Preparation method and use of visible light responsive nitrogen-doped titanium dioxide nano-tube

A titanium dioxide, nanotube technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as tubular structure damage, achieve complete tubular structure, excellent stability and visible light response performance, The effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

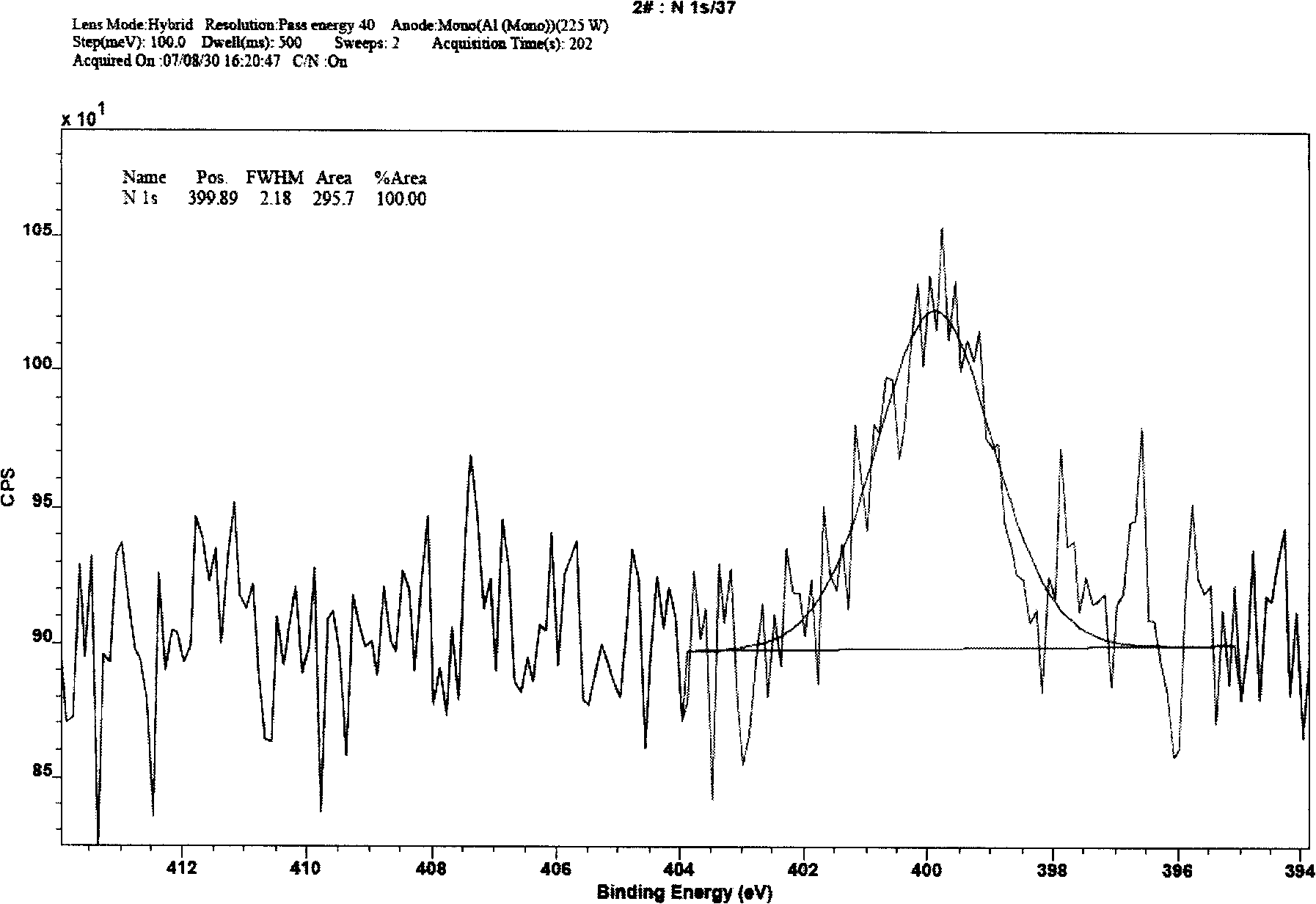

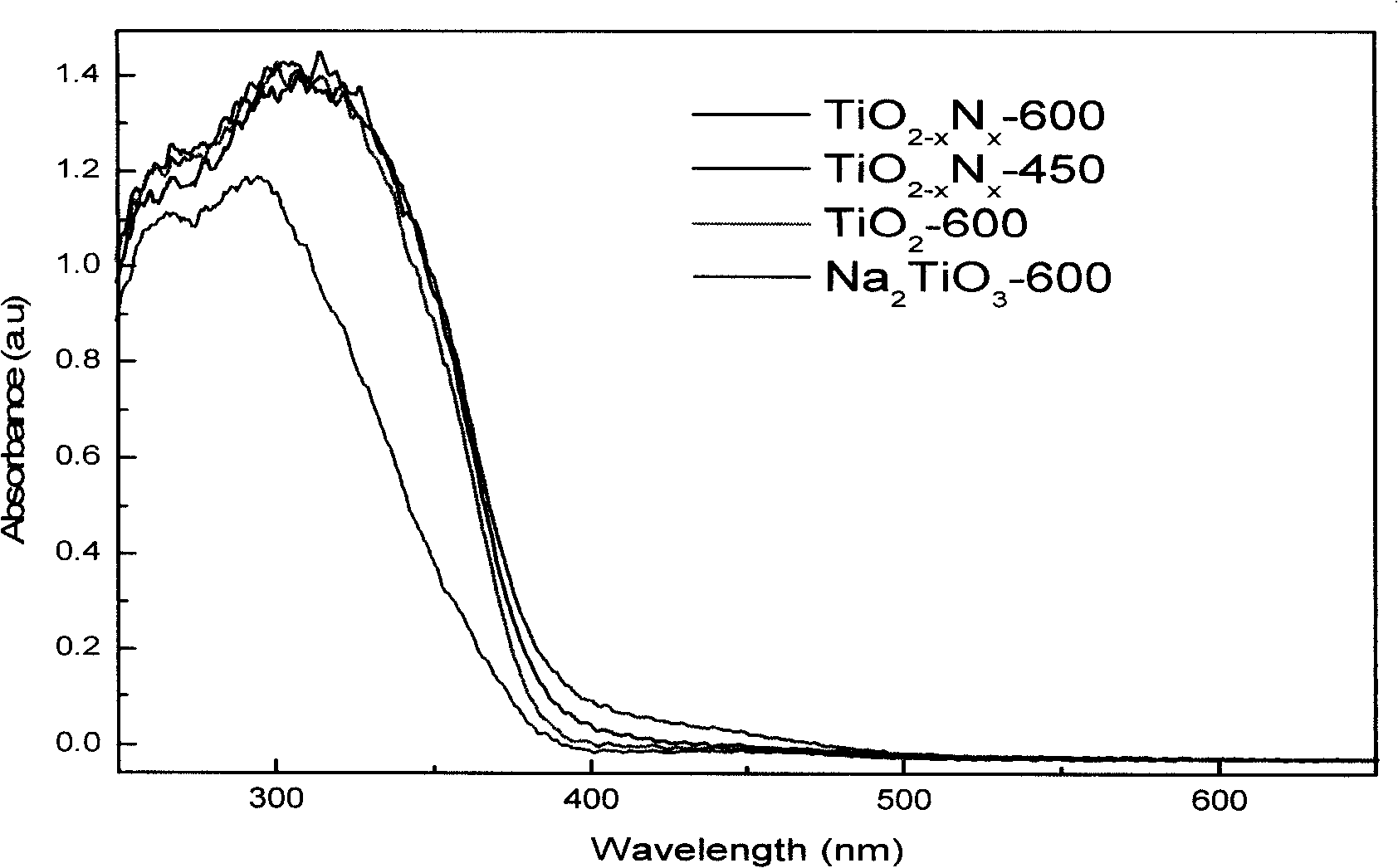

Embodiment 1

[0032] Weigh 3.2 grams of commercial anatase TiO 2 , added to 75mL of 10M NaOH solution, stirred vigorously for 30 minutes, then transferred to a 100mL Teflon-lined autoclave, and treated at 160°C for 24 hours, the resulting white precipitate was washed with deionized water Wash with 0.2M hydrochloric acid to neutralize, and obtain metatitanic acid nanotubes. The newly prepared metatitanic acid nanotubes were dispersed in ammonia water, ultrasonically treated for 20 minutes, then moved into a 100mL Teflon-lined autoclave with a filling degree of 80%, treated at 120°C for 12 hours, and the product was taken out After suction filtration and water washing, the obtained white precipitate was dried at 60°C, then dried at 120°C, and finally roasted at 250-600°C for 2 hours to obtain a series of light yellow TiO 2-X N X nanotube product. XRD (X-ray), FESEM (Field Emission Scanning Electron Microscope) and TEM (Transmission Electron Microscope) showed that it was anatase phase TiO ...

Embodiment 2

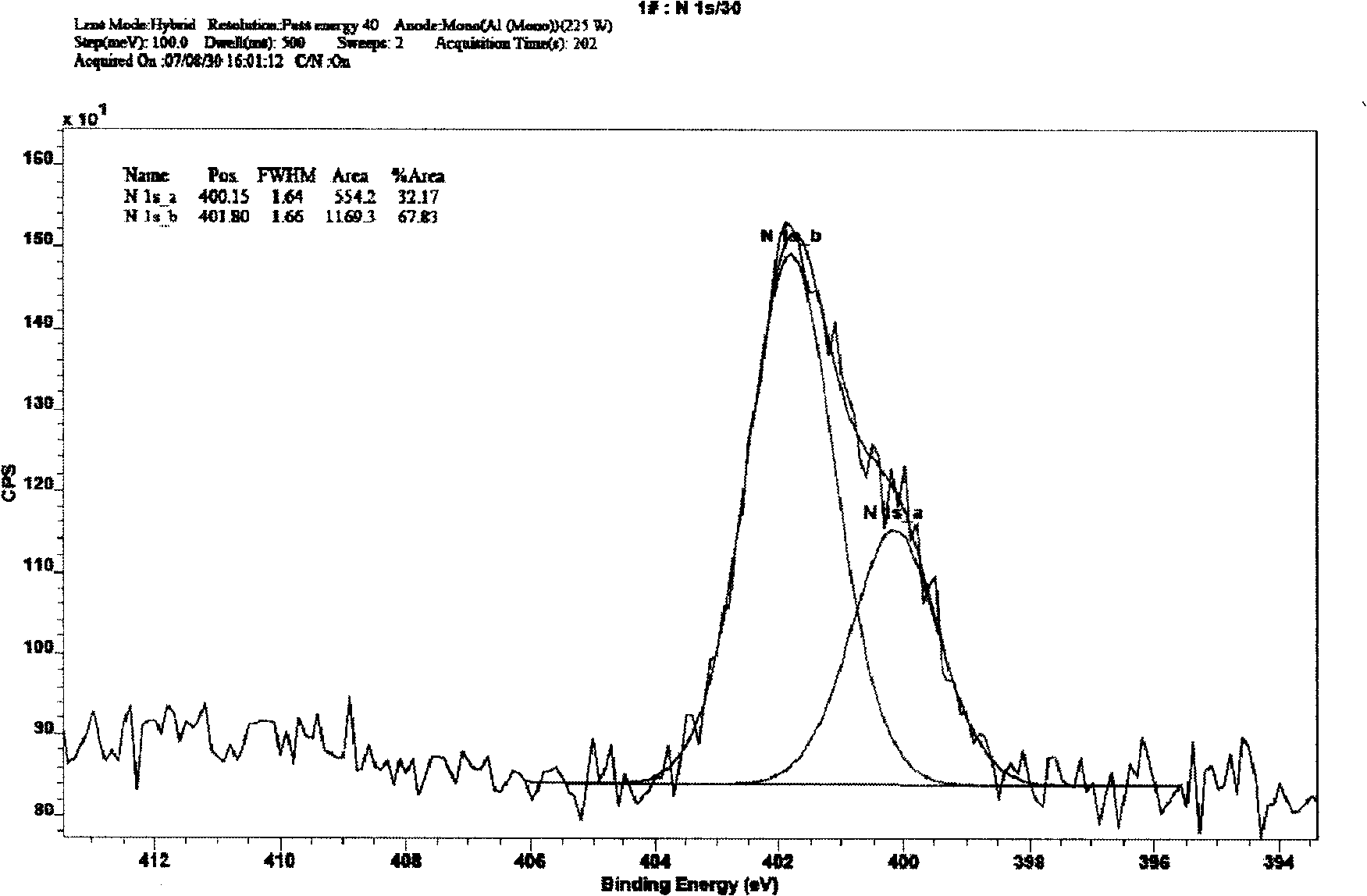

[0035] Weigh 3.2 grams of commercial anatase TiO 2 , added to 75mL of 10M NaOH solution, stirred vigorously for 30 minutes, then transferred to a 100mL Teflon-lined autoclave, and treated at 160°C for 24 hours, the resulting white precipitate was washed with deionized water Wash with 0.2M hydrochloric acid to neutralize, and obtain metatitanic acid nanotubes. Disperse the new metatitanic acid nanotubes in the water / alcohol mixed solution of 20% ammonium chloride by weight fraction, stir for 7 hours, move into the autoclave of the polytetrafluoroethylene lining of 100mL volume, and the filling degree is 80%, treated at 120°C for 3 hours, a yellow precipitate was obtained, the product was taken out, filtered, washed with water, dried at 60°C, and then dried at 120°C to obtain a series of light yellow TiO 2-X N X nanotube product. XRD, FESEM and TEM showed that it was anatase phase TiO 2-X N X nanotube. The nanotubes can be further roasted at 250-1000°C under an inert atmos...

Embodiment 3

[0038] Weigh 4 grams of commercial metatitanic acid nanotubes, disperse them in hydrazine hydrate, stir for 4 hours, move into a 100mL Teflon-lined autoclave with a filling degree of 80%, and treat them at 120°C for 12 hours, the product After being taken out, filtered and washed with water, the obtained white precipitate was dried at 60°C, then dried at 120°C, and finally roasted at 250-450°C for 2 hours to obtain a series of light yellow TiO 2-X N X nanotube product. XRD, FESEM and TEM showed that it was anatase phase TiO 2-X N X nanotube. Among them, the specific surface area of the sample calcined at 250°C for 2 hours is 300m 2 / g, the specific surface area of the sample calcined at 450°C for 2 hours is 140m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com