Method for manufacturing erbium-doped hybrid SiO2 optical waveguides amplifier by ultraviolet light direct-writing

An optical waveguide amplifier and a technology for a waveguide amplifier, which are applied in the field of optical communication, can solve the problems of affecting the quality of the waveguide, complicated process, sticking and the like, and achieve the effects of cost saving, simple preparation process and low heat treatment temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

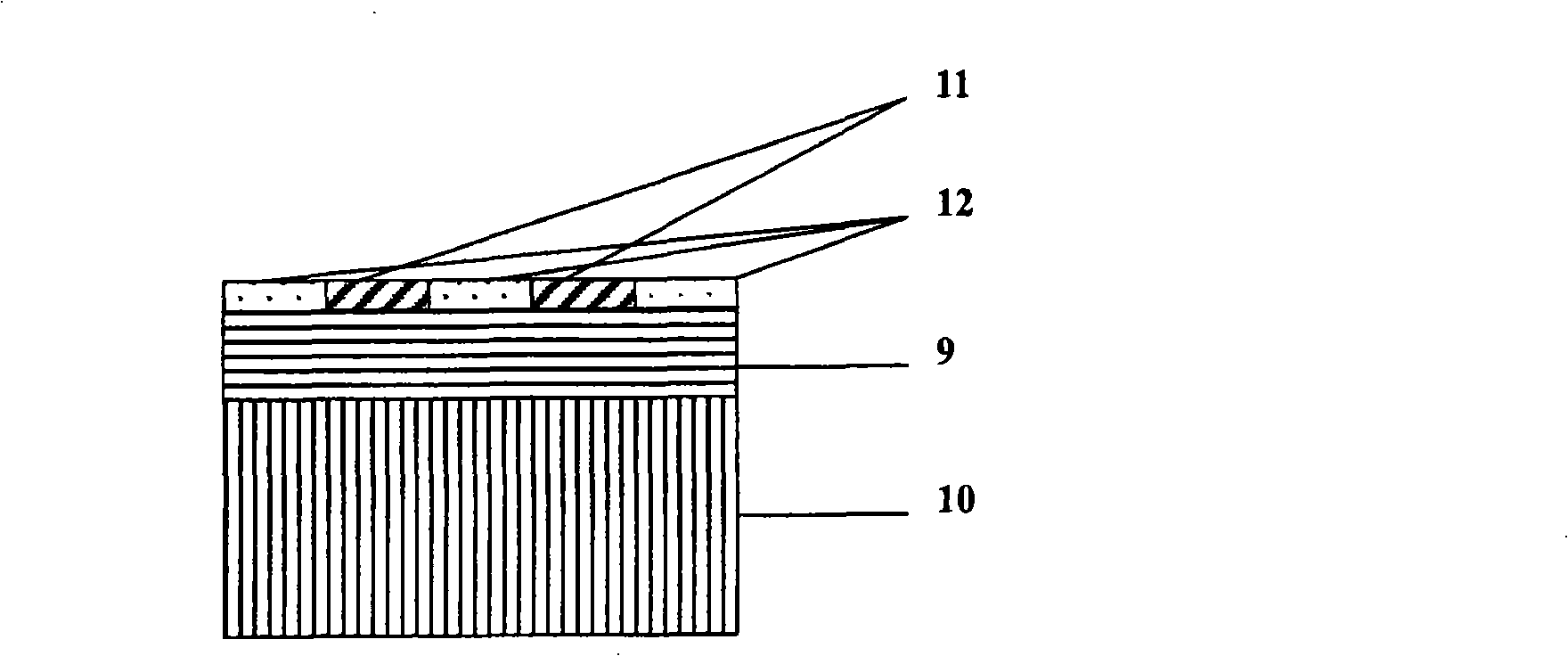

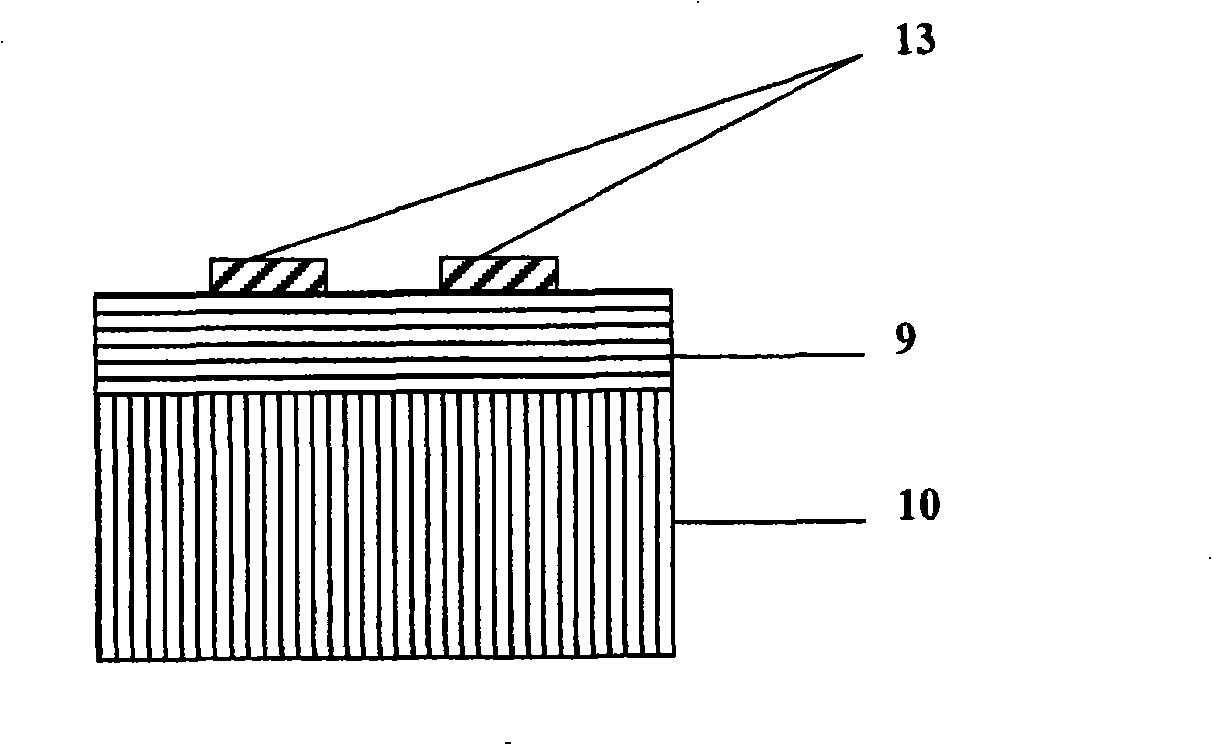

[0026] See Figure 2- Figure 4 Described, a kind of ultraviolet light direct writing of the present invention makes erbium-doped hybrid SiO 2 The method for optical waveguide amplifier, comprises the steps:

[0027] Step 1: first grow the lower cladding layer 9 on the single crystal Si substrate 10 by thermal oxidation method, the thickness of the lower cladding layer 9 is 10 microns-20 microns of SiO 2 ;

[0028] Step 2: Preparation of erbium-doped photosensitive SiO by organic / inorganic hybrid sol-gel method 2 material; the organic / inorganic hybrid erbium-doped photosensitive SiO 2 The preparation of the material is to use methacryloxypropyltrimethoxysilane as the reaction precursor, hydrochloric acid solution as the catalyst, mixing and stirring for hydrolysis, adding zirconium tetrapropoxide to adjust the refractive index, erbium nitrate solution to provide erbium ions, and positive Propanol is used as a solvent, and 1-hydroxy-cyclohexyl benzophenone is added to make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com