Preparation method of calcitriol

A technology for calcitriol and compound, which is applied in the field of preparation of compound raw material calcitriol, can solve the problems of unsuitable separation of calcitriol, high impurities in the separation result and high analysis cost, and saves time for separation and preparation , the method selection is reasonable, the effect of the efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

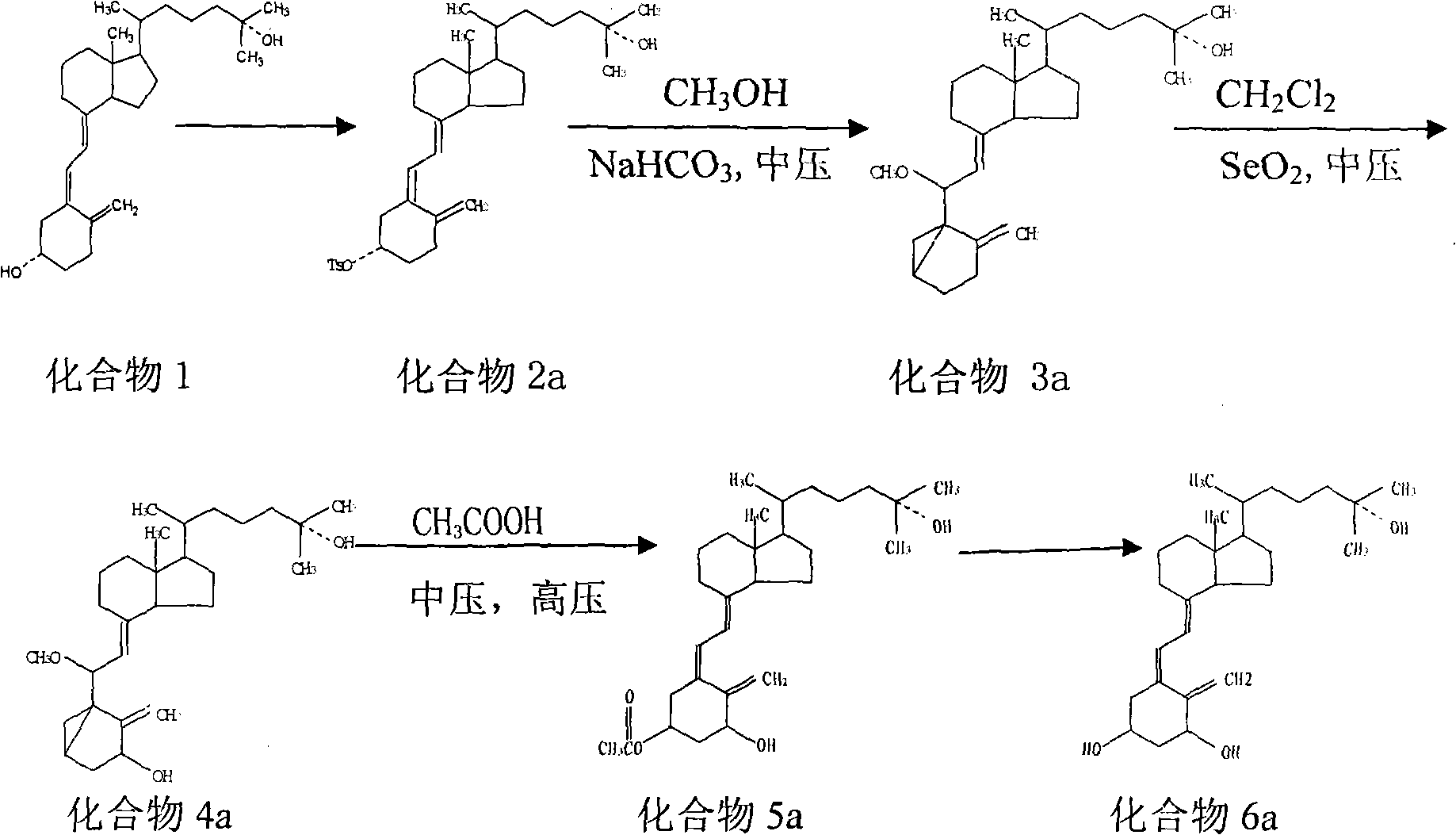

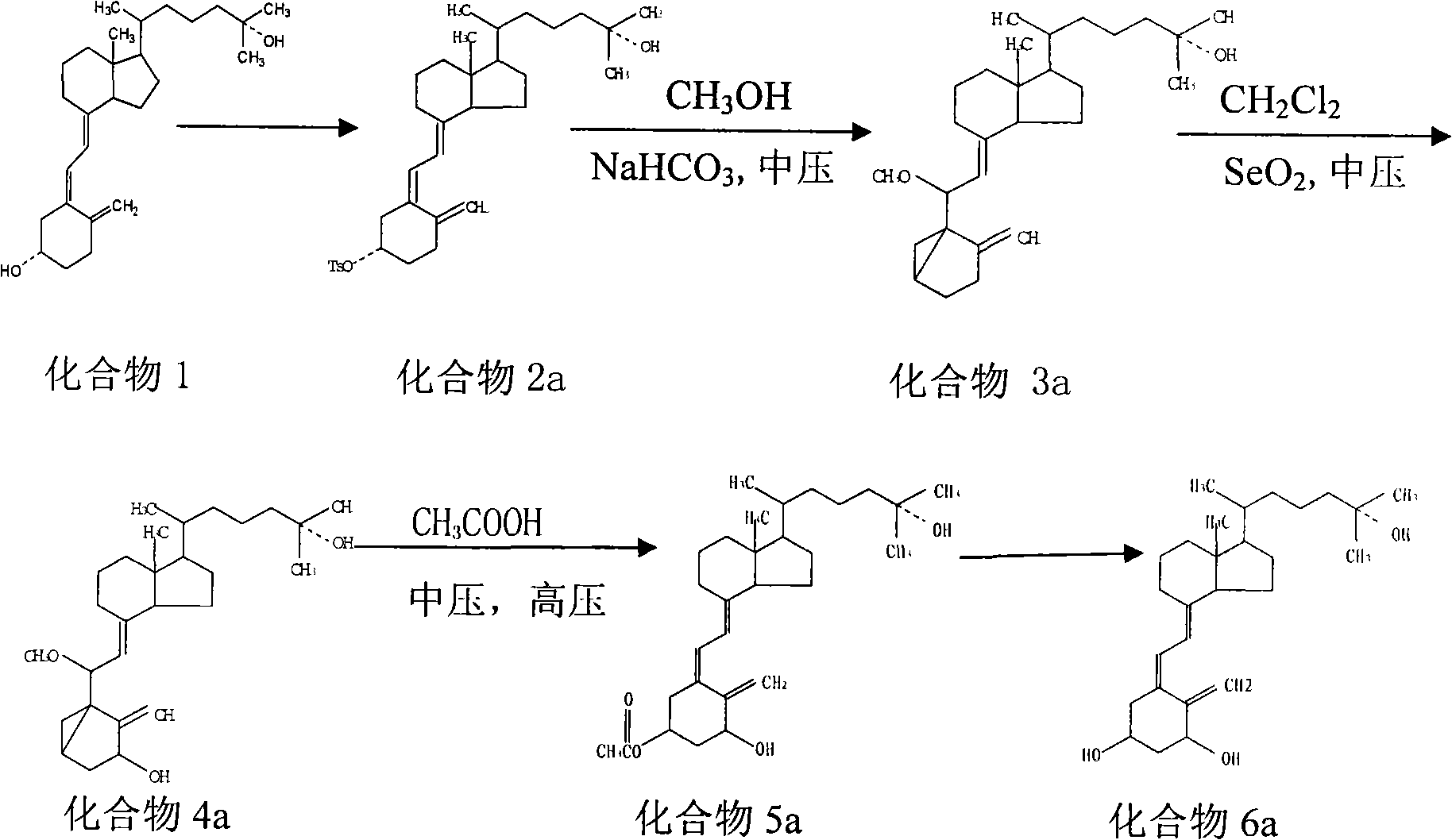

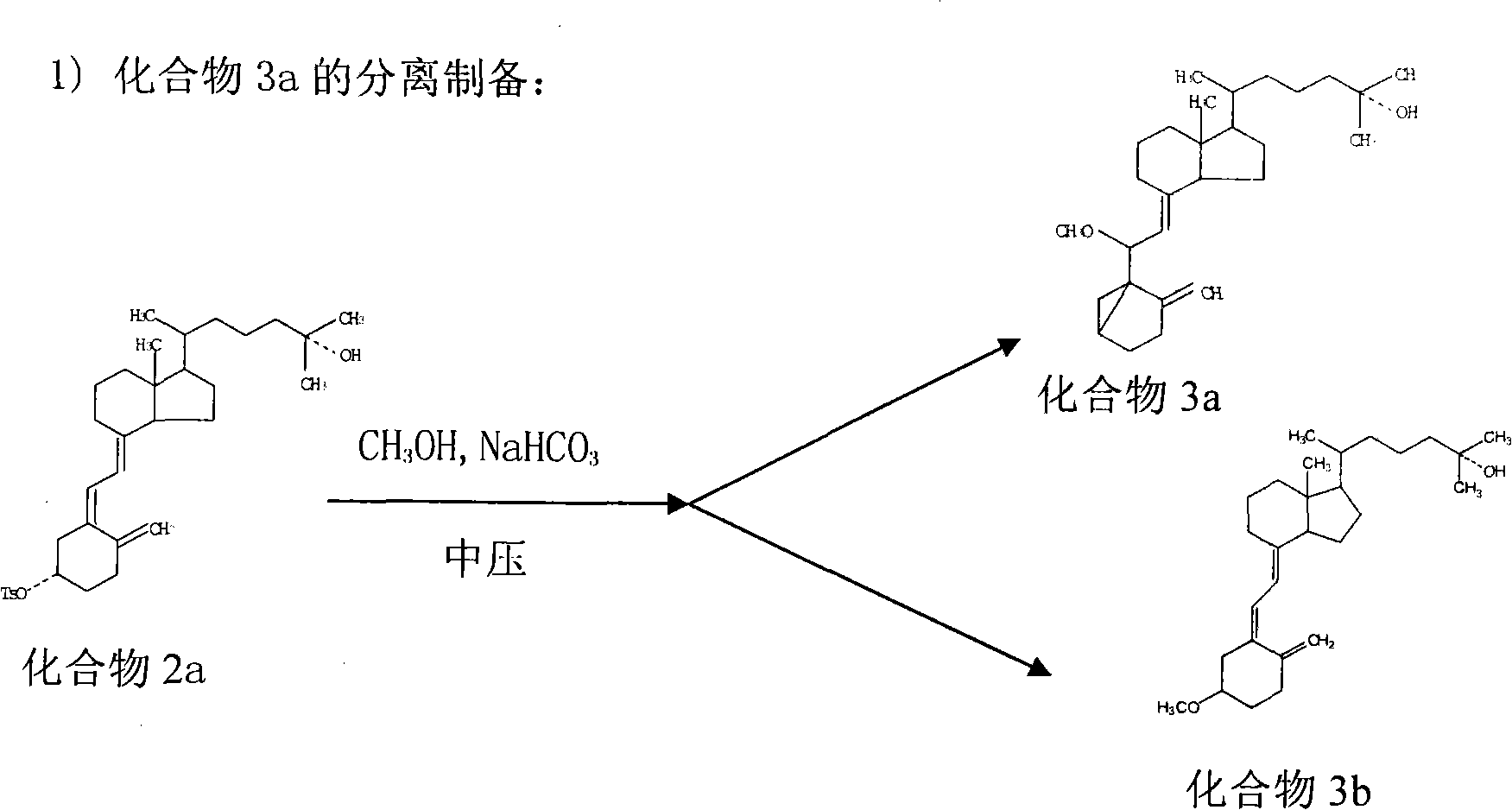

[0023] The main process involved in this embodiment is the same as in the summary of the invention, wherein the three specific processes of the separation and preparation of compound 3a, the separation and preparation of compound 4a and the separation and preparation of compound 5a are as follows:

[0024]

[0025] Add compound 2a and sodium bicarbonate to methanol in turn, stir and maintain the temperature at 30°C, and use thin-layer chromatography (thin-layer chromatography conditions: silica gel is GF254; developing solvent: ethyl acetate-cyclohexane 3:1; The color agent is 5% phosphomolybdic acid or ethanol) to detect the degree of progress of the reaction; after the reaction is substantially complete, the methanol is recovered under reduced pressure and extracted with ethyl acetate, after drying and concentrating, the medium-pressure liquid chromatography column is used, and the mobile phase is ethyl acetate : Cyclohexane 1: 20, the flow rate is 10ml / min for elution, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com