Surface modified barium sulfate base ultrafine function powder material and preparation method thereof

A surface modification and functional powder technology, applied in fibrous fillers and other directions, can solve the problems of inability to meet downstream applications, poor functionality, and large equipment, achieving excellent industrial value, excellent surface properties, and increasing functionality and phase. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

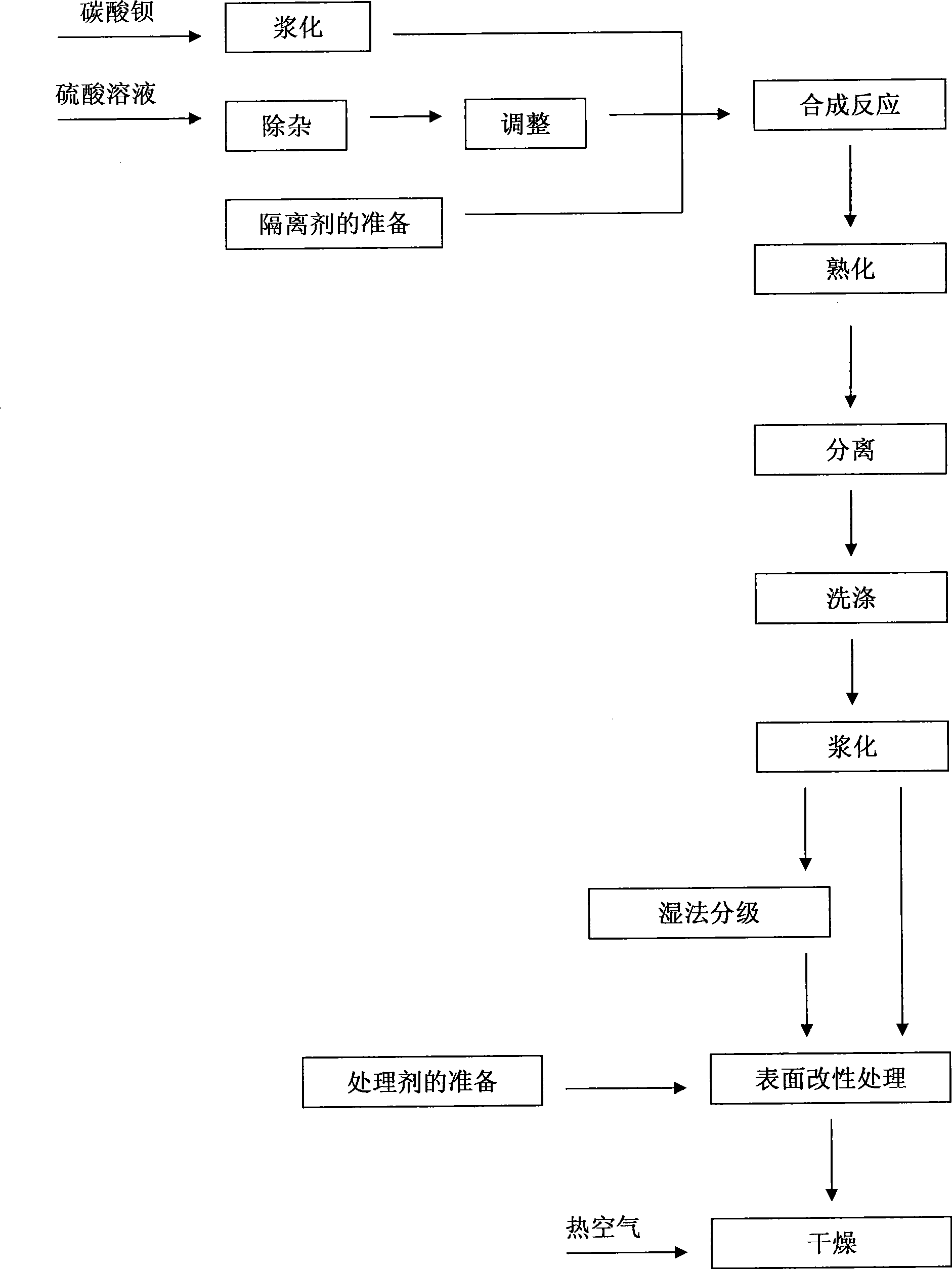

[0022] A surface-modified barium sulfate-based ultra-fine functional powder material used in the production of plastics. The powder material is prepared from a suspension of barium sulfate powder and treated with a treatment agent sodium stearate for surface modification. The maximum particle size of the barium sulfate powder of the matrix is below 2 μm, and the particle size (D50) is below 0.5 μm. The powder material is mainly used for polyethylene (PE plastic), polypropylene (PP plastic), acrylonitrile-butylene Diene-styrene copolymer (ABS plastic) is reinforced to enhance its weather resistance, increase gloss and reduce costs. The powder material has surface hydrophobic properties and excellent compatibility, and it is mainly prepared by the following method (such as figure 1 process shown):

[0023] (1) The preparation of raw material: first raw material barium carbonate is carried out slurrying, the mass concentration after slurrying is controlled at 30%; Sulfuric aci...

Embodiment 2

[0029]A surface-modified barium sulfate-based ultrafine functional powder material for producing printing ink, the powder material is made of barium sulfate powder suspension through a mixture of ethylenediaminetetraacetic acid and triethanolamine (mass ratio is 1: 3) Prepared after surface modification treatment, the maximum particle size of the barium sulfate powder used as the matrix is below 1 μm, and the particle size (D50) is below 0.3 μm. This powder material can greatly improve the brightness and color of high-end inks Realistic, weather-resistant and impermeable, and enables ultra-thin coatings. The surface of the powder material has amphoteric groups, which are mainly prepared by the following methods:

[0030] (1) The preparation of raw material: first raw material barium carbonate is carried out slurrying, the mass concentration after slurrying is controlled at 22%; Sulfuric acid solution is removed impurity, adjusts sulfuric acid solution mass concentration valu...

Embodiment 3

[0036] A surface-modified barium sulfate-based ultrafine functional powder material for rubber production. The powder material is prepared from barium sulfate powder suspension through surface modification treatment with siloxane. Barium sulfate as a matrix The maximum particle size of the powder is below 1 μm, and the particle size (D50) is below 0.5 μm. The powder material is mainly prepared by the following methods:

[0037] (1) The preparation of raw material: first raw material barium carbonate is carried out slurrying, the mass concentration after slurrying is controlled at 26%; Sulfuric acid solution is removed impurity, adjusts sulfuric acid solution mass concentration value to be 85%; Prepare a certain amount (its quality 2% of the quality of barium carbonate) isolating agent sodium metasilicate;

[0038] (2) Synthetic reaction: the above-mentioned prepared release agent sodium metasilicate is formulated into a solution (mass concentration is 3%) and added in the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com