Backward extraction method for extracting rapeseed protein by reverse micelle

A technology of rapeseed protein and reverse micelles, which is applied to the preparation method of peptides, chemical instruments and methods, plant peptides, etc., can solve the problems of low protein extraction rate and surfactant loss, and achieve high protein extraction rate and production Low cost and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

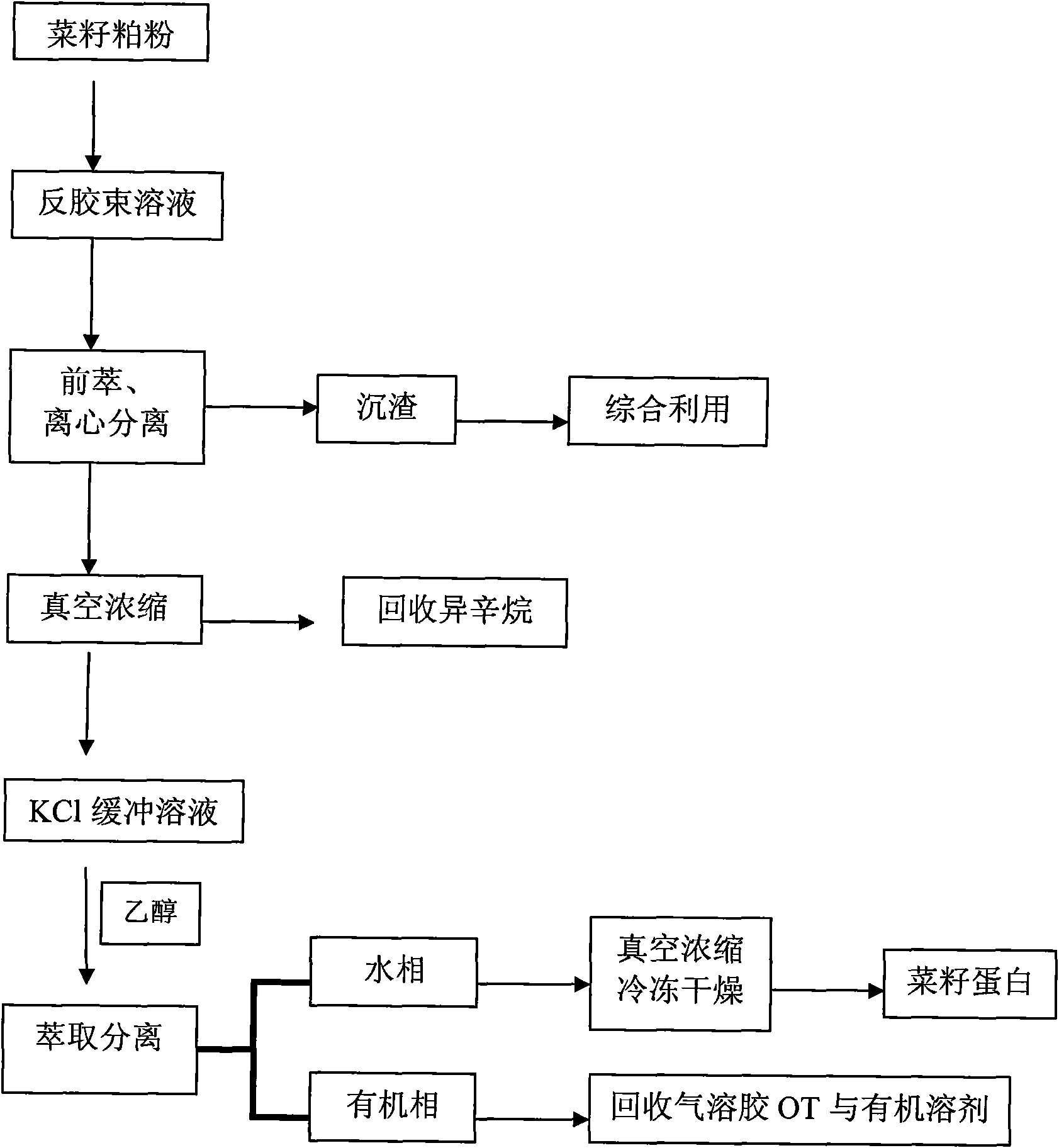

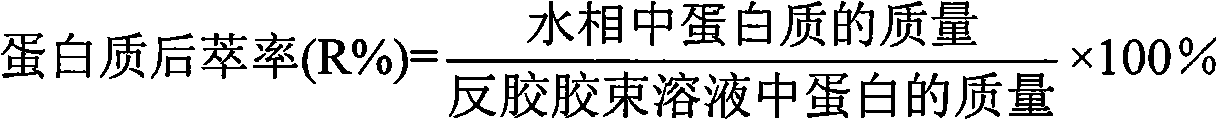

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of rapeseed meal powder:

[0036] The high-quality double-low rapeseeds produced in 2008 were selected, hulled on a huller, and air-selected after treatment. The shelled rapeseed is crushed on a hammer cyclone mill, and passed through a 100-mesh sieve after crushing. Use petroleum ether (boiling range of 30-60°C) on a Soxhlet extractor to deoil the crushed rapeseed at 50°C, and place it in a ventilated place for precipitation after treatment, so that the petroleum ether can be completely volatilized. Ventilated and dried again, the gained is the required rapeseed meal powder for the test, and its protein (N×6.25 dry basis) content is measured to be 50.1%.

[0037] (2) Configuration of reverse micellar solution

[0038] Preparation of KCl buffer solution: Weigh 110.8g disodium hydrogen phosphate dihydrate and 9.07g potassium dihydrogen phosphate to prepare 1L of solution, mix 190mL and 10mL respectively, and then add 0.596g potassium chloride to the abo...

Embodiment 2

[0050] (1) Preparation of rapeseed meal powder:

[0051] The high-quality double-low rapeseeds produced in 2008 were selected, hulled on a huller, and air-selected after treatment. The shelled rapeseed is crushed on a hammer cyclone mill, and passed through an 80-mesh sieve after crushing. Use petroleum ether (boiling range of 30-60°C) on a Soxhlet extractor to deoil the crushed rapeseed at 50°C, and place it in a ventilated place for precipitation after treatment, so that the petroleum ether can be completely volatilized. Ventilated and dried again, the gained is the required rapeseed meal powder for the test, and its protein (N × 6.25, dry basis) content is 45.6%.

[0052] (2) Preparation of reverse micellar solution

[0053] KCl buffer solution preparation: prepare 0.2mol L -1 Disodium hydrogen phosphate solution and 0.1mol·L -1 1L of each citric acid solution, take 10.30mL and 9.70mL respectively and mix well. Get 0.1193g potassium chloride again and add in the above-...

Embodiment 3

[0064] (1) Preparation of rapeseed meal powder:

[0065] The high-quality common rapeseeds produced in 2008 were selected for hulling treatment on a huller, and then winnowed after treatment. The shelled rapeseed is crushed on a hammer cyclone mill, and passed through an 80-mesh sieve after crushing. Use petroleum ether (boiling range of 30-60°C) on a Soxhlet extractor to deoil the crushed rapeseed at 50°C, and place it in a ventilated place for precipitation after treatment, so that the petroleum ether can be completely volatilized. Ventilated and dried again, the gained is the rapeseed meal powder required for the test, and its protein (N×6.25, dry basis) content is 43.21%.

[0066] (2) Preparation of reverse micellar solution:

[0067] KCl buffer solution preparation: prepare 50mL 0.05mol L respectively -1 Disodium hydrogen phosphate solution and 4.1mL 0.1mol·L -1 Sodium hydroxide, mix well, add water to dilute to 100mL, and take 1.118g of potassium chloride and add to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com