Preparation method of Nd-YVO4 transparent laser ceramic material

A technology for laser ceramics and laser materials, applied in the field of material metallurgy, can solve the problems of difficult to increase the doping concentration of single crystal materials, low manufacturing cycle and cost, difficult preparation, etc., and achieve easy control of process flow, wide application range, and raw material preparation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

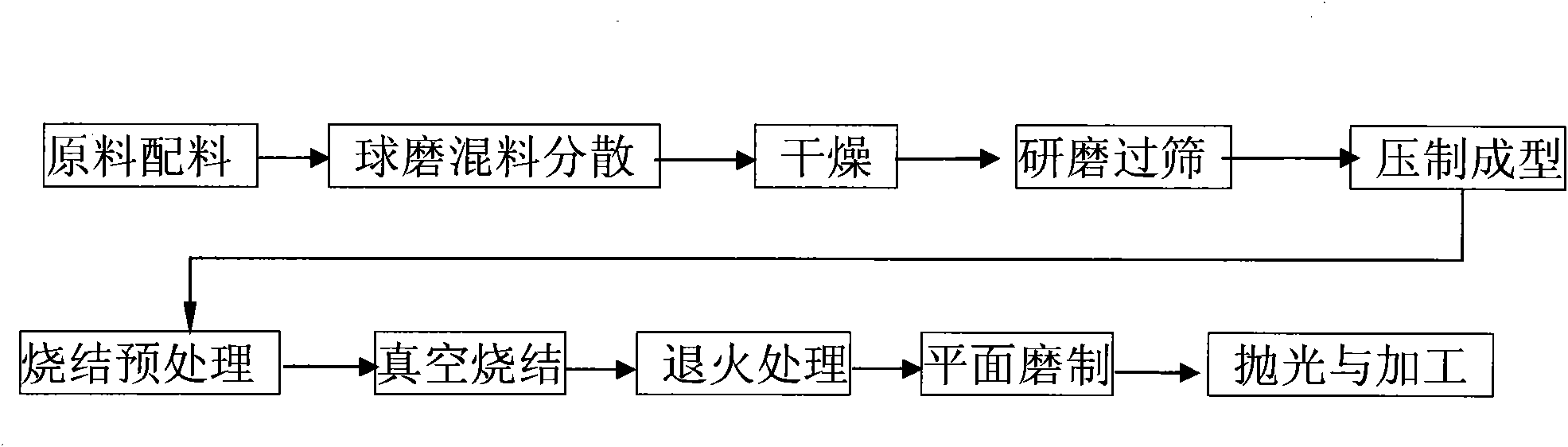

Method used

Image

Examples

Embodiment 1

[0020] Prepare yttrium oxide (Y 2 o 3 ) powder and vanadium oxide (V 2 o 5 ) powder, adding a total of 2% neodymium oxide (Nd 2 o 3 ) powder (molar percentage), the magnesium oxide (MgO) powder (molar percentage) of 0.01% of the total amount, 0.01% (mass percentage) of the total amount of high-purity TEOS, put into the polytetrafluoroethylene ball mill tank, add dehydrated alcohol And corundum ceramic balls, rotating speed 800rad / min, ball milling for 6 hours. Take it out and dry it in an oven, grind it through a 200-mesh sieve. Use a 100MPa pressure shaft to pressurize in one direction, press it into a disc with a diameter of 12-18mm, and press it further in a cold isostatic pressing device with a pressure of 300MPa. Put into vacuum sintering furnace for pretreatment, vacuum degree 10 -3 Pa, the pretreatment temperature is 800 degrees, and the holding time is 5 hours. On the basis of pretreatment, further vacuumize, the vacuum degree is less than 10 -3 Pa, the heatin...

Embodiment 2

[0022] Preparation of YVO by wet chemical method 4 powder and neodymium oxide (Nd 2 o 3 ) powder, sodium oxide (Na 2 (O) a mixture of powders, wherein the neodymium oxide content is 3% (mol percent) of the total amount, sodium oxide (Na 2 O) powder content (molar percentage) is 0.005% of total amount, adds 0.01% (mass percentage) high-purity TEOS of total amount, puts into polytetrafluoroethylene ball mill jar, adds dehydrated alcohol and corundum ceramic ball, rotating speed 1000rad / min, ball mill 8 hours. Take it out and evaporate it to dryness with an evaporator, and grind it through a 200-mesh sieve. Use a pressure axis of 100MPa to pressurize in one direction, and further press in a cold isostatic pressing device with a pressure of 400MPa. Put into vacuum sintering furnace for pretreatment, vacuum degree 10 -3 Pa, the pretreatment temperature is 900 degrees, and the holding time is 6 hours. On the basis of pretreatment, further vacuumize, the vacuum degree is less...

Embodiment 3

[0024] Yttrium oxide (Yttria) was prepared by wet chemical method 2 o 3 ) powder, neodymium oxide (Nd 2 o 3 ) powder, magnesium oxide (MgO) powder and vanadium oxide (V 2 o 5 ) powder mixture, in which yttrium oxide (Y 2 o 3 ) powder and vanadium oxide (V 2 o 5 ) in a molar ratio of 1:1, the neodymium oxide content is 5% (molar percentage) of the total amount, the magnesium oxide (MgO) content (molar percentage) is 0.005% of the total amount, and 0.015% (mass percentage) of the total amount is added ) of high-purity TEOS was put into a polytetrafluoroethylene ball mill jar, adding absolute ethanol and corundum ceramic balls, and ball milled for 16 hours at a speed of 1200 rad / min. Take it out and evaporate it to dryness with an evaporator, and grind it through a 200-mesh sieve. Use a 100MPa pressure shaft to pressurize in one direction, and further press in a cold isostatic pressing device with a pressure of 350MPa. Put into vacuum sintering furnace for pretreatment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com