Purification system of straw quick thermal cracking products

A technology of purification system and cracking system, which is applied in the field of purification system of rapid thermal cracking products of straw, can solve problems such as difficulties in purification and treatment of biomass oil and gas, and achieve the effects of improving performance, high quality, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

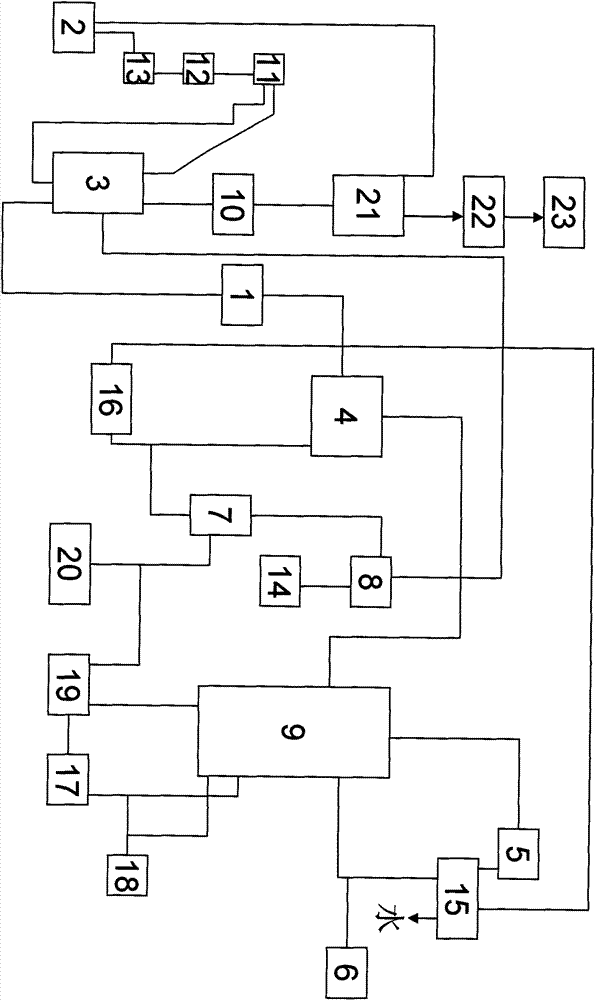

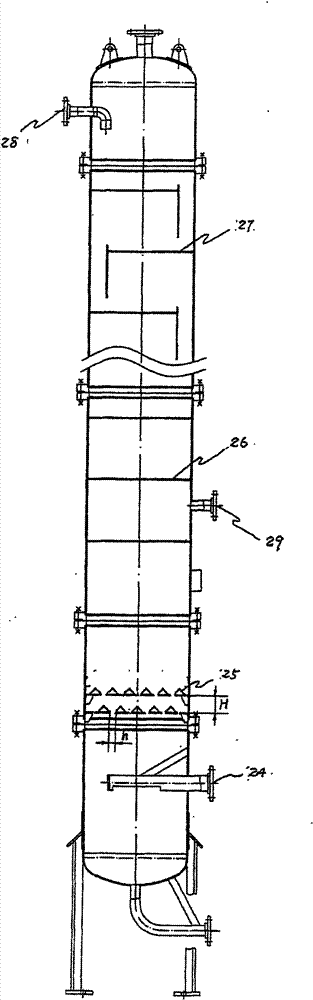

[0027] Example 1. A purification system for fast pyrolysis products of straw, such as figure 1 , figure 2 shown. It includes a trough 2 for crushing straw materials, a silo 10 for transporting the material in the trough 2 to it through a distributor 21, a cracking furnace 3 connected to the silo 10, and a material outlet of the cracking furnace 3. The pyrolysis system dust collector 4. The hot air outlet of the air preheater 11 is connected to the bottom of the cracking furnace 3 . The bottom outlet of the cracking system dust collector 4 is connected with the carbon powder cooler 7, and the top outlet of the cracking system dust collector 4 is connected with the inlet of the rectification washing tower 9. The top outlet of the carbon powder cooler 7 is connected to the carbon powder dust collector 8 , the bottom outlet of the carbon powder dust collector 8 is connected to the carbon powder storage tank 14 , and the top gas outlet of the carbon powder dust collector 8 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com