Method for preparing magnetic temperature-sensitive composite microsphere with nuclear shell structure by adopting in-situ grafting technique

A core-shell structure and composite microsphere technology, applied in the fields of polymer materials and biomedical engineering, can solve the problems of poor particle core-shell binding force, low magnetic content, and difficult control of the molecular weight of the shell polymer, and achieve a synthesis method. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

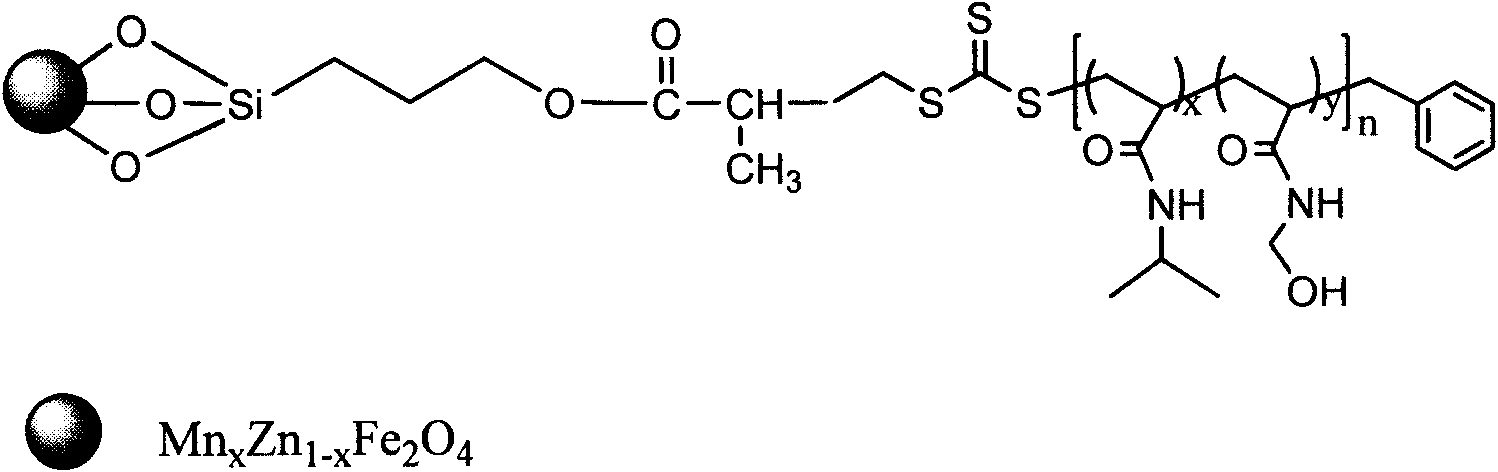

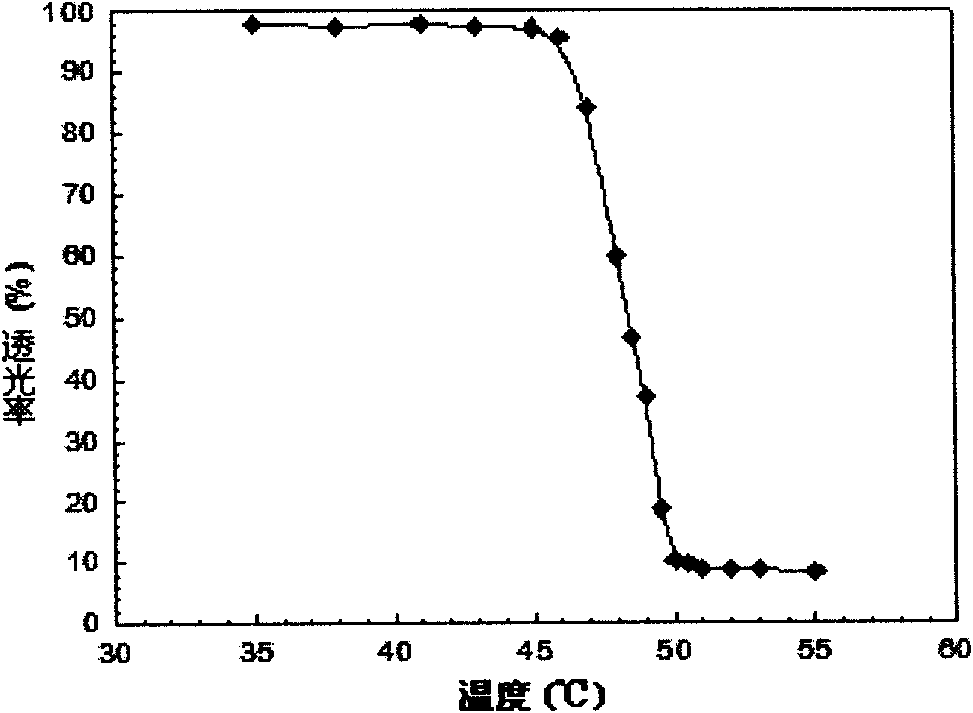

Embodiment 1

[0021] In 100ml of 5% silane coupling agent KH-570 ethanol solution, add 0.5g ferroferric oxide nano-magnetic particles for ultrasonic dispersion, raise the temperature to 60°C for 6 hours, wash the product with ethanol five times after magnetic separation, put Dry in a vacuum oven. Disperse the prepared dry magnetic particles in 50ml N,N-dimethylformamide, weigh 1.13g monomer N-isopropylacrylamide (NIPAAm), 1.00g N,N-dimethylacrylamide, 0.33 g azobisisobutyronitrile, 0.96g isocyanopropyl dithiobenzoate, carry out solution polymerization, the polymerization temperature is 80 ℃, and the polymerization time is 3 hours, after magnetic separation and vacuum drying of the obtained product to obtain magnetic temperature-sensitive composite microspheres, the particle diameter of the composite microspheres is monodisperse and within the range of 30nm-500nm. figure 1 is the molecular structure formula of the magnetic composite microsphere, from figure 2 It can be seen that the compo...

Embodiment 2

[0023] In 500ml of 6% silane coupling agent KH-570 ethanol solution, add 10g ferroferric oxide nano-magnetic particles for ultrasonic dispersion, raise the temperature to 50°C for 16 hours, wash the product with acetone five times after magnetic separation, put Vacuum oven dry. Disperse the prepared dry magnetic particles in 250ml 1,4-dioxane, weigh 22.6g monomer N-isopropylacrylamide (NIPAAm), 40.0g N,N-diethylacrylamide, 0.6568 g benzoyl peroxide, 3.24g cumyl dithiobenzoate, carry out solution polymerization, the polymerization temperature is 75 ℃, and the polymerization time is 6 hours. After magnetic separation and vacuum drying of the obtained product, a magnetic Thermosensitive composite microspheres. The particle size of the composite microsphere is monodisperse and within the range of 30nm-500nm. Fig. 1 is the molecular structural formula of the magnetic composite microsphere, from figure 2 It can be seen that the composite microspheres have good temperature-sensit...

Embodiment 3

[0025] In 1000ml of 4% silane coupling agent KH-570 ethanol solution, add 15g of iron ferric oxide nano-magnetic particles for ultrasonic dispersion, raise the temperature to 70°C for 10 hours, and wash the product with tetrahydrofuran five times after magnetic separation. Vacuum oven dry. Disperse the prepared dry magnetic particles in 150ml N,N-diethylformamide, weigh 11.3g monomer N-isopropylacrylamide (NIPAAm), 10.0g N,N-dimethylacrylamide, 10.0 gN, N-diethylacrylamide, 0.3284g dilauroyl peroxide, 1.21g α-dithionaphthoic acid isobutyronitrile, carry out solution polymerization, the polymerization temperature is 70 ℃, and the polymerization time is 8 hours, will obtain Magnetic temperature-sensitive composite microspheres were obtained after magnetic separation and vacuum drying of the product. The particle size of the composite microsphere is monodisperse and within the range of 30nm-500nm. figure 1 is the molecular structure formula of the magnetic composite microsphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com