Method for preparing nano silicon dioxide coated by nano titanium dioxide

A technology of nano-silica and nano-titanium dioxide, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., to achieve good social and economic benefits, uniform particle size distribution, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

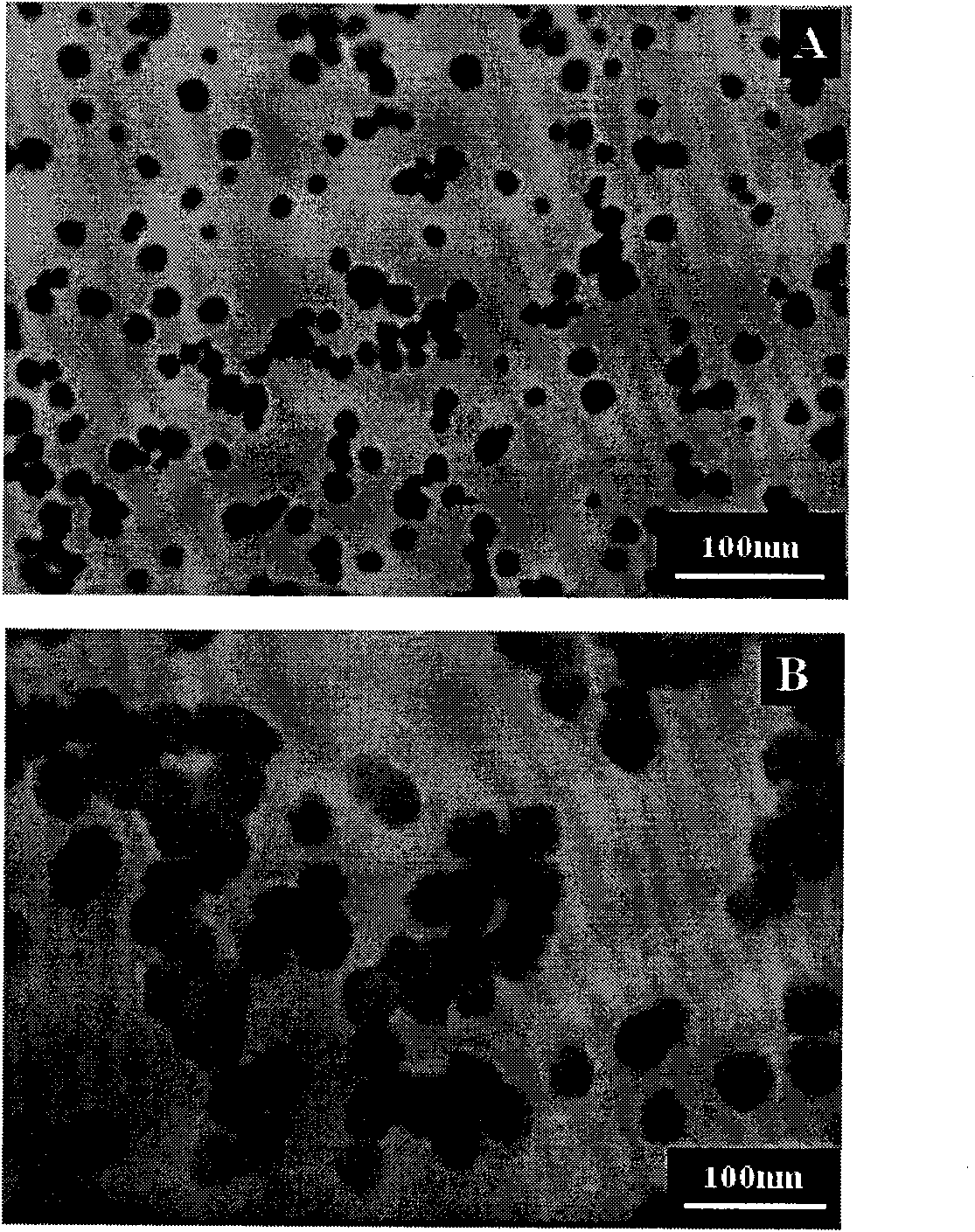

Image

Examples

Embodiment 1

[0025] A preparation method of nano-titanium dioxide-coated nano-silicon dioxide composite material, the steps are:

[0026] In the first step, under the conditions of stirring and ultrasonic waves, add 0.1 mol / L hydrochloric acid dropwise to the sodium silicate solution with a concentration of 0.1 mol / L, control the pH value of the reaction system to 5.5, and the reaction temperature to 25°C. React for 30 minutes and let stand for 0.5 hours to obtain white or transparent silicic acid sol; dry the white or transparent silicic acid sol at 65°C for 2 hours to obtain white silicic acid gel; Mix the gel with distilled water whose volume is 1 times the volume of the silicic acid gel, ball mill for 10 minutes, wash the ball-milled silicic acid gel with distilled water until the eluate is neutral or chlorine ions are detected, filter under reduced pressure (less than 100Kpa), A white silicic acid gel solid is obtained; thermally decompose the white silicic acid gel solid at 150°C to ...

Embodiment 2

[0031] A preparation method of nano-titanium dioxide-coated nano-silicon dioxide composite material, the steps are:

[0032] In the first step, under the conditions of stirring and ultrasonic waves, add dropwise a mixed solution of hydrochloric acid and sulfuric acid with a total concentration of 2mol / L to the sodium silicate solution with a concentration of 2mol / L to control the pH of the reaction system The value is 9.5, the reaction temperature is 25°C, react for 30 minutes, and stand for 1 hour to obtain white or transparent silicic acid sol; dry the white or transparent silicic acid sol at 100°C for 12 hours to obtain white silica acid gel; mix the white silicic acid gel with distilled water twice the volume of the silicic acid gel, ball mill for 10 minutes, and wash the ball-milled silicic acid gel with distilled water until the eluate is neutral or free of chloride ions. out, vacuum filtration (less than 100Kpa) or centrifugation to obtain a white silicic acid gel, whic...

Embodiment 3

[0037] A preparation method of nano-titanium dioxide-coated nano-silicon dioxide composite material, the steps are:

[0038] In the first step, under the conditions of stirring and ultrasonic waves, add 1 mol / L nitric acid dropwise to the potassium silicate solution with a concentration of 1 mol / L, control the pH value of the reaction system to 6.5, and the reaction temperature to 35°C. Minutes, let it stand for 1 hour to get white or transparent silicic acid sol; dry the white or transparent silicic acid sol at 80°C for 2 to 24 hours to get white silicic acid gel; white silicic acid gel Mix the gel with distilled water three times the volume of the silicic acid gel, ball mill for 20 minutes, wash the ball-milled silicic acid gel with distilled water until the eluate is neutral, filter under reduced pressure (less than 100Kpa) or centrifuge to obtain a white Silicic acid gel, thermally decompose white silicic acid gel at 250°C to obtain white nano-silica powder;

[0039] The ...

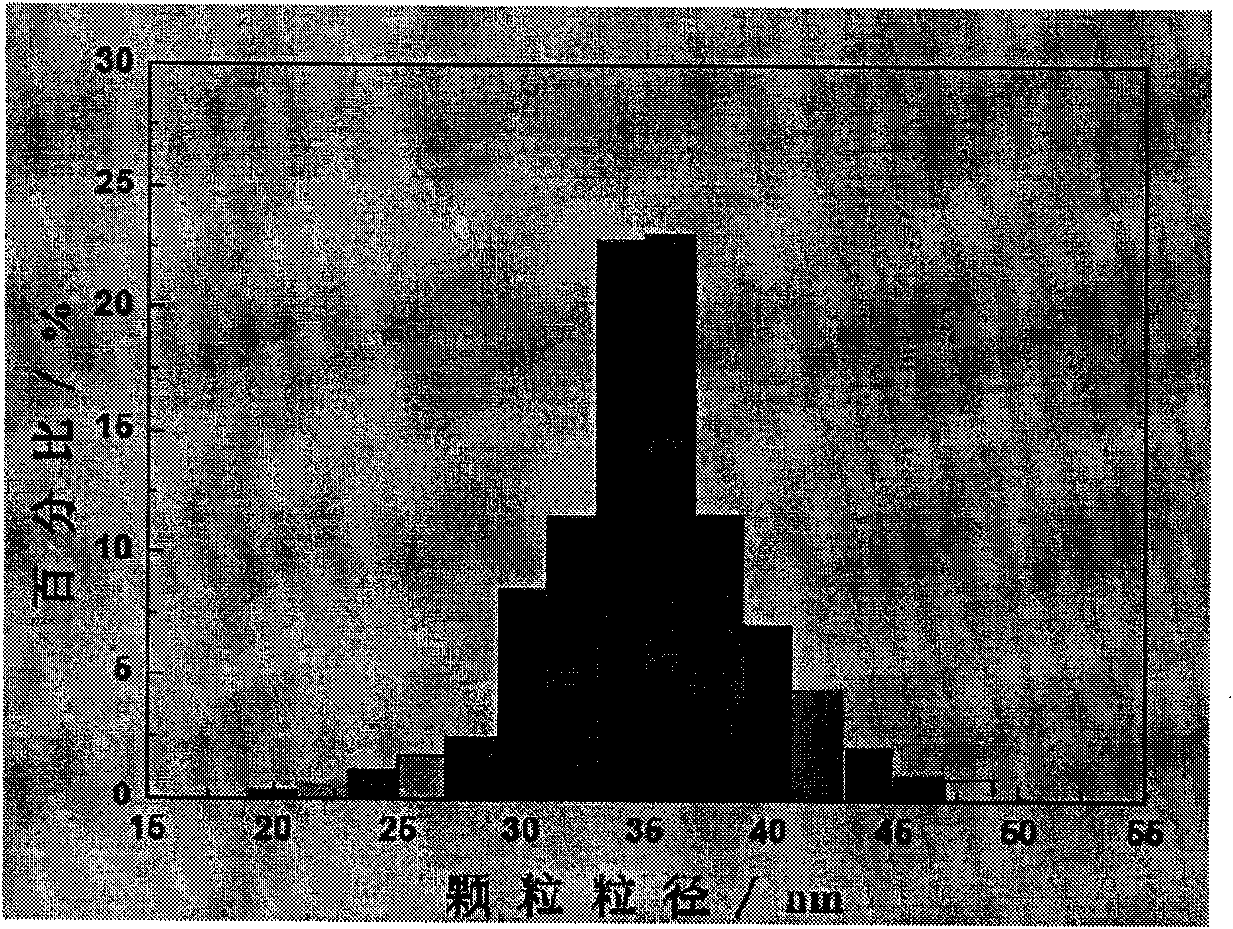

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com