Control of waste paper stock micro-adhesive material by using low molecular weight and high cation substituted ratio starch

A cationic starch, high degree of substitution technology, used in the addition of sap control agent, pulping of cellulose raw materials, paper, etc., can solve the problems of poor effect and high price, and achieve good control ability, good water solubility, and high efficiency control. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

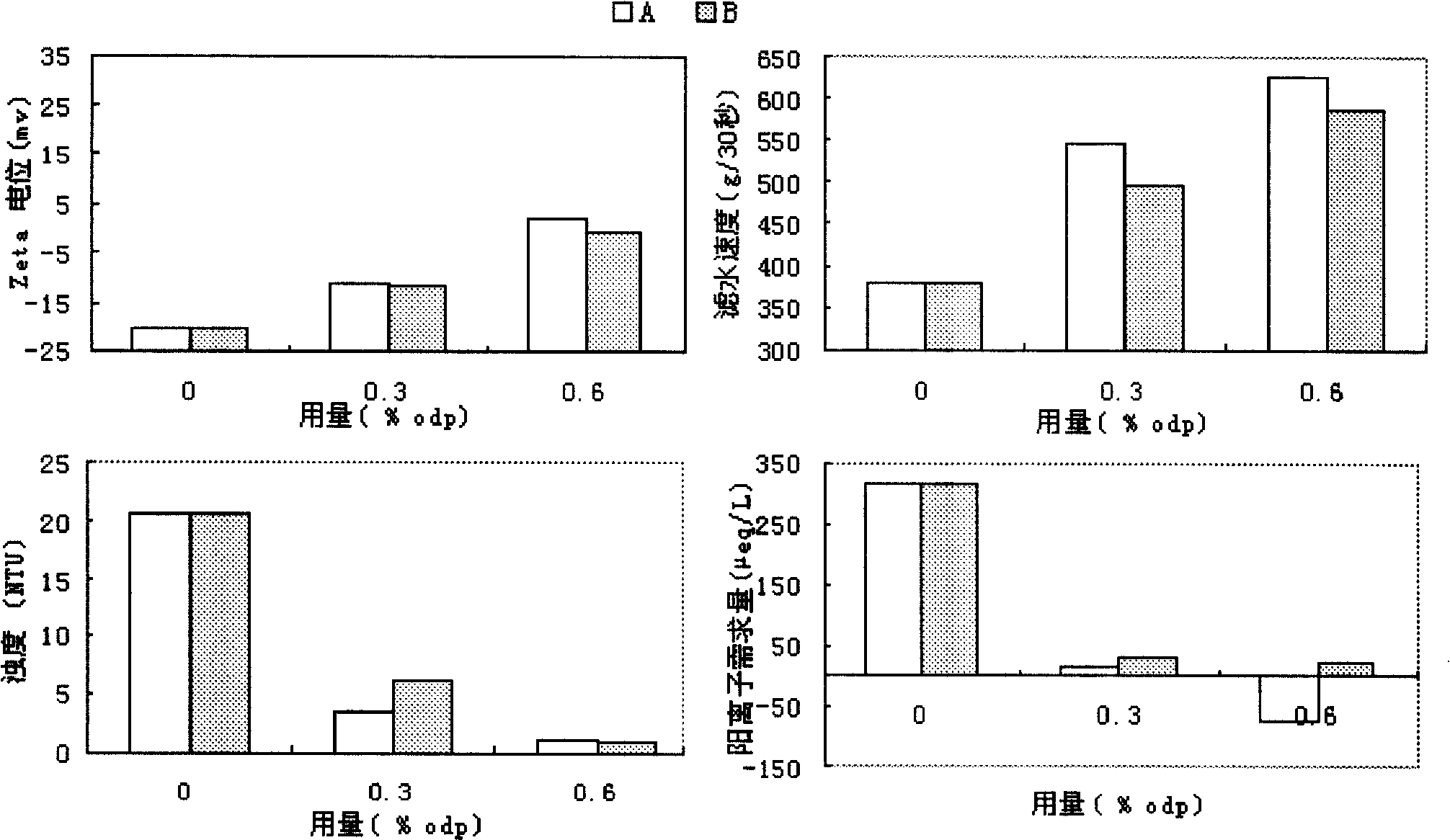

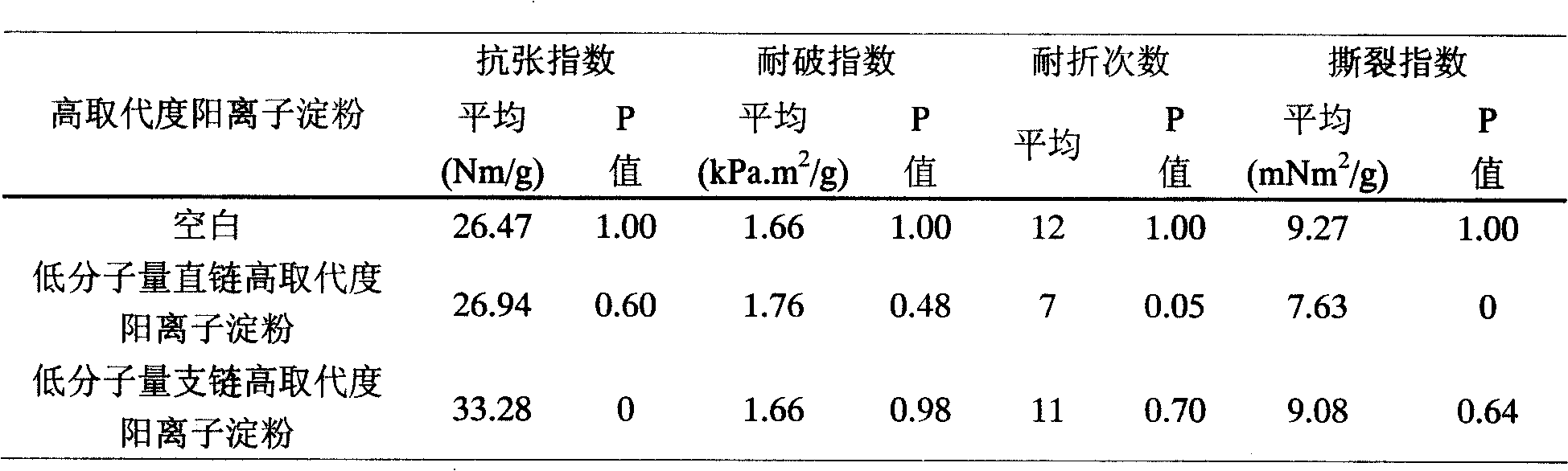

Examples

Embodiment 1

[0021] 1.1 Preparation of waste paper deinking pulp

[0022] Take 50g of absolutely dry waste newspaper, tear it into pieces, add 1000ml of water heated to 65°C, add 5ml of 50g / L sodium hydroxide, 7.5ml of 20g / L diethylenetriaminepentaacetic acid, 6ml of 100g / L sodium silicate , 12.5ml of 20g / L hydrogen peroxide, 5ml of 30g / L deinking agent, after mixing evenly, decompose in a standard decomposer for 20 minutes. Put the deflated slurry into a plastic bag and continue heating in a water bath at 65° C. for 30 minutes. After diluting the pulp concentration to 1%, carry out flotation deinking under a certain air flow, and the flotation time is 15 minutes. After deinking, filter the pulp with a 200-mesh mesh cloth, squeeze it dry, and balance the moisture for later use. When the self-made waste newsprint deinking pulp concentration was diluted to 3%, the cation requirement of the filtrate was measured to be 3.17mmol / L;

[0023] 1.2 Preparation of linear or branched highly substi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com