Nanoparticle surface modified active semi-coke compound desulfurization denitrification agent and preparation method thereof

A technology for desulfurization, denitrification, and active semi-coke, which is applied in the coal chemical industry, can solve the problems of high operating cost, short service life, and no recovery economic value of desulfurized gypsum, and achieves simple comprehensive utilization, less desulfurization agent consumption, and good market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of CeO by dipping composite method 2 Nanoparticle-modified active semi-coke composite desulfurization and denitrification agent.

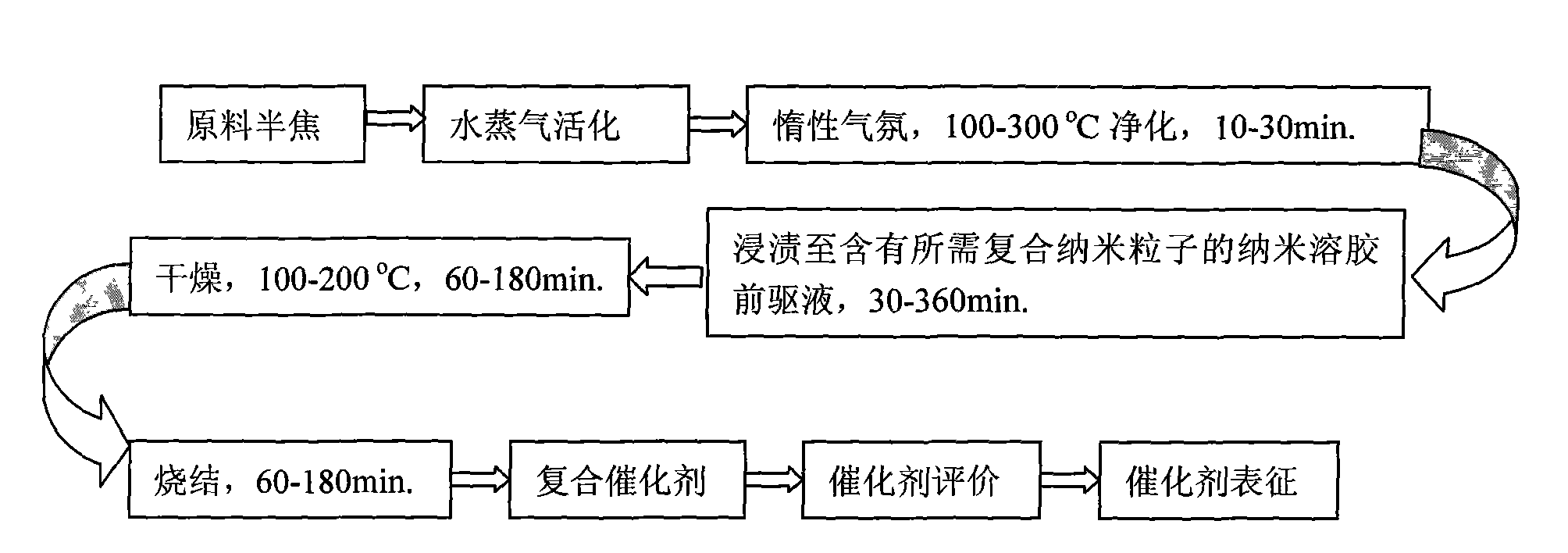

[0031] use figure 1 In the process shown, CeO is compounded on the surface of the active semi-coke using the dipping compound method. 2Nanoparticles.

[0032] The activated semi-coke produced by the steam activation method is a carbon-based material for desulfurization agent (purchased from Yankuang Group), and the activated semi-coke particles with a diameter of 5-15mm are selected and dried under an argon atmosphere at 150 ° C for 60 minutes to remove ash.

[0033] At the same time, CeO with a concentration of 0.4 mol / L was prepared by the sol-gel method 2 Nano sol precursor solution, wherein the dispersant is polyethylene glycol, and the pH is controlled between 4-5.

[0034] Immerse the purified activated semi-coke in CeO 2 Nanosol precursor solution for 360min.. After leaching, it was dried in a drying oven a...

Embodiment 2

[0043] Example 2 Preparation of Fe by hydrothermal growth method 2 O 3 and MnO 2 Activated semi-coke composite desulfurization and denitration agent modified on the surface of composite nanoparticles.

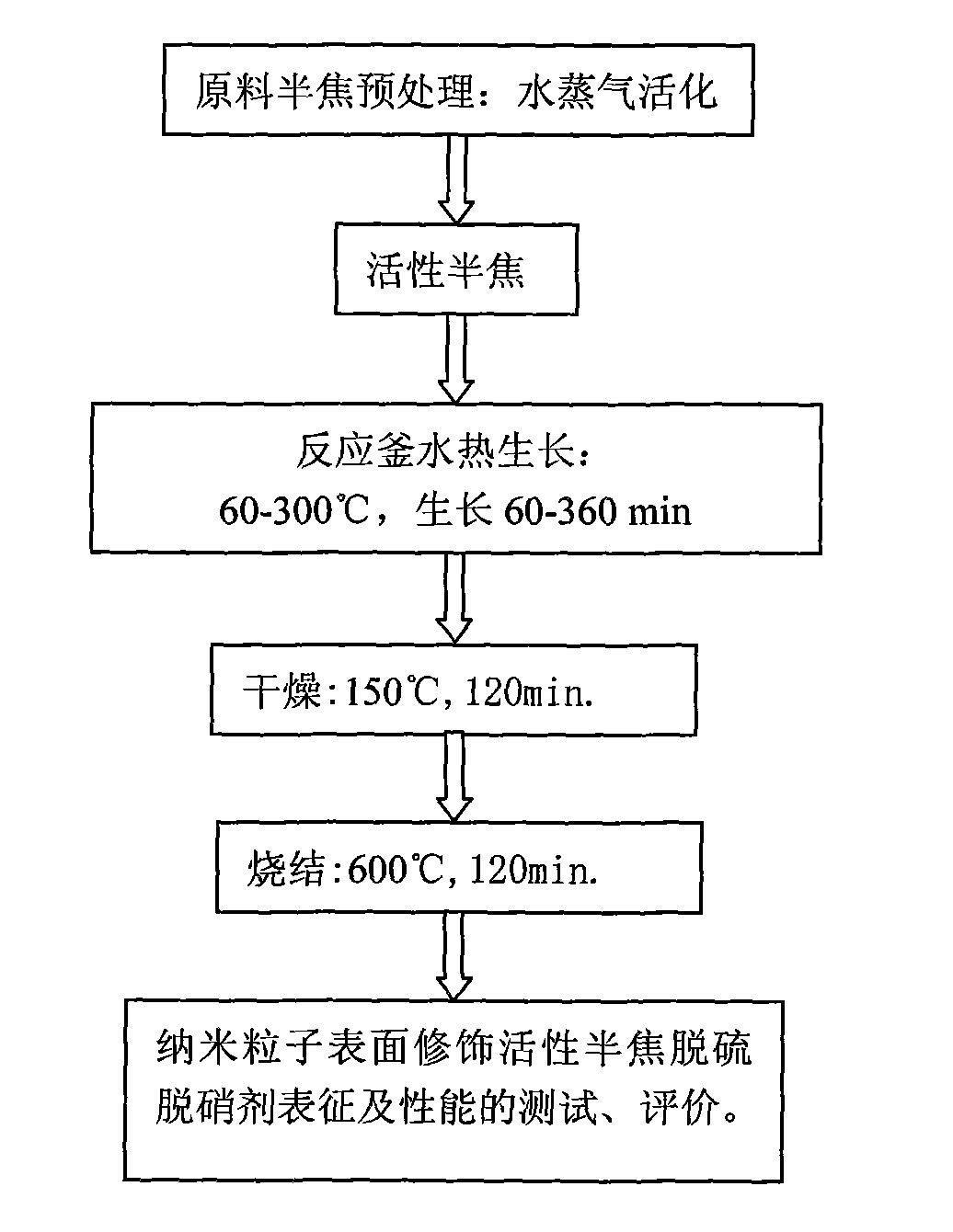

[0044] according to figure 2 The shown process, using the hydrothermal growth method to modify Fe on the surface of the active semi-char 2 O 3 and MnO 2 composite nanoparticles.

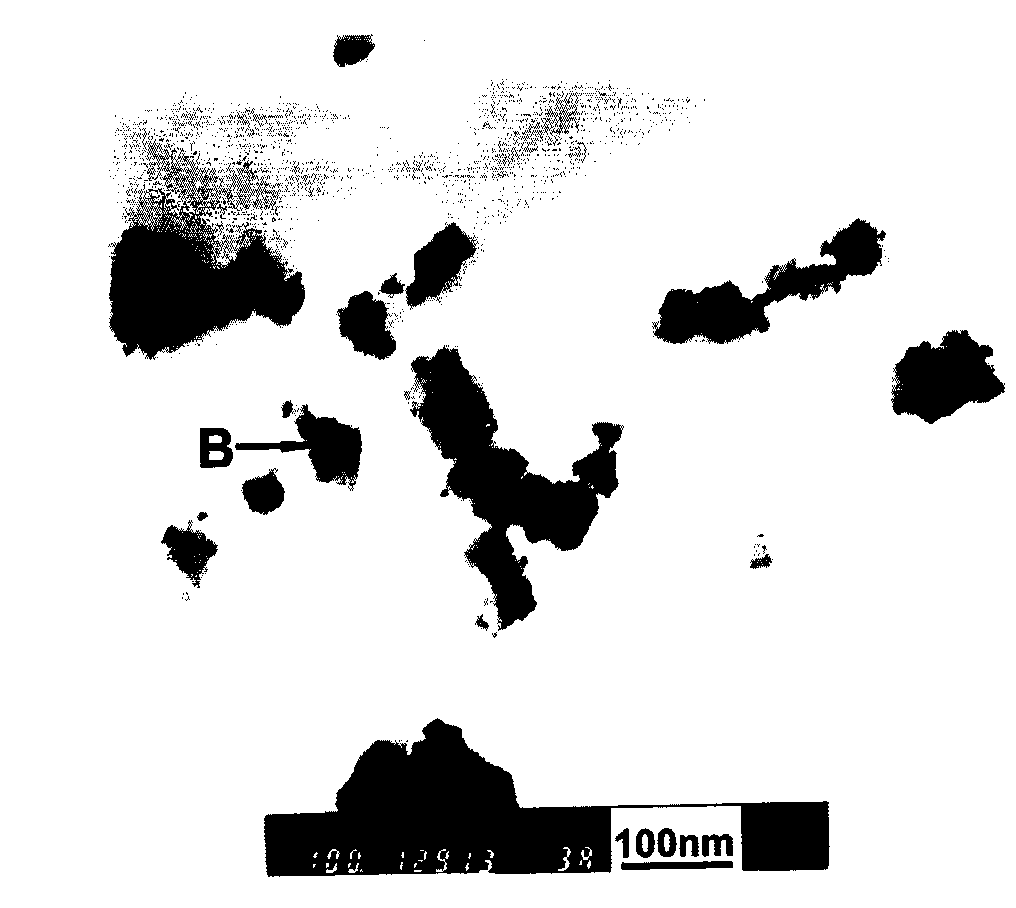

[0045] Purchase the active semi-coke particles produced by the water vapor activation method with a diameter of 5-15mm, and then immerse the active semi-coke in the MnSO containing the volume ratio of the active semi-coke and the nano-sol precursor liquid at a ratio of 1:3. 4 , KMnO 4 and FeCl 3 In the hydrothermal kettle of the mixed solution, the concentrations of the three are respectively: 0.006mol / L, 0.004mol / L, 0.005mol / L, and polyethylene glycol is used as a dispersant. The pH of the solution was adjusted to 8, the growth temperature was controlled to 140 °C, and the temperature was m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com