Method for preparing high dispersibility nano-hydroxyapatite

A nano-hydroxyapatite, high-dispersibility technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of reducing the quality of hydroxyapatite, increasing energy consumption and cost, and expensive equipment. Achieve the effect of regular shape, easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

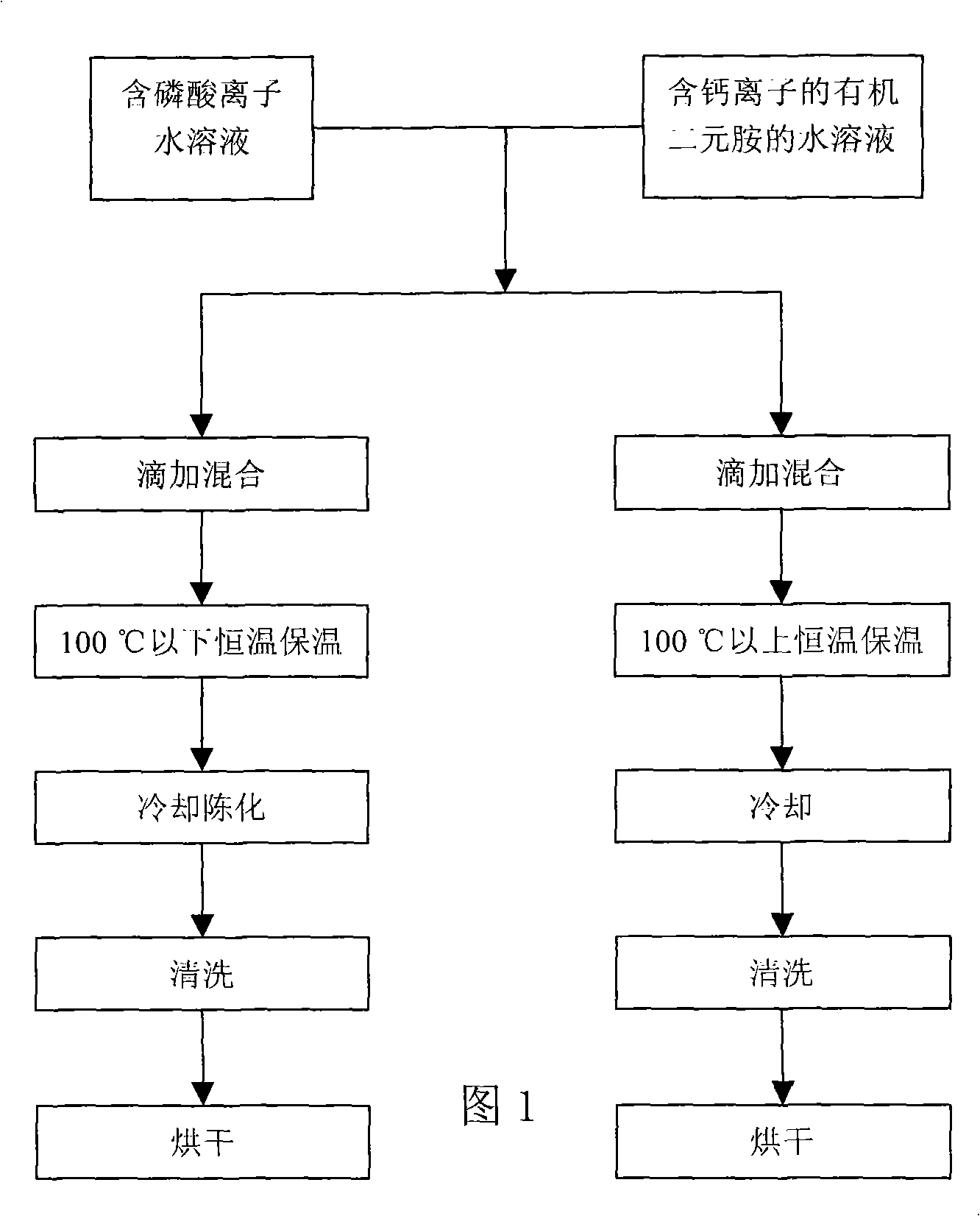

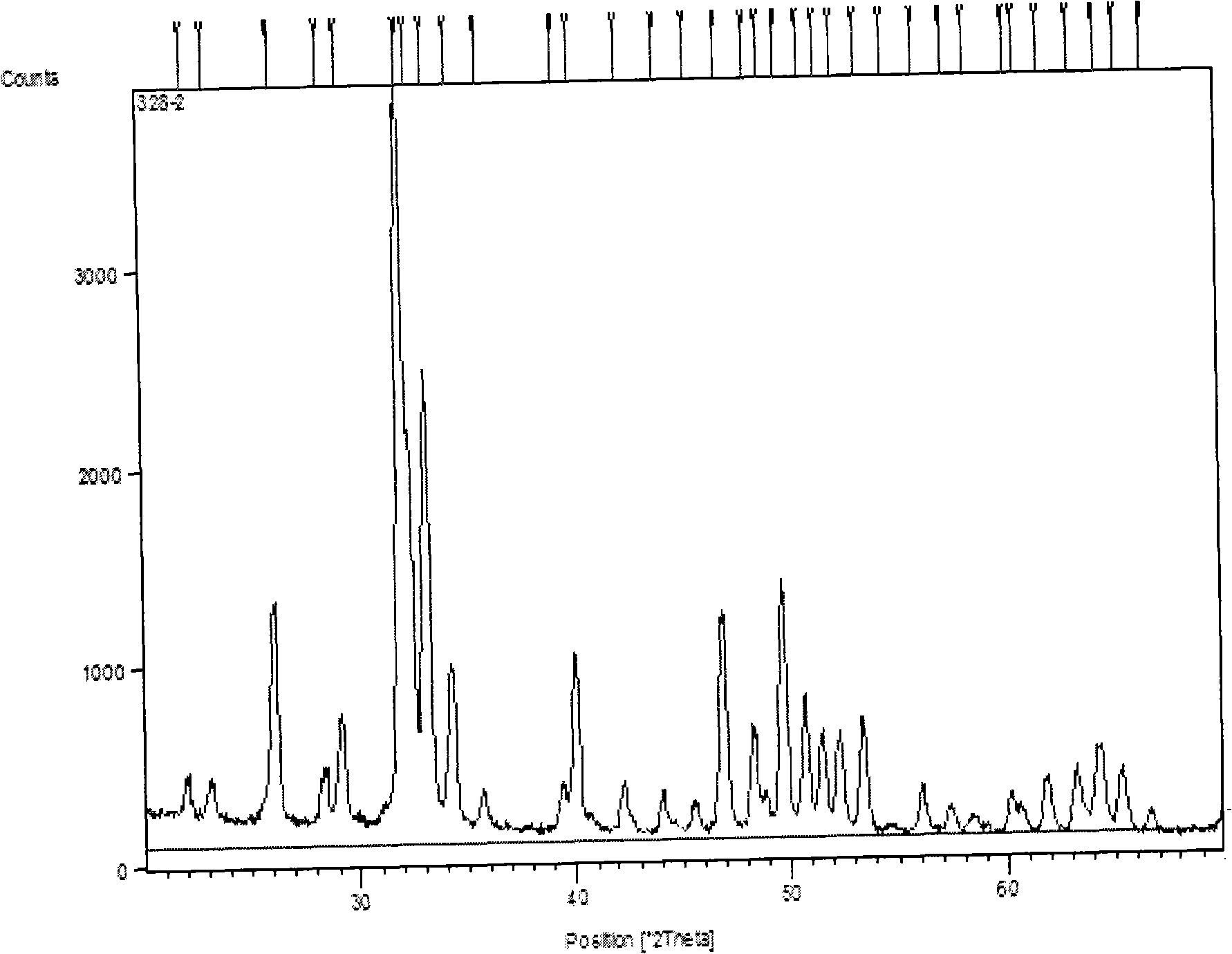

[0011] According to the calcium-phosphorus ratio of 1.67, weigh 9.44g of calcium nitrate tetrahydrate, dissolve in 20ml of water, add 10ml of ethylenediamine, heat to 60°C, and stir until the calcium nitrate is completely dissolved; weigh 1.7g of phosphorus pentoxide, dissolve in 10ml of water, stir until phosphorus pentoxide is completely dissolved. Stir the phosphorus pentoxide solution, slowly drop the calcium nitrate solution into the phosphorus pentoxide solution, and continue stirring after the dropwise addition is completed. Pour the mixed solution into a Teflon beaker liner with a total volume of 50ml, put it into a stainless steel autoclave, heat it to 180°C, keep it warm for 24 hours, and cool it at room temperature after the heat preservation is over. Ethanol was used as a lotion, and the centrifugal washing was performed several times until the product was washed neutral. The product was dried in a drying cabinet at 60°C. Thus obtained highly dispersed hydroxyapa...

Embodiment 2

[0014] Weigh 9.44g of calcium nitrate tetrahydrate, dissolve in 90ml of water, add 30ml of ethylenediamine, stir until clarified; weigh 1.7g of phosphorus pentoxide, dissolve in 80ml of water, put into a water bath or Heat to 90°C in a constant temperature heating mantle. Slowly drop the calcium nitrate solution into the phosphorus pentoxide solution at a constant temperature of 90°C under vigorous stirring, a white precipitate is produced, and continue to stir after the dropwise addition is completed. Then, the mixed solution after the dropwise addition was continued to be kept at 90° C. for 2 h. After the heat preservation, it was cooled at room temperature and aged for 1 day. The cleaning and drying process is the same as in Example 1, and nano-hydroxyapatite with finer grains is obtained.

Embodiment 3

[0016] Weigh 9.44g of calcium nitrate tetrahydrate, dissolve it in 20ml of water, add 10ml of ethylenediamine, heat to 60°C to increase the solubility, and stir until clarification; weigh 3.1616g of diammonium hydrogen phosphate and dissolve it in 10ml of water according to the calcium-phosphorus ratio of 1.67 , stirred to a clear solution, and the rest of the process was the same as in Example 1 to obtain highly dispersed nano-hydroxyapatite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com