Water purification method for circulating water industrialized aquiculture system and complex bacterial agent thereof

A compound bacterial agent and aquaculture technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Lack of pertinence in functions, increase system operating costs and other issues, to achieve the effect of ensuring water quality, stabilizing pH value, and reducing the content of water pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

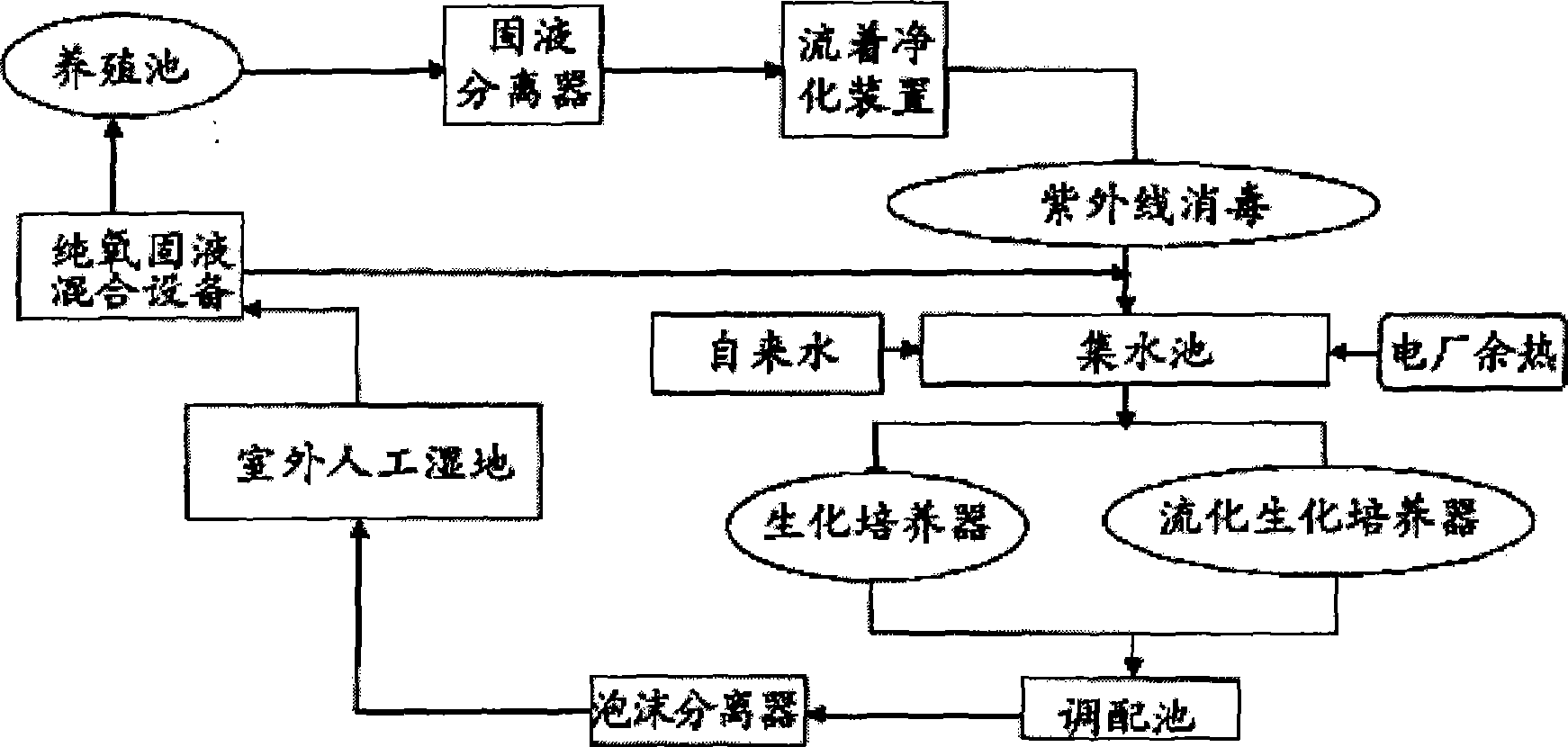

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, the water quality purification method of circulating water factory aquaculture system and its composite bacterial agent.

[0045] Preparation of Special Bacteria Agent for Purification of Circulating Water

[0046] Bacillus, lactic acid bacteria, photosynthetic bacteria, nitrifying bacteria, pseudomonas, paracoccus and alcaligenes strains are purchased from the market or obtained from relevant microorganism depository institutions or other channels, and the slant is carried out on the corresponding medium as usual Activation culture and liquid expansion culture.

[0047] The slant activation medium used has Nitrobacteria solid medium (for cultivating Nitrosomonas bacteria), Nitrobacter solid medium (for cultivating Nitrobacter and Nitrospira bacteria), nutrient agar medium (for cultivating Bacillus , Pseudomonas, Paracoccus and Alcaligenes), RCVBN solid medium (for cultivating photosynthetic bacteria), MRS solid medium (for cultivating lactic acid bacteri...

Embodiment 2

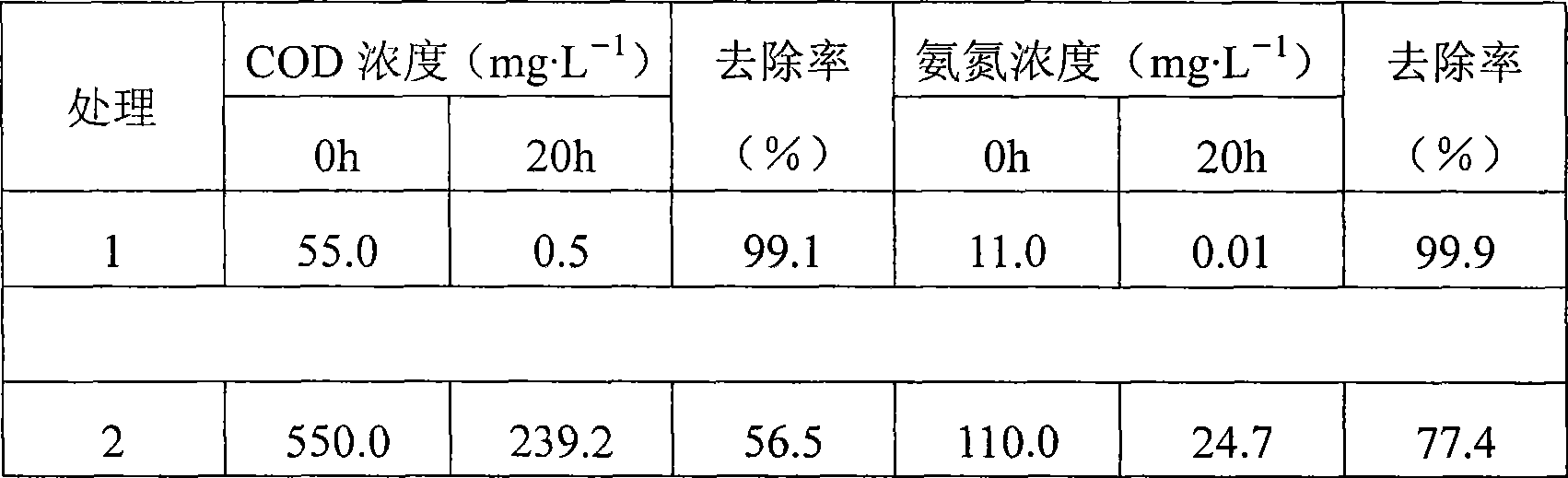

[0064] Embodiment 2, the purifying effect of special bacteria agent for water quality purification to simulated aquaculture wastewater

[0065] Take compound bacterial agent I 30%

[0066] Compound Bacteria II 40%

[0067] Compound Bacteria III 30%

[0068] The proportion of water purification special compound bacterial agent.

[0069] Soak the commercially available extruded feed produced by a certain company in water for 2 hours, remove the residue, dilute, and configure the COD to be 550mg·L -1 , the concentration of ammonia nitrogen is 110mg·L -1 and COD is 55mg·L -1 , the concentration of ammonia nitrogen is 11mg·L -1 The two kinds of simulated aquaculture wastewater were added with 5% inoculation amount of special compound bacterial agent for water purification, and the purification experiment of simulated aquaculture wastewater was carried out under the condition of 25°C shaker culture, and the concentration of COD and ammonia nitrogen in the water was measured aft...

Embodiment 3

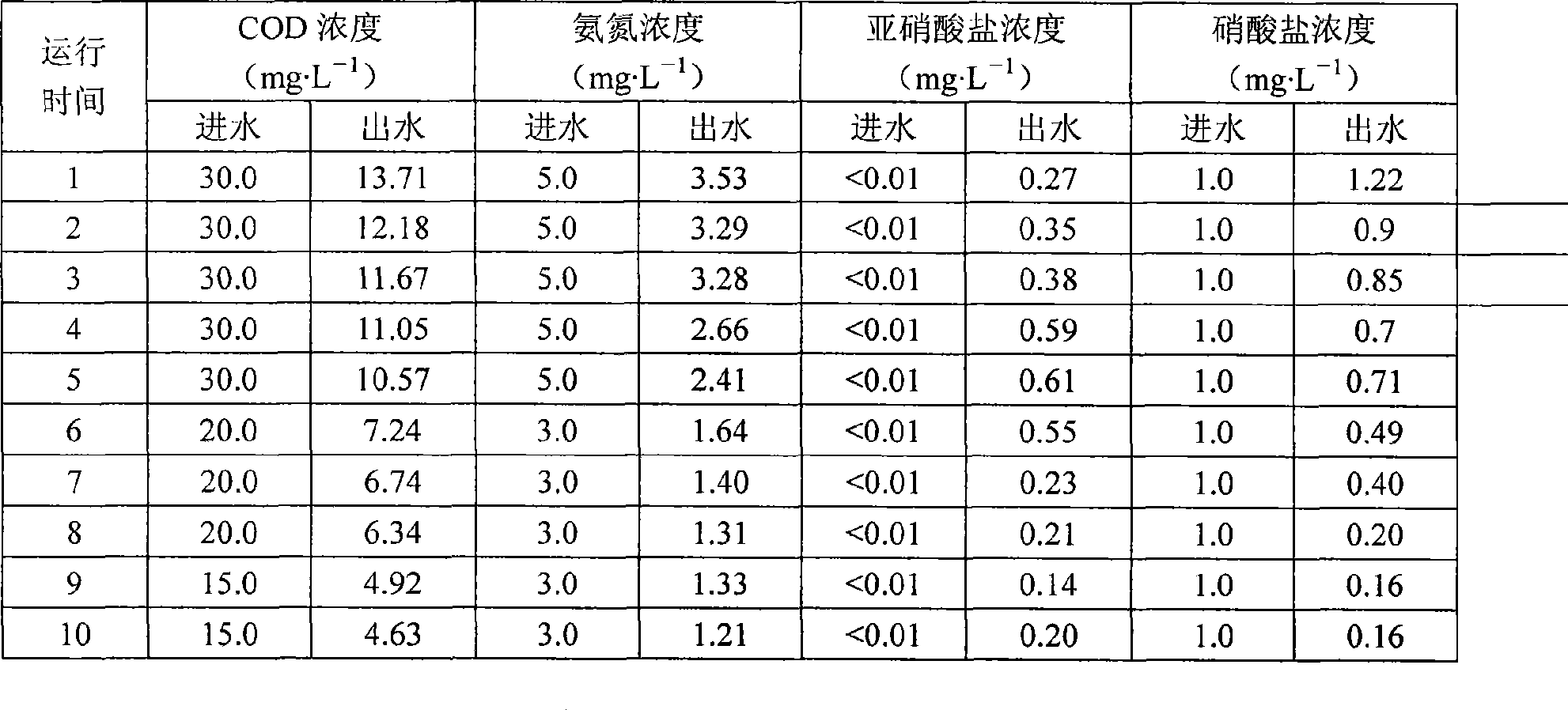

[0072] Embodiment 3, the purifying effect of special bacteria agent for water quality purification in simulation system

[0073] Take compound bacterial agent I 30%

[0074] Compound Bacteria II 30%

[0075] Compound Bacteria III 40%

[0076] The proportion of water purification special compound bacterial agent.

[0077] This experiment is carried out in a small circulation simulation system consisting of a biological filter and a sump, and the total volume of the water body is 2m 3 . The biological filter filler is PVC pellets, and artificial aquatic plants are placed in the sump.

[0078] The purification compound bacteria agent is used to directly hang the film, and the dosage of the compound bacteria agent is 1% of the total volume of the system water body. Add the composite bacterial agent I to the sump, add the composite bacterial agent II and the composite bacterial agent III to the biochemical reactor, and expose for 2 weeks, so that the bacterial agent is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com