Method for preparing metal bismuth nanoparticle

A bismuth nanometer and metal technology is applied in the field of preparation of metal bismuth nanoparticles, which can solve the problems of no bismuth nanoparticles and high production cost, and achieve the effects of low cost, cheap raw materials and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

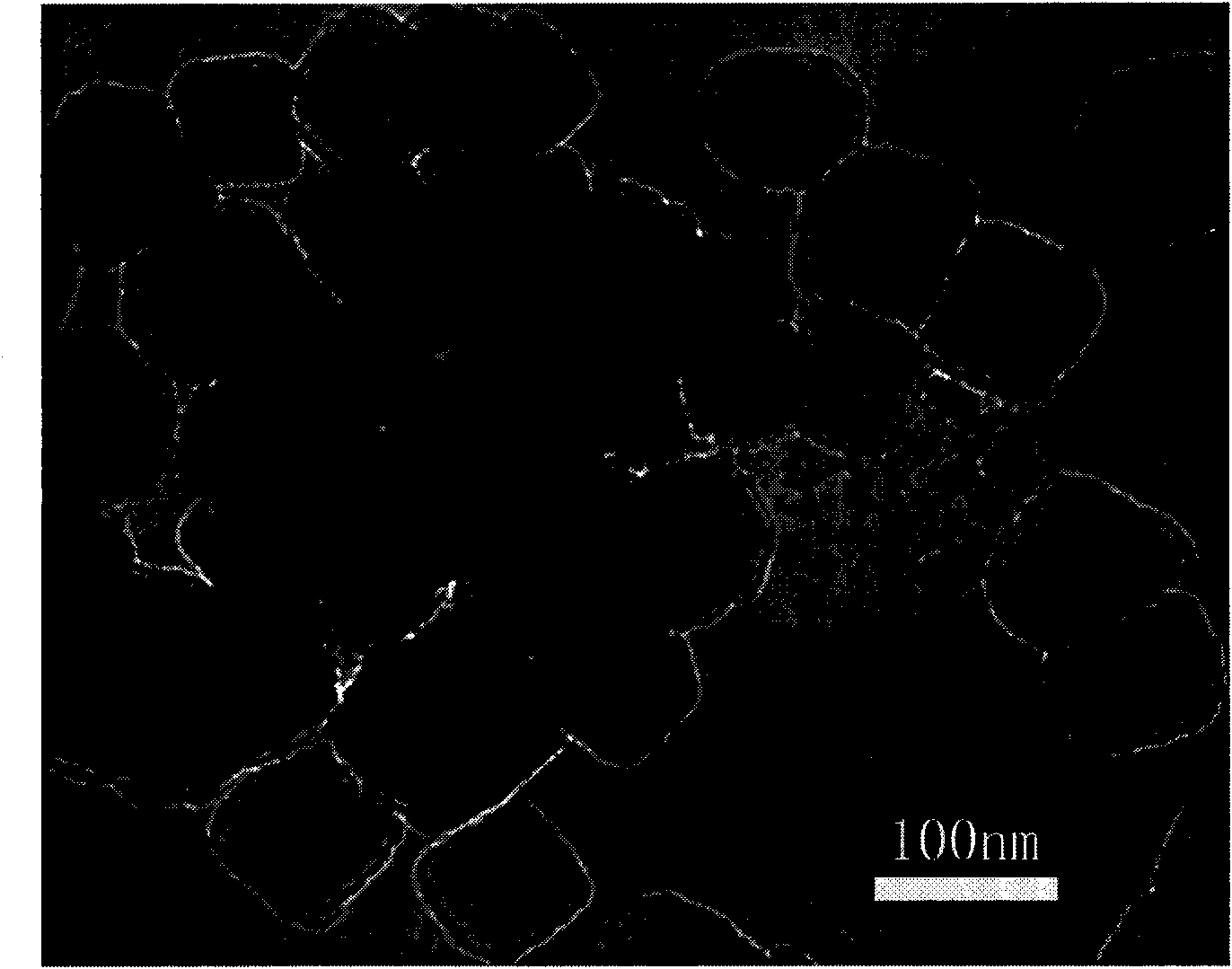

[0031] Weigh 0.243g bismuth nitrate pentahydrate, dissolve in 10mL distilled water, add 0.73gC 22 10ml of petroleum ether solution of DDP, at room temperature (20°C), stir for 10min to mix evenly, then slowly add 10mL of hydrazine monohydrate solution containing 1.2mol / L dropwise, the dropping rate is about 1mL / min, the temperature is controlled at 50°C, at 1350r Stir and reflux reaction at a speed of 1 / min for 1 h, let stand to separate layers, discard the lower layer, take the upper black organic phase, distill under reduced pressure (60 ° C, vacuum degree 0.05Mpa, 30 min), add acetone to wash centrifugally, and dry to obtain a black powder. That is metal bismuth nanoparticles, the actual yield is about 91.5% of the theoretical value; figure 1 As shown, it can be seen that the shape of the prepared nanoparticles is approximately cubic, the surface has a layer of organic coating, and the particle size is relatively uniform, between 50 and 100nm; the X-ray diffraction pattern ...

Embodiment 2

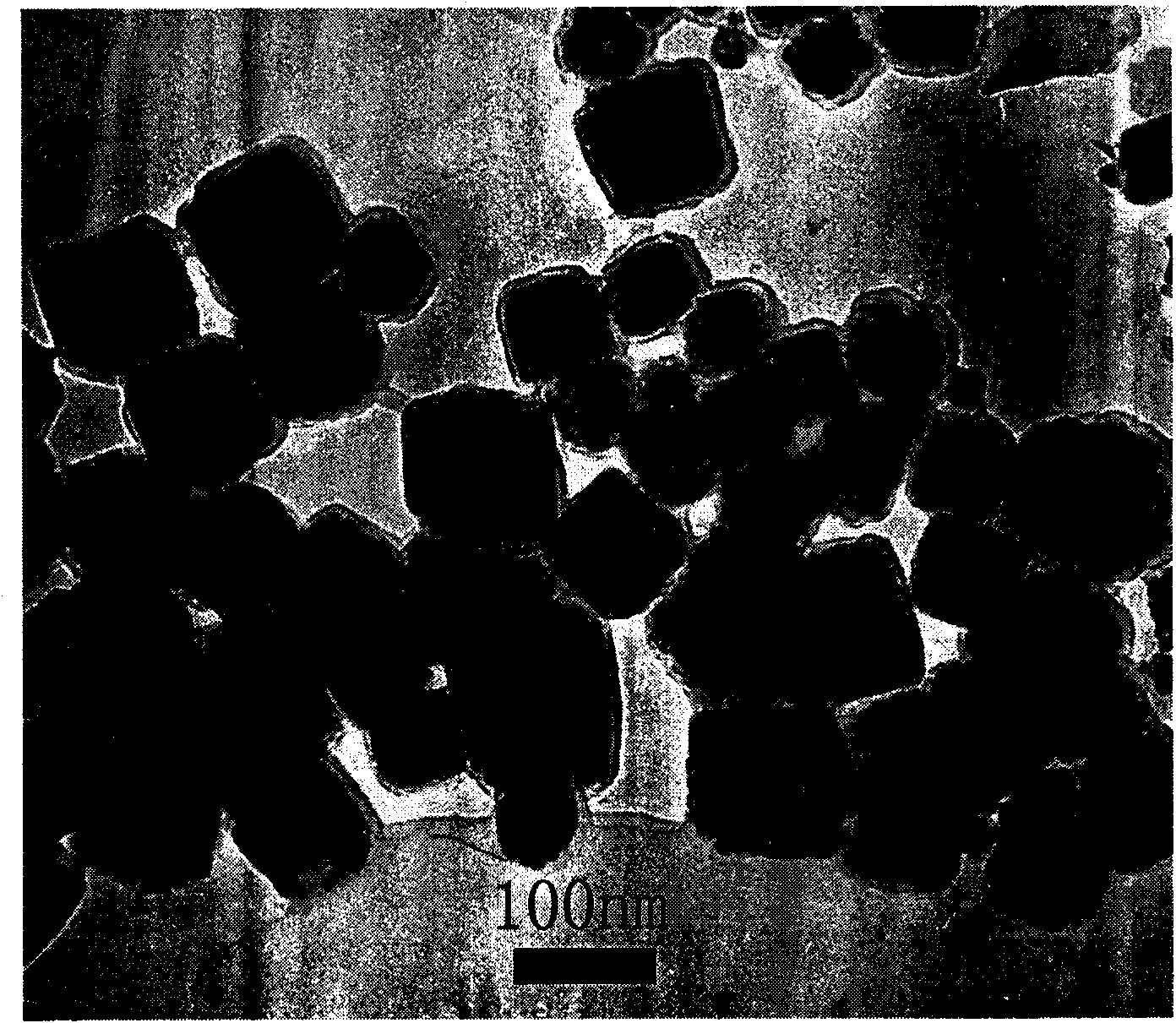

[0033] Weigh 0.388g bismuth nitrate pentahydrate, dissolve in 10mL distilled water, add 0.899gC 16 Chloroform solution 10ml of DDP, room temperature (20 ℃), stir 40min to mix evenly, then slowly dropwise add 10mL of the mixed clear solution containing 0.226g tin protochloride dihydrate and 0.8g sodium hydroxide, the rate of addition is about 1mL / min, Control the temperature at 65°C, stir and reflux at a speed of 1500r / min for 2.5h, let stand to separate layers, remove the lower black organic phase, distill under reduced pressure (70°C, vacuum degree 0.07Mpa, 25min), add acetone, centrifuge, wash, and dry , to obtain black powder, which is metal bismuth nanoparticles, and the actual yield is about 91.5% of the theoretical value; figure 2 As shown, it can be seen that the prepared nanoparticles have a cubic structure, and the particle size distribution is relatively uniform, ranging from 50 to 80 nm; the obtained black powder is dispersed in petroleum ether, and no obvious prec...

Embodiment 3

[0035] Weigh 0.212g anhydrous bismuth sulfate, dissolve in 10mL distilled water, add 0.9g C 12 10ml of n-hexane solution of DDP, at room temperature (20°C), stir for 15min to mix well, then slowly add 10mL of the mixed clear solution containing 0.677g of stannous chloride dihydrate and 1.2g of sodium hydroxide dropwise at a rate of about 1mL / min , the temperature was controlled at 60°C, stirred and refluxed at a speed of 1650r / min for 2h, allowed to stand for stratification, and the upper black organic phase was taken, distilled under reduced pressure (65°C, vacuum degree 0.06Mpa, 28min), added acetone for centrifugal washing, and dried Obtain black powder, be metal bismuth nanoparticle, actual productive rate is about 88.4% of theoretical value; Transmission electron microscope picture is as image 3 As shown, it can be seen that the shape of the obtained nanoparticles is mainly cubic, and the particle size distribution is relatively wide, between 50-120nm; the obtained black...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com