Mumm-shaped 3D TiO nanometer material and preparation method thereof

A nanomaterial, chrysanthemum technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increased cost, inability to prepare three-dimensional TiO, loss of titanium raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 0.1 gram of titanium powder and put it into 150ml of a mixed solution composed of 30% hydrogen peroxide and 0.1mol / L nitric acid. The molar ratio of hydrogen peroxide to nitric acid is 90:1. In an oven at 80°C, react for 120 minutes, then take it out immediately, and cool it in air. Measure 12ml of said solution with a graduated cylinder and mix it with 28ml of 40% sodium hydroxide solution with a mass fraction of 40% in a hydrothermal reactor with a capacity of 50ml. Minutes later, react in an oven at 150°C for 5 hours; after the reaction, wash the product with 0.1mol / L nitric acid and high-purity water for several times until the pH value reaches about 7; then bake in an oven at 80°C for 10 hours Dry.

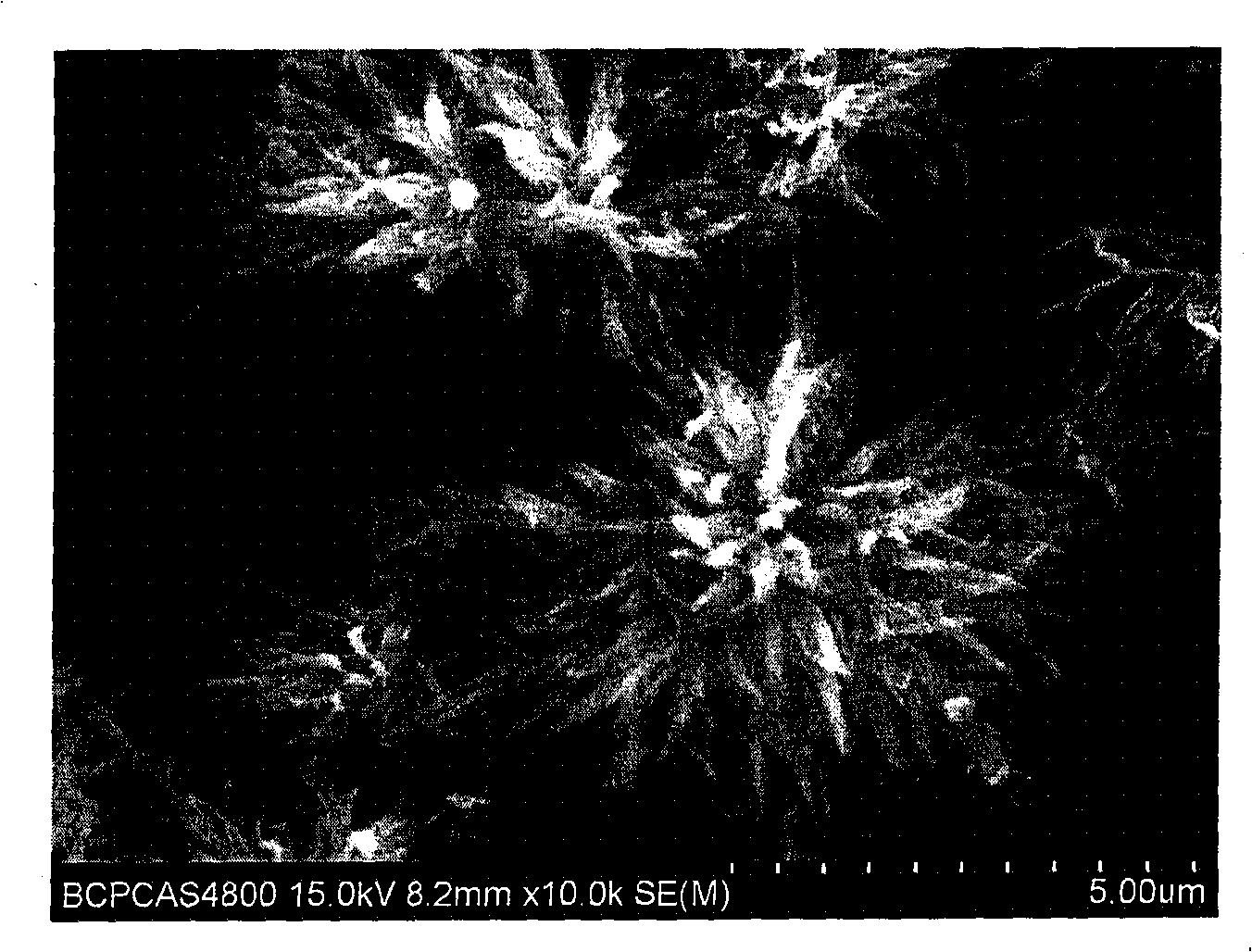

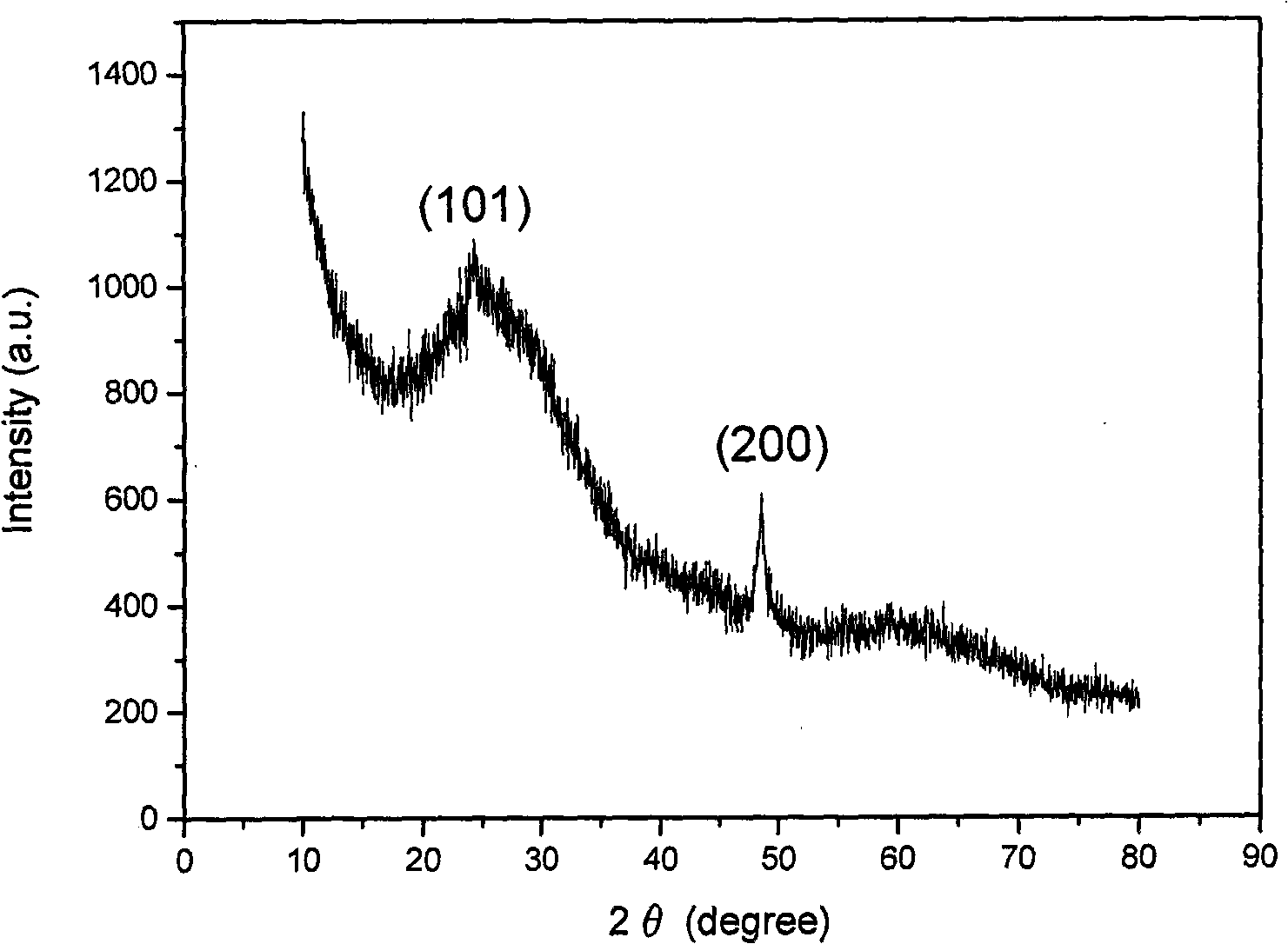

[0034] In this example, the solution obtained after the chemical treatment of titanium powder is a bright yellow solution, and the product after the hydrothermal reaction is a chrysanthemum-shaped three-dimensional TiO 2 nanomaterials.

[0035] figure 1 Shown...

Embodiment 2

[0037] Weigh 100 grams of titanium plates and put them into 1000ml of a mixed solution consisting of 30% hydrogen peroxide and 1mol / L hydrochloric acid. The molar ratio of hydrogen peroxide to hydrochloric acid is 9:1. After stirring evenly, put the solution into a solution whose temperature has reached In an oven at 50°C, react for 24 hours, then take it out immediately, and cool it in air. Dosage: Take 30ml of said solution and 30ml mass fraction of 30% potassium hydroxide solution and mix it in a hydrothermal reaction kettle with a capacity of 100ml. The volume ratio of titanium-containing solution and potassium hydroxide solution is 1: 1, stir for five Minutes later, react in an oven at 200°C for 1 hour; after the reaction, wash the product with 0.01mol / L hydrochloric acid and high-purity water for several times until the pH value reaches about 7; then bake in an oven at 100°C for 5 hours Dry.

[0038] The titanium-containing solution obtained in this embodiment is a brig...

Embodiment 3

[0040] Weigh 50 grams of titanium tube, put it into 500ml of mixed solution composed of 30% hydrogen peroxide and 0.5mol / L nitric acid, the molar ratio of hydrogen peroxide and nitric acid is 18:1; In an oven at 60°C; react for 20 hours, then remove immediately and cool in air. Measure 5ml of said solution with a graduated cylinder and mix it with 75ml of 10% potassium hydroxide solution in a 100ml capacity hydrothermal reactor. The volume ratio of titanium-containing solution to potassium hydroxide solution is 1: 15, and stir for five Minutes later, react in an oven at 180°C for 3 hours; after the reaction, wash the product with 1mol / L nitric acid and high-purity water several times until the pH value reaches about 7; then dry it in an oven at 70°C for 15 hours .

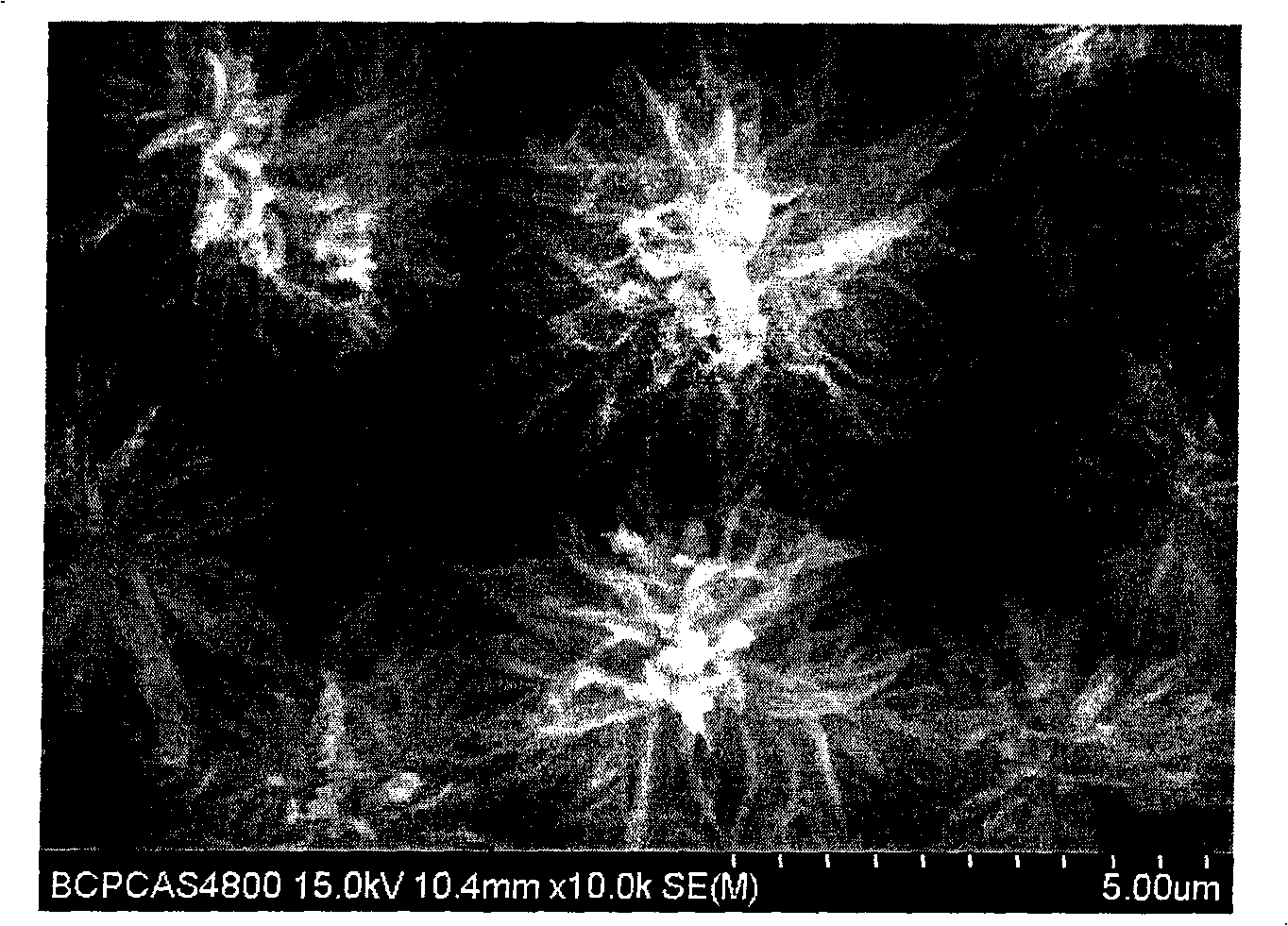

[0041] The titanium-containing solution obtained in this embodiment is a bright yellow solution, and the obtained TiO 2 Chrysanthemum-shaped three-dimensional TiO 2 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com