Enzyme composition for high-efficiency decomposition of cellulose

A technology of cellulase and enzyme composition, applied in the direction of drilling composition, detergent composition, non-surface active detergent composition, etc., to achieve the effects of increased production, enhanced enzyme activity, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

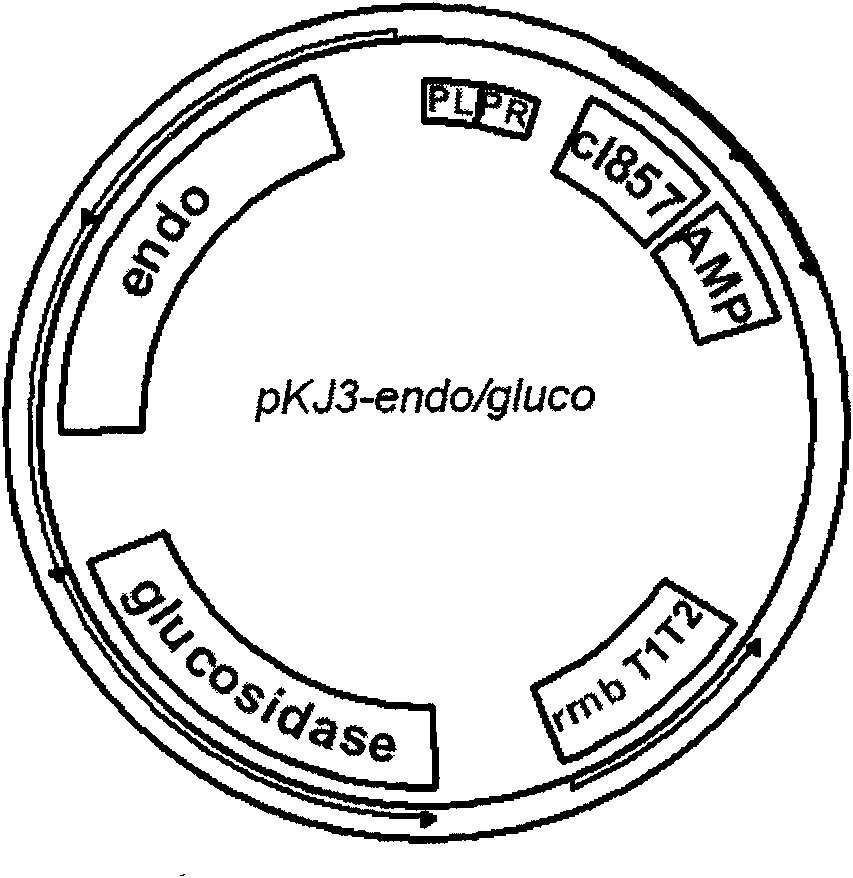

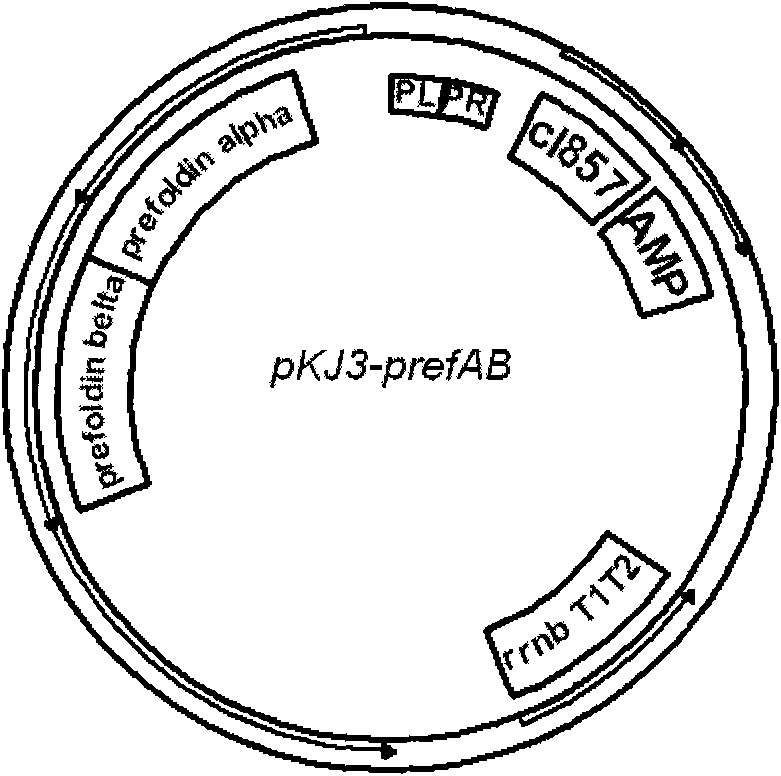

[0068] Example 1 Acquisition of cellulase gene

[0069] The gene fragment in the present invention is obtained from a thermophilic archaea Pyrococcus horikoshii OT3 (JCM9974), which is purchased from Riken (the Institute of Physical and Chemical Research), JAPAN. The entire genomic DNA of this thermophilic archaea has been sequenced.

[0070] The thermophilic bacterium pyrococcus horikoshii OT3 was cultured statically at 95°C for 16 hours (see the catalog of the Japan Collection of Microorganisms for specific culture methods). Genomic DNA was extracted by QIAamp DNA mini Kit (Qiagen.com, Valencia, CA, USA. Cat#51304). The inventors designed the following primers based on the genomic DNA sequence of the thermophile pyrococcus horikoshii OT3, and obtained two cellulase genes of different lengths and two subunit genes of Prefoldin (PFD) by polymerase chain reaction.

[0071] 1.1 Endo-1,4-glucanase PH1171

[0072] The optimized gene constructs with full-length gene and partial ...

Embodiment 2

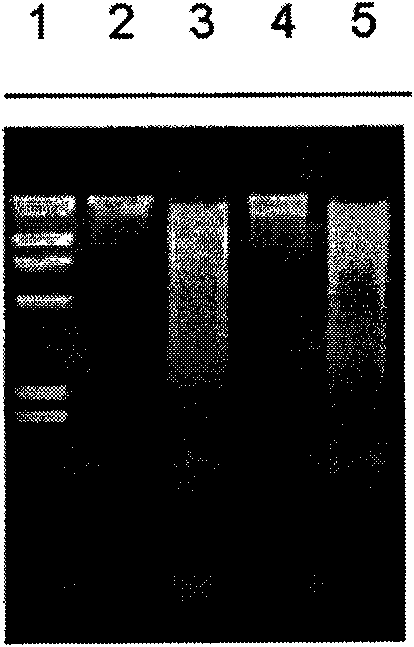

[0103] Example 2 Positive clone identification of cellulase gene

[0104] 2.1 Determination of biological activity of endo-1,4-glucanase:

[0105] The transformants (pET / PH1171-458 full-length gene or its optimized construct) containing the insert fragment were respectively copied to a medium containing 0.5% carboxymethyl cellulose (CMC) and 1 mM IPTG by lithographic method. On the LB agar medium plate (SIGMA company, C-5678), copy the same transformant to another LB agar medium plate containing 100 μg / ml ampicillin at the same time, and place the two plates in a 37-degree incubator for cultivation After 20 hours, put the ampicillin LB agar medium plate with colonies in a 4-degree incubator for preservation. Another LB agar medium plate containing CMC was fumigated with chloroform vapor to lyse the cells, then stained with 0.5% Congo red solution for 20 minutes, decolorized with 1M NaCI solution for 20 minutes, and then observed for hydrolysis circles. Extract the plasmid th...

Embodiment 3

[0114] Example 3 Cellulase optimization construct activity research

[0115] The steps of producing heat-resistant recombinant protein with various engineering bacterial strains in Example 1 are similar. The original strains stored at -70°C were streak cultured on LB plates containing 50 μg / ml ampicillin, and cultured overnight at 37°C. A single colony was selected, inoculated in LB liquid medium containing 100 μg / ml ampicillin, and cultured with shaking at 37°C. When the OD600 of the bacterial solution concentration was between 0.4 and 0.7, isopropylthio-β-D-galactoside (IPTG) was added to a final concentration of 1 mM. After continuing to cultivate for 6 hours, the cells were collected by centrifugation, and the culture solution was discarded. The cells were uniformly dispersed in an appropriate amount of 100 mM citrate solution with pH 5.0 by shaking. The suspended bacteria are lysed by ultrasonic waves (reference parameters are: ultrasonic instrument Sonifier 250 intens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com