Microporous membrane, battery separator and battery

A technology of battery separator and microporous membrane, which is applied in secondary batteries, battery pack parts, non-aqueous electrolyte storage batteries, etc., can solve the problems of non-closing properties and needle penetration strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] (1) Preparation of the first polyolefin solution

[0057] Polyethylene is combined with a diluent (eg, by melt blending) to produce a first polyolefin solution. The first polyolefin solution in some embodiments may include various additives, such as antioxidants, UV absorbers, antiblocking agents, pigments, dyes, inorganic fillers, if desired. For example, fine silicate powder may be added as a pore former.

[0058] Optionally, the diluent is liquid at room temperature, ie it can be a liquid solvent. The use of liquid solvents enables relatively high-magnification stretching. The liquid solvent may be an aliphatic or cycloaliphatic hydrocarbon such as nonane, decane, decahydronaphthalene, p-xylene, undecane, dodecane, liquid paraffin, distillation of mineral oil with a boiling point comparable to that of the above hydrocarbons phthalate liquids at room temperature (e.g. dibutyl phthalate, dioctyl phthalate), mixtures thereof and mixtures of liquid paraffin. In order...

Embodiment 1

[0137] (1) Preparation of the first microporous polyolefin membrane

[0138] 100 parts by mass of a polyethylene (PE) composition and 0.05 parts by mass of tetrakis[methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate] as an antioxidant Methane is dry blended, and the polyethylene (PE) composition comprises 18% by mass of a weight average molecular weight (Mw) of 2.5×10 6 of ultra-high molecular weight polyethylene (UHMWPE) and 82% by mass with a Mw of 3.0×10 5 high-density polyethylene (HDPE). Measurements show that the polyethylene composition of UHMWPE and HDPE has a melting point of 135°C and a crystallization dispersion temperature of 90°C.

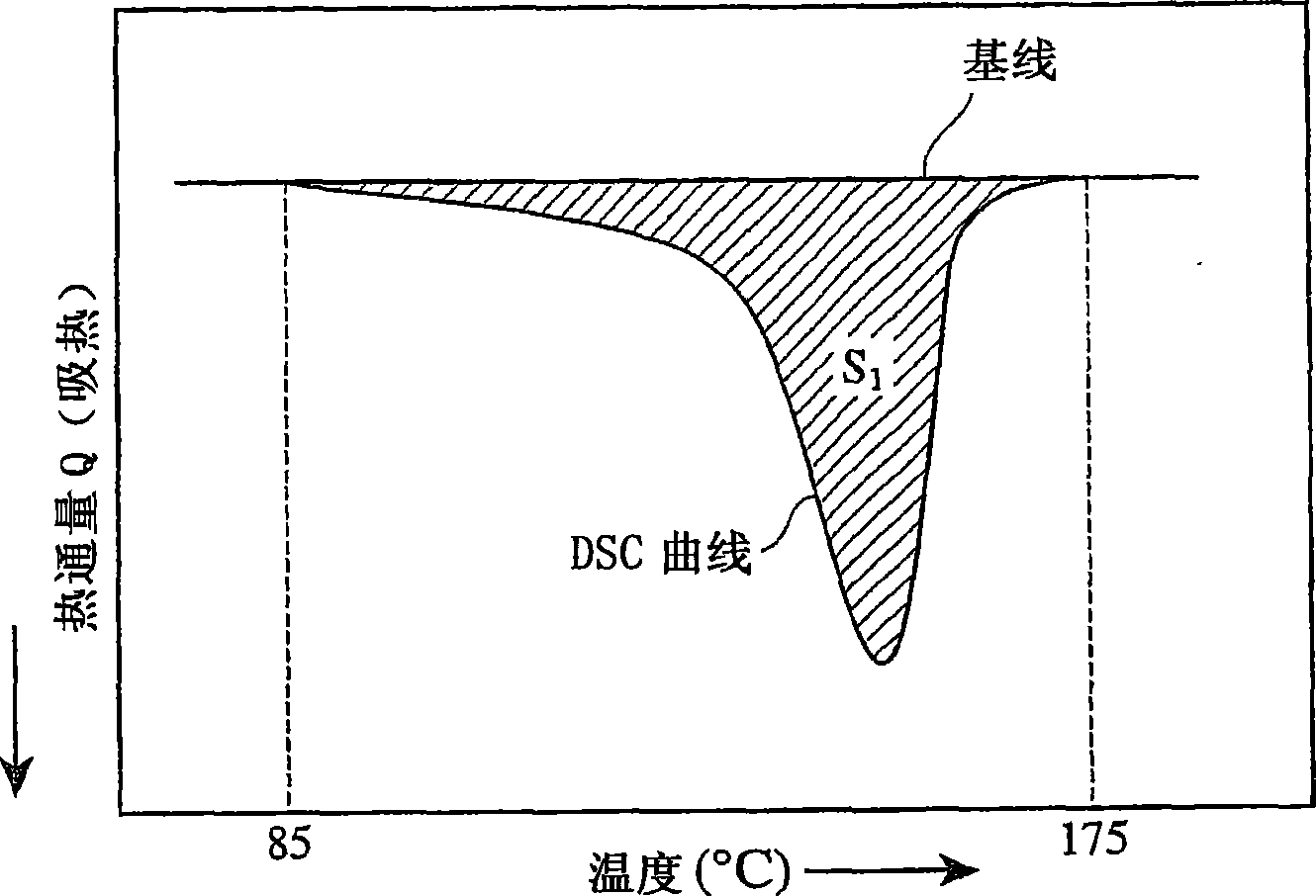

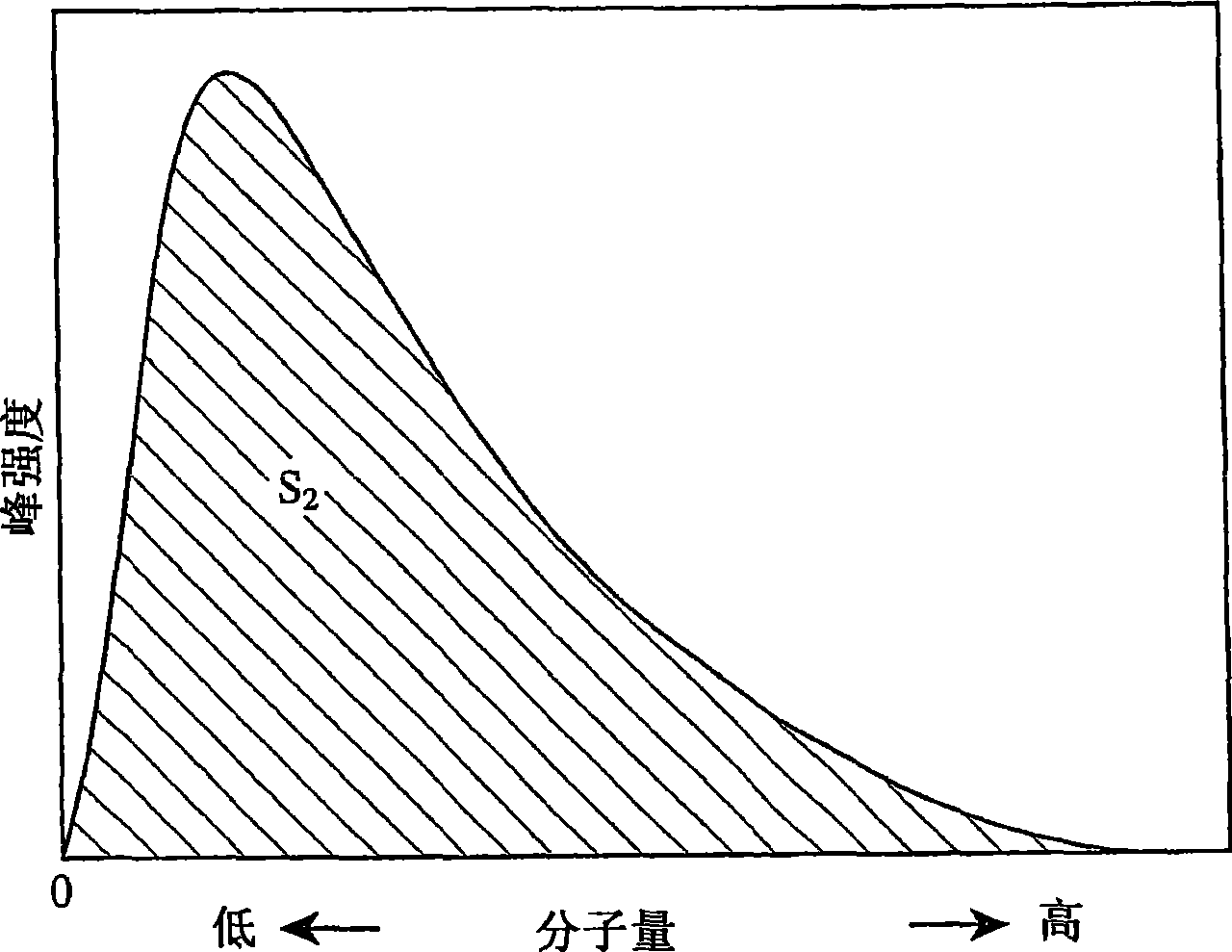

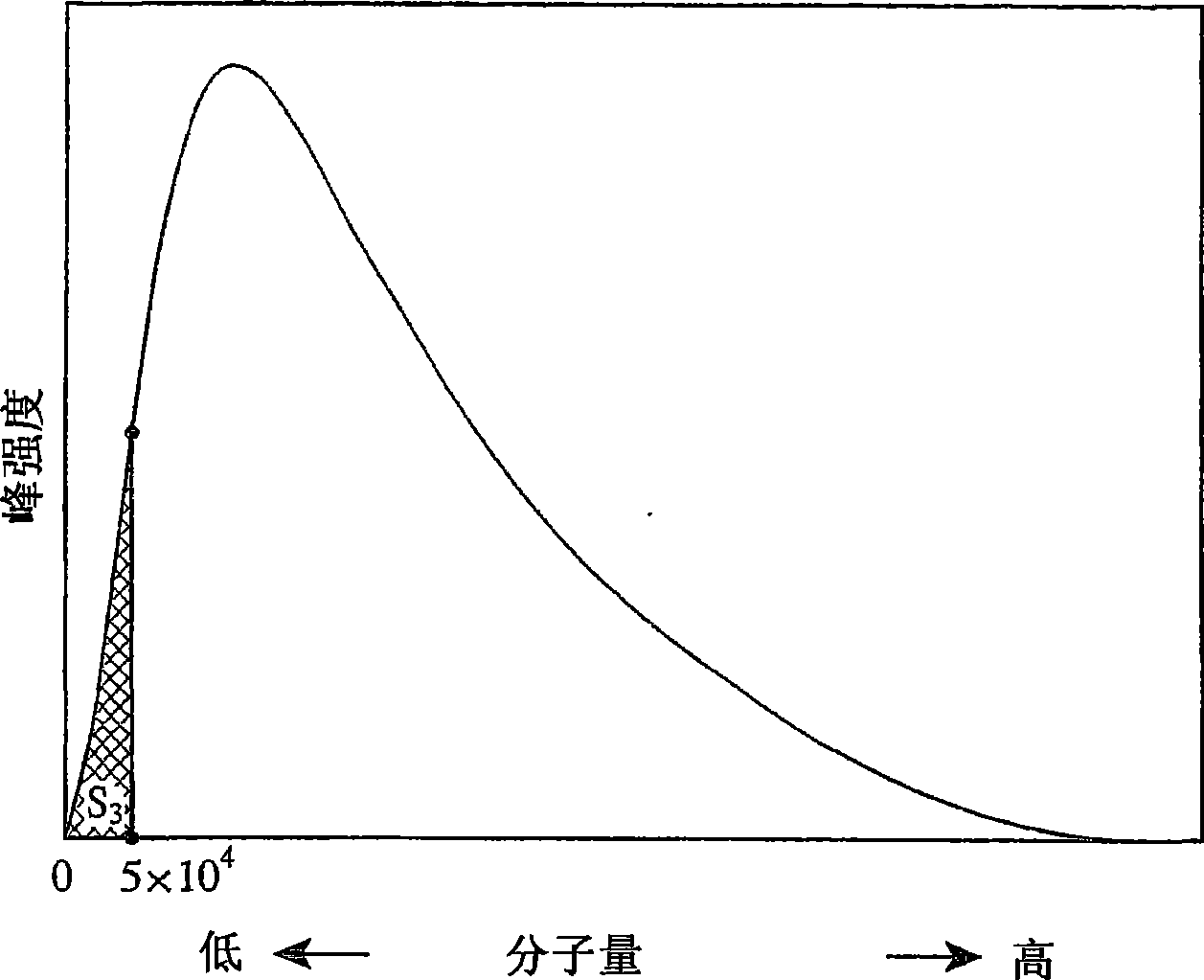

[0139] Mw and Mn of UHMWPE and HDPE were measured by gel permeation chromatography (GPC) under the following conditions.

[0140] · Measuring device: GPC-150C of Waters Company,

[0141] ・Column: Shodex UT806M of Showa Denko k.k. was used

[0142] ·Column temperature: 135℃

[0143] Solvent (mobile phase): o-dichlorobenzen...

Embodiment 2

[0169] The first and second polyolefin solutions were prepared in a separate twin-screw extruder in the same manner as in Example 1, and these solutions were fed from the twin-screw extruder into a T-die forming a three-layer sheet . Therefore, a laminate comprising the first polyolefin solution layer, the second polyolefin solution layer, and the first polyolefin solution layer in sequence was extruded such that the thickness of the second polyolefin solution layer was 15% of the overall thickness . The extrudate was cooled while passing through chill rolls controlled at 5°C, forming a three-layer gel-like sheet. Using tenter-stretching equipment, the three-layer gel-like sheet was simultaneously biaxially stretched at 118° C. so that the stretching ratio in the machine direction (MD) and transverse direction (TD) was 5x. The stretched three-layer gel-like sheet was washed, air-dried, and then fixed on a tenter, and subjected to a heat set treatment at 115° C. for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com