Mesoporous calcium silica xerogel for treating skin ulcer and preparation and use thereof

A mesoporous calcium-silicon, skin ulcer technology, applied in skin diseases, pharmaceutical formulations, active ingredients of aluminum/calcium/magnesium, etc. problems, to achieve the effects of pain relief, excellent moisturizing, and sufficient safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

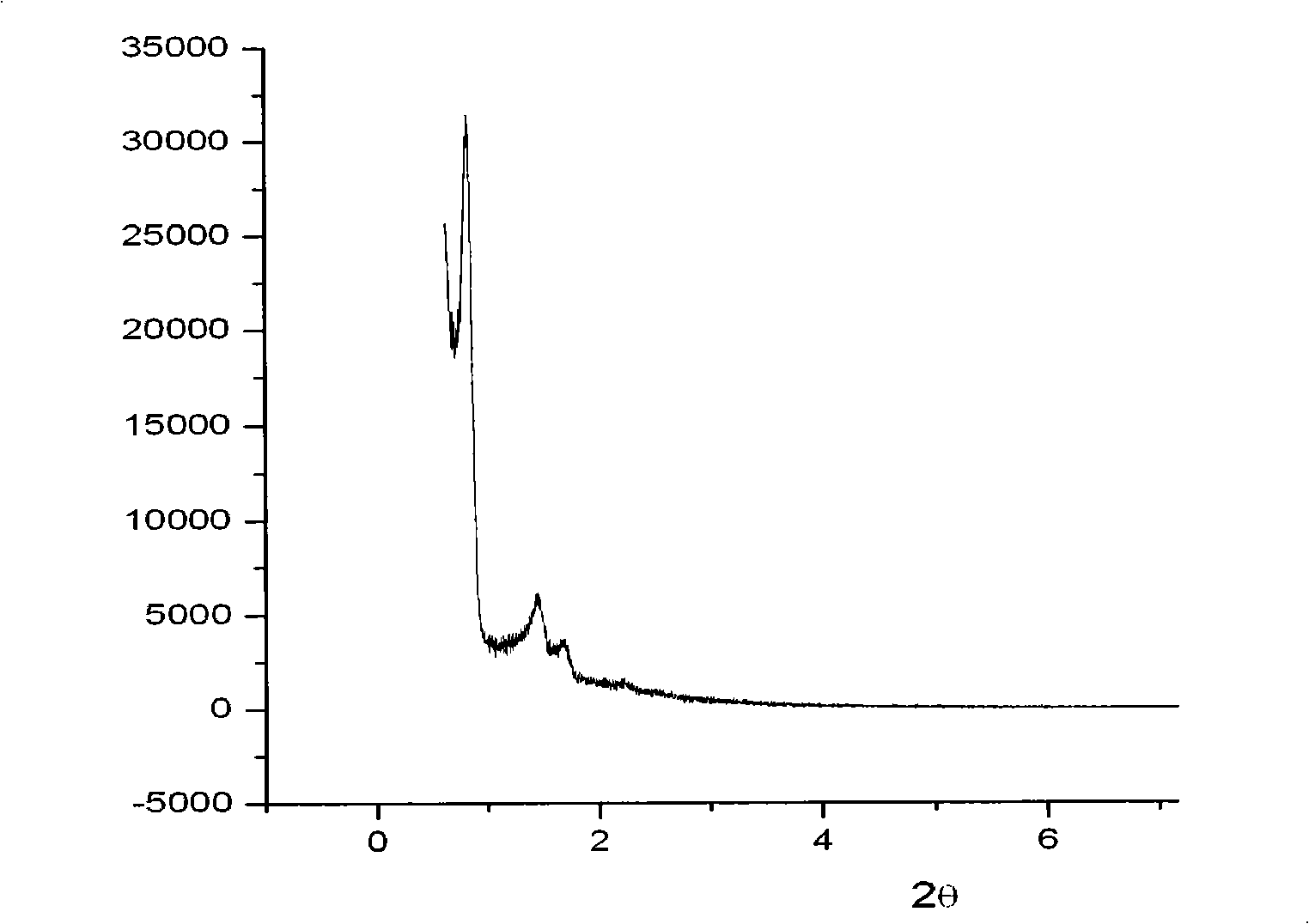

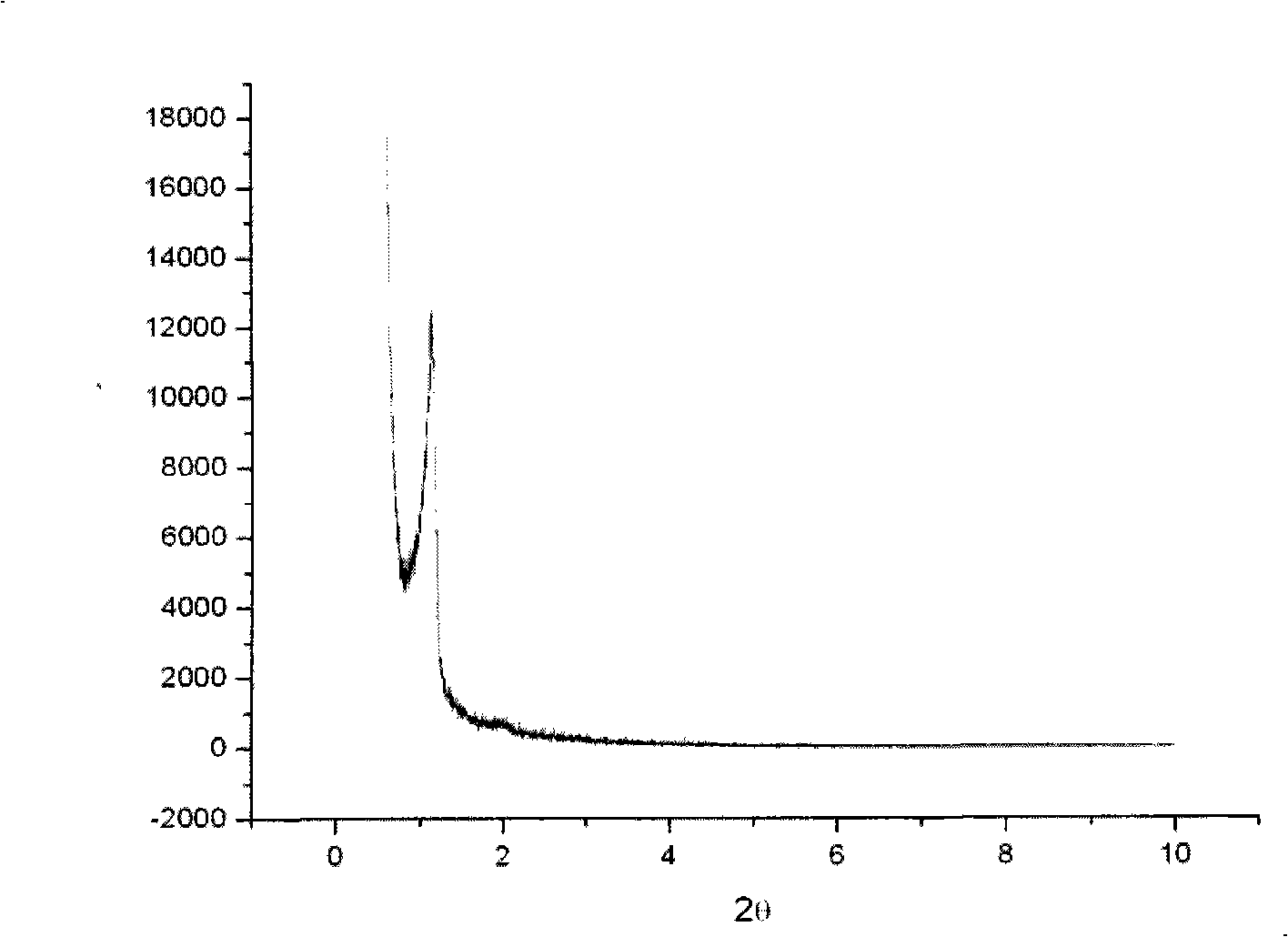

[0058] Add 2g of P123 (polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether triblock copolymer) into ethanol aqueous solution, stir at 40°C for 4 hours, add 4.25 grams of TEOS to the above solution, and then add 80ml 2mol / L hydrochloric acid solution, after stirring for 1h, slowly drop Ca(NO 3 ) 2 Solution (Ca(NO 3 ) 2 2.0 g), after stirring for 24 hours, the solution was transferred to a polytetrafluoroethylene-lined reactor and placed in an oven for crystallization at 110°C for 1 day, and the resulting solution was washed with deionized water, filtered, and dried at room temperature ; Use an air atmosphere on a program temperature-controlled tube furnace to raise the temperature to 500° C. at 1° C. / min, and keep the temperature constant for 6 hours to remove the surfactant. After calcination, cool naturally, pass the powder through a 150-mesh standard sieve, and seal it for later use. The powder is calcium-calcium-silica xerogel (see figure 1 ). The calc...

Embodiment 2

[0060] At room temperature, 1 g of P123 was added to 1 g of absolute ethanol (analytically pure), slowly added dropwise, and after uniform stirring, 2.08 g of tetraethyl orthosilicate (TEOS, analytically pure), 1.71 g of Ca(NO 3 ) 2 and 0.2 gram of hydrochloric acid (1mol / L), and then uniformly stirred for 2 hours, the sol was poured into a polyethylene mold and aged for 2 days, and then dried at 100°C for 12-24 hours. The sample was put into a corundum crucible, heated to 600°C with a program-controlled electric furnace, cooled naturally, ground through a 100-mesh standard sieve, and sealed for later use. The powder is a calcium-silica xerogel containing calcium, denoted as L-2, with a pore size of 3nm and a specific surface of 650m 2 / g, the porosity is 90%, the percentage of the molar weight of silicon oxide to the total molar weight of silicon oxide and calcium oxide is: 80%.

Embodiment 3

[0062] According to TEOS: CaCl 2 :CTAB:NH 3 .H 2 O:H 2 O=1:0.10:0.6:0.47:65 molar ratio, weigh 1g cetyltrimethylammonium bromide (CTAB), dissolve it in ethanol aqueous solution, then add ammonia water, and keep the system at a constant temperature of 35°C Stir for 1 hour to dissolve, slowly add tetraethyl orthosilicate, then CaCl 2 . Stirring was continued for 4-5 hours. Move it into a polytetrafluoroethylene mold to obtain a sol; age the sol at 37° C. for 48 hours, and dry it at 100° C. for 18 hours to obtain a gel. The sample was placed in a muffle furnace at a heating rate of 5°C / min, and baked at 550°C for 6 hours to remove the template. Calcium-containing calcium-silica xerogel material obtained after calcination, with a pore size of 2nm and a specific surface area of 600m 2 / g, the porosity is 80%, the percentage of the molar weight of silicon oxide to the total molar weight of silicon oxide and calcium oxide is: 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com