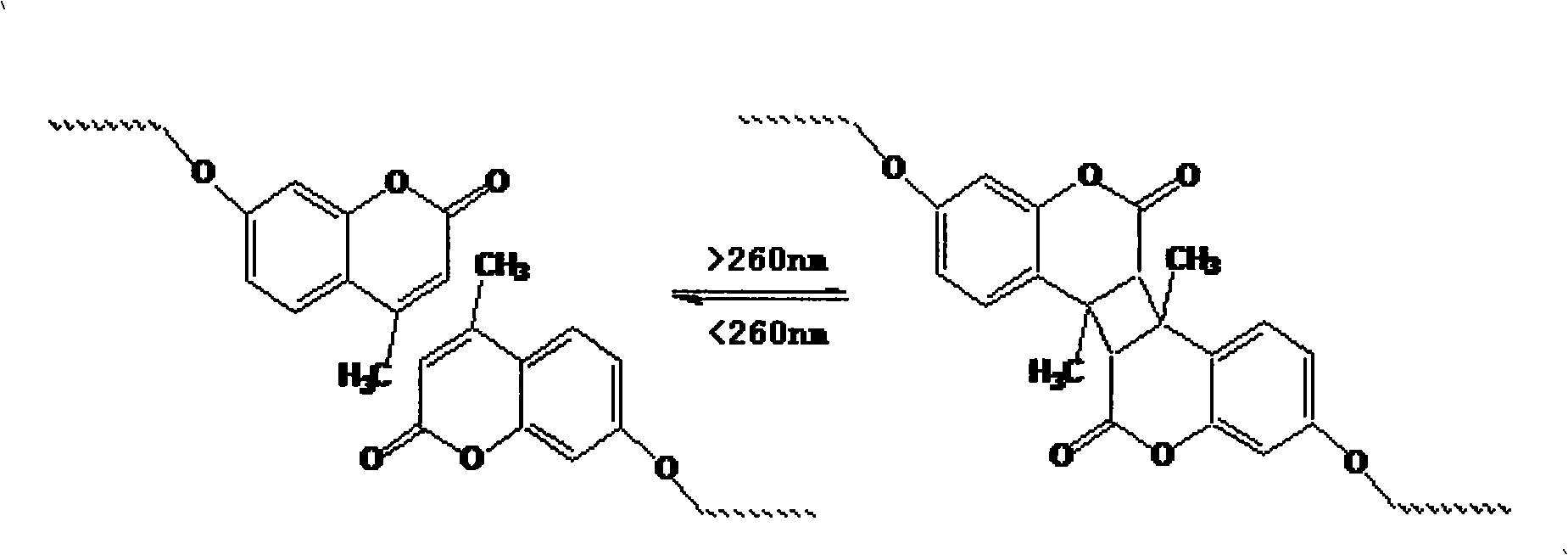

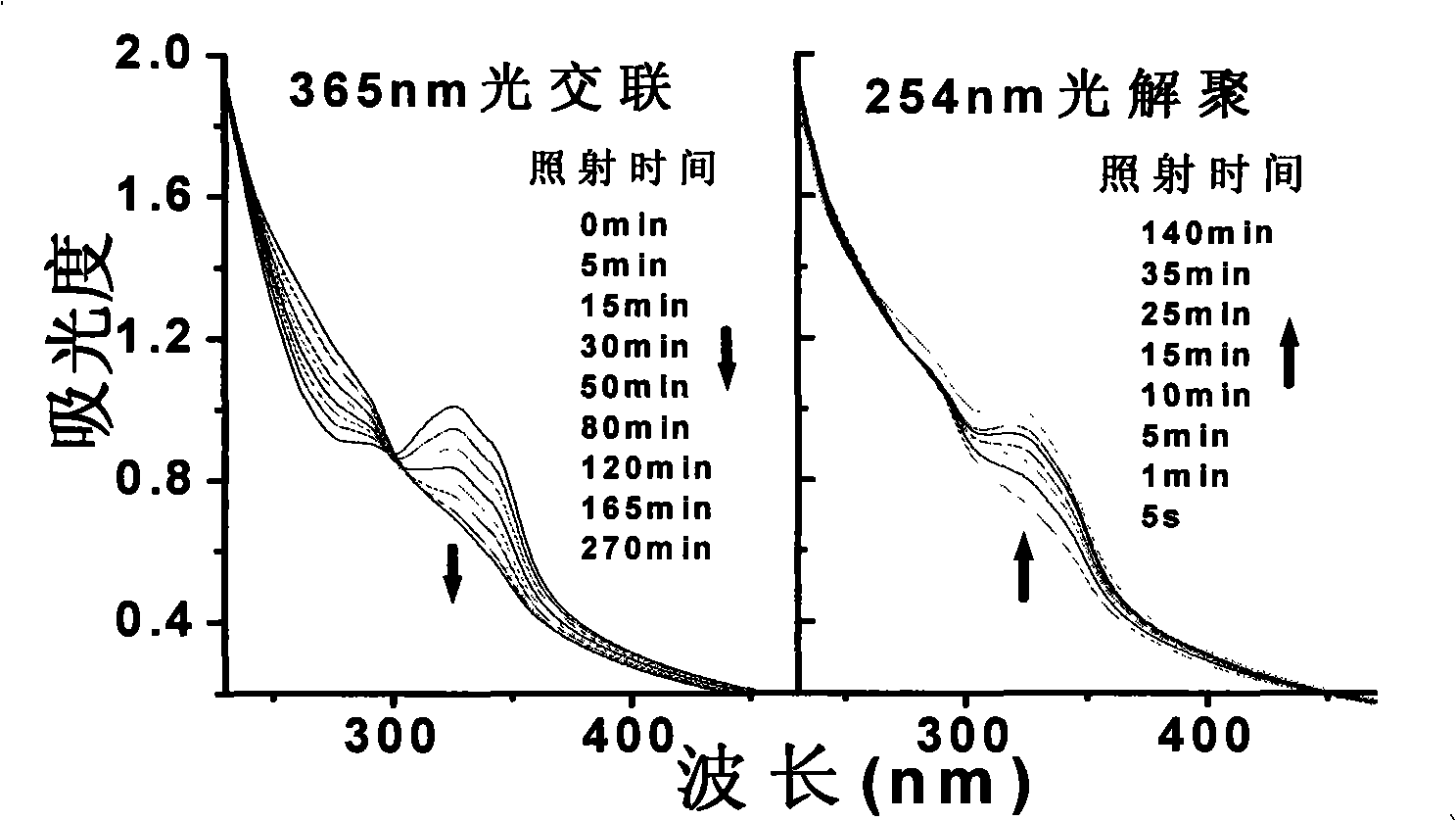

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Dimethylaminoethyl methacrylate, 4-methyl-7-p-vinylbenzylideneoxycoumarin, and methyl methacrylate are fed at one time according to the molar ratio of 15:15:70 , adding 2% of azobisisobutyronitrile to the total molar amount of reactants to initiate, react at 60°C for 24 hours, purify, add lactic acid for neutralization, and obtain a photosensitive amphiphilic copolymer. Dissolve the copolymer in dioxane to form a 5wt% solution, add dropwise ultrapure water until a blue phase appears, continue to stir at a constant speed for 2-12 hours, and remove the dioxane to obtain a pure photosensitive amphiphilic copolymer Micellar aqueous solution, the micellar form is as Figure 4 shown. Place the micellar aqueous solution under a UV lamp with a wavelength of 365nm for 15-300min, and the double bond in coumarin absorbs ultraviolet light to open, and photocrosslinking occurs, and it will re-crosslink under 254nm ultraviolet light for 0.5-120min couplet. Add the polym...

Embodiment 2

[0027] Example 2: N-vinylpyrrolidone and 4-methyl-7-p-vinylbenzylideneoxycoumarin are fed at one time according to the molar ratio of 50:50, and 2% of the total molar amount of reactants is added Initiated by azobisisobutyronitrile, reacted at 80°C for 12 hours, purified, neutralized by adding lactic acid, and vacuum-dried to constant weight to obtain a photosensitive amphiphilic copolymer. Dissolve the copolymer in dioxane to form a 5wt% solution, add dropwise ultrapure water until a blue phase appears, continue to stir at a constant speed for 2-12 hours, and remove the dioxane to obtain a pure photosensitive amphiphilic copolymer Micellar aqueous solution. Place the micellar aqueous solution under a UV lamp with a wavelength of 365nm for 15-300min, and the double bond in coumarin absorbs ultraviolet light to open, and photocrosslinking occurs, and it will re-crosslink under 254nm ultraviolet light for 0.5-120min couplet. Add the polymer micelle solution to the same volume ...

Embodiment 3

[0028] Example 3: Methacryloyloxyethyl trimethyl ammonium chloride, methacryloyloxyethyl cinnamate, and methyl methacrylate are used in a molar ratio of 15:15:70 or 30:30:40 Feed once, start by adding 1% of azobisisobutyronitrile accounting for the total molar amount of reactants, react at 70°C for 20 hours, purify, add lactic acid for neutralization, and vacuum dry to constant weight to obtain a photosensitive amphiphilic copolymer. Dissolve the copolymer in dioxane to form a 5wt% solution, add dropwise ultrapure water until a blue phase appears, continue to stir at a constant speed for 2-12 hours, and remove the dioxane to obtain a pure photosensitive amphiphilic copolymer Micellar aqueous solution. Place the micellar aqueous solution under a UV lamp with a wavelength of 365nm and irradiate it for 15 to 300 minutes. The double bond in the cinnamoyl group absorbs ultraviolet light and opens, photocrosslinking occurs, and then cyclized to form a three-dimensional network struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com