Supported titanium dioxide photocatalyst and preparation method thereof

A photocatalyst and load-type technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the specific surface area cannot be effectively improved, affecting the treatment efficiency of photocatalysts, and unfavorable enrichment of organic molecules and other problems, to achieve the effect of increasing the chance of contact reaction, eliminating pollution, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

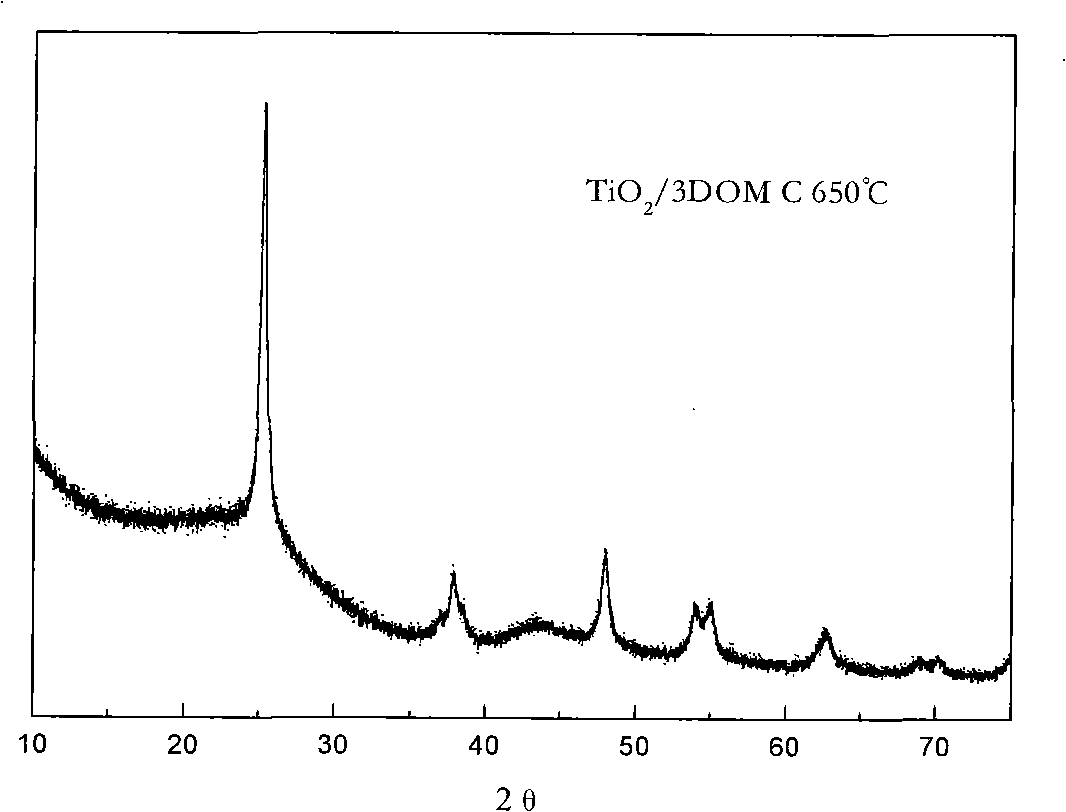

[0031] Example 1 takes monodisperse SiO 2 Microspheres

[0032] Pour a certain amount of ethyl orthosilicate into the Erlenmeyer flask containing the mixture of ammonia water and absolute ethanol at one time, wherein the concentration of ethyl orthosilicate is 0.45mol / L, and the concentration of ammonia water is 2.2mol / L . The reaction flask was placed in a constant temperature water bath at 25° C. with magnetic stirring, and the reaction was carried out for 10 hours. The particle size of the obtained silica is about 530m. Using absolute ethanol as a solvent, the reaction mother liquor is subjected to centrifugation-ultrasonic dispersion and repeatedly washed several times, and finally, the silicon dioxide microspheres are ultrasonically dispersed in absolute ethanol with a content of 5w% for further use.

[0033] In the same way, SiO with different diameters can be synthesized by changing the concentration of each reagent. 2 Microspheres. Some synthesis results are sho...

Embodiment 2

[0036] Embodiment 2 prepares monodisperse SiO with microemulsion method 2 Microspheres

[0037] The microemulsion system is composed of cetyltrimethylammonium chloride / cyclohexane / water. Add 11mL tetraethyl orthosilicate dropwise at 30°C at a rate of 0.2mL / min. After the dropwise addition, continue to stir for 1 hour, and then add concentrated ammonia water. Clear and transparent; after continuing to react for a certain period of time, the system appeared white turbidity again, indicating that the hydrolysis and condensation reaction of tetraethylorthosilicate began to proceed. The reactor was sealed and stirring was continued for 10 hours. The obtained silica microspheres were about 40 in diameter. After the reaction mother liquor is flocculated with acetone, it is washed several times by centrifugation-ultrasonic dispersion with absolute ethanol as a solvent, and finally, the silicon dioxide microspheres are ultrasonically dispersed in absolute ethanol with a content of 5...

Embodiment 3

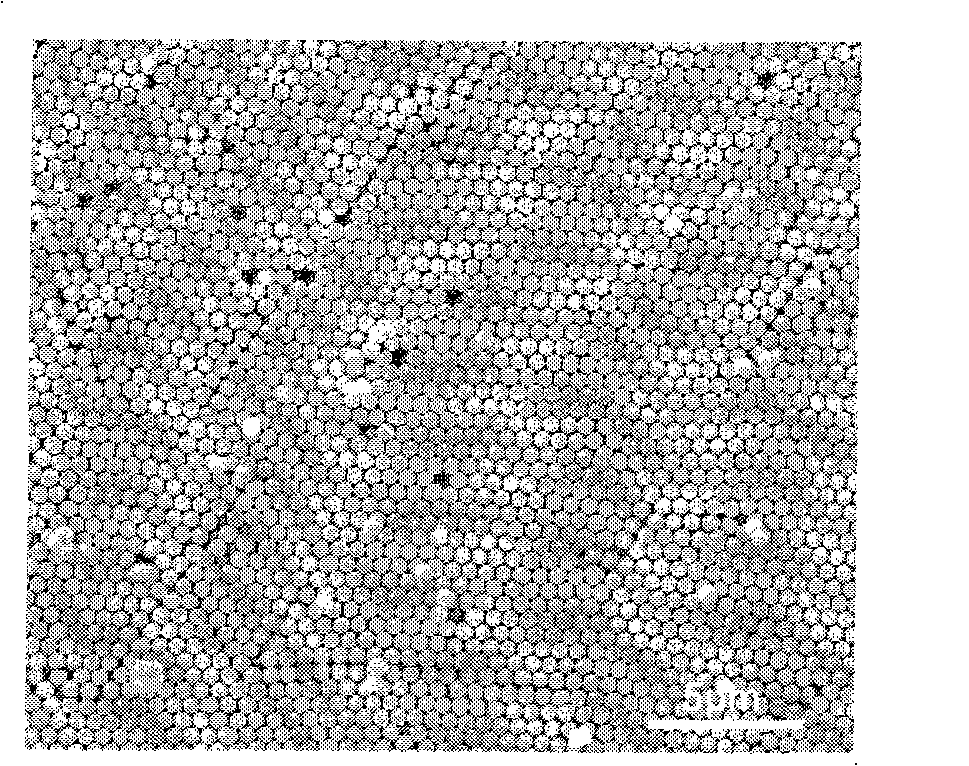

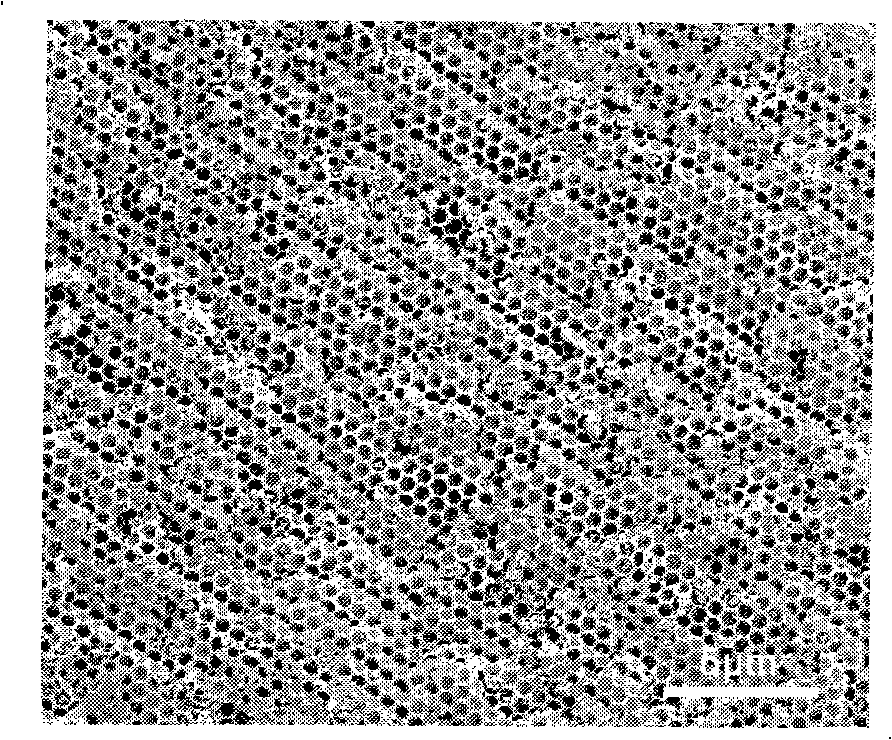

[0041] Example 3 SiO 2 Assembly of templates

[0042] SiO 2 Template assembly and sintering treatment. 1) When assembling by gravity deposition method, measure 30mL SiO 2 The microsphere suspension was placed in a 40mL flat-bottomed sedimentation tank and naturally settled at room temperature. The deposition should be carried out on a stable experimental bench, while avoiding excessive noise, so as to prevent external factors such as vibration and sound from disturbing the sedimentation process of the microspheres. When white SiO 2 When the liquid layer basically drops to the bottom of the sedimentation tank, use a syringe to draw out the upper layer to clear the night, then seal the opening of the sedimentation tank with a plastic film, pierce a few small holes on the film, and let it stand and dry for 10 days at room temperature to obtain a large area with a thickness of about 1mm. SiO 2 colloidal crystals. 2) When assembled by centrifugation, measure 20mL SiO 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com