Method for extracting succinic acid from succinic acid fermentation liquor

A technology of succinic acid and fermentation broth, applied in the separation/purification of carboxylic acid compounds, ammonium sulfate, organic chemistry, etc., can solve the problems of high operating cost, complex process, high energy consumption, and achieve low consumption of raw and auxiliary materials , The effect of simple process operation and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

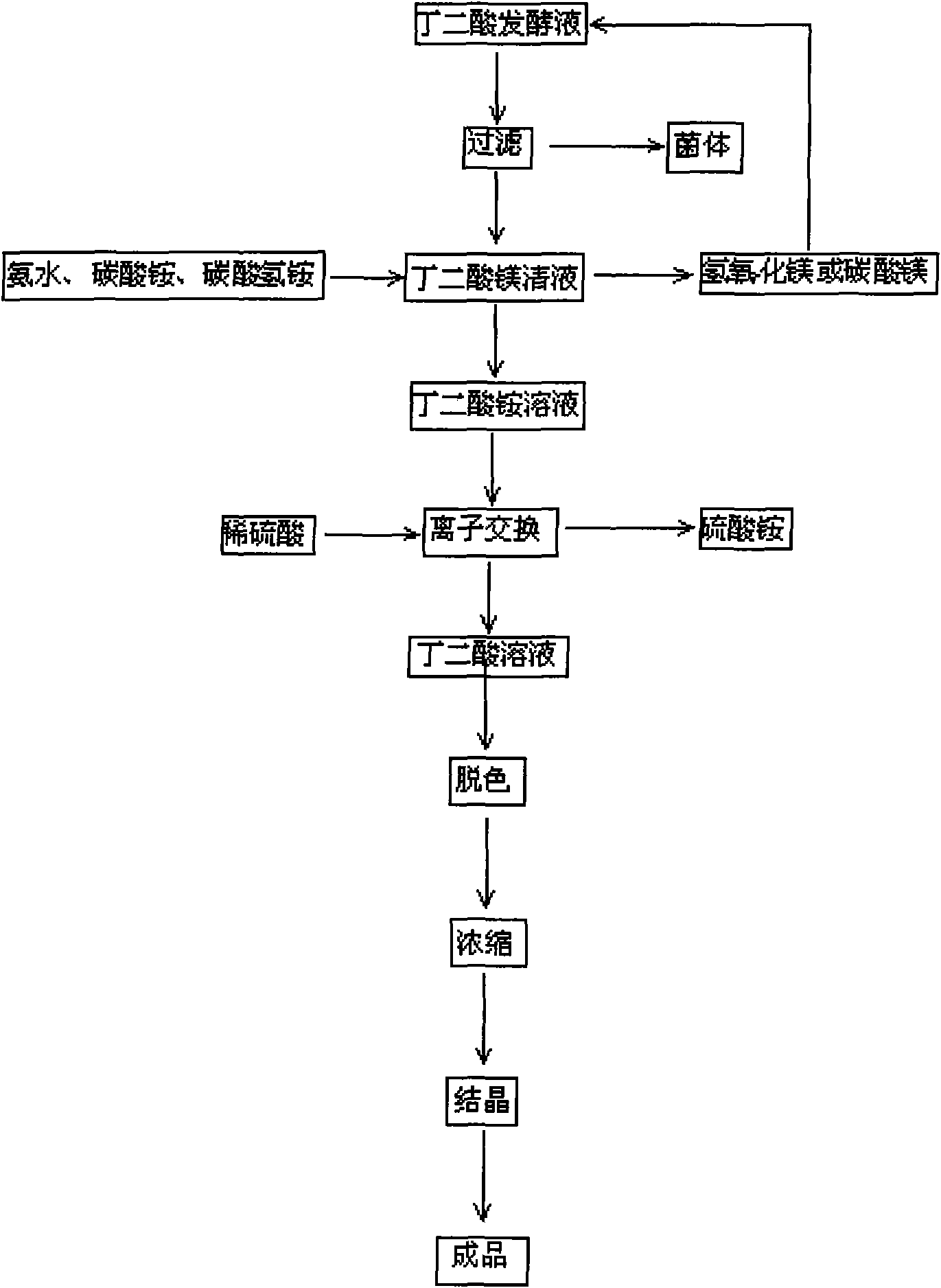

Method used

Image

Examples

Embodiment 1

[0025] The succinic acid fermentation liquid is obtained through the anaerobic fermentation of the carbohydrate by microorganisms.

[0026] Add 0.9 g of flocculant polyacrylamide to 30 L of succinic acid fermentation broth, stir at 85°C for 30 minutes, and centrifuge to obtain filtrate—magnesium succinate fermentation serum. Slowly add ammonia solution with a mass volume ratio (g / 100ml) of 17% to 35L of magnesium succinate fermentation supernatant with a concentration of 5.6% (g / 100ml), the addition amount is 2.8L, keep it for 1 hour, centrifuge Separate and wash the filter cake with a little water. The obtained magnesium hydroxide can be used for succinic acid fermentation.

[0027] The ammonium succinate solution obtained after centrifugation was 35.6L, which was pumped into the 001×7 cation exchange column at a flow rate of 1.5BV / h, and the effluent was succinic acid solution. (g / 100ml) dilute sulfuric acid solution for regeneration, and the regeneration solution is ammon...

Embodiment 2

[0030] The succinic acid fermentation liquid is obtained through the anaerobic fermentation of the carbohydrate by microorganisms.

[0031] Add 0.9 g of flocculant polyacrylamide to 30 L of succinic acid fermentation broth, stir at 85° C. for 20 minutes, and centrifuge to obtain magnesium succinate fermentation supernatant. Slowly add 30% (g / 100ml) of ammonium carbonate aqueous solution to 35L of magnesium succinate fermented supernatant liquid with a concentration of 5.8% (g / 100ml). Wash the filter cake with a small amount of water. The resulting magnesium carbonate is used for succinic acid fermentation.

[0032] 37.1 L of ammonium succinate solution obtained after centrifugation was pumped into a 001×7 cation exchange column at a flow rate of 1.5 BV / h, and the effluent was succinic acid solution. After rinsing the separation column with a small amount of water, it is regenerated with 4% dilute sulfuric acid solution, and the regenerated solution is ammonium sulfate soluti...

Embodiment 3

[0035] The succinic acid fermentation liquid is obtained through the anaerobic fermentation of the carbohydrate by microorganisms.

[0036] 30 L of succinic acid fermentation broth was filtered at 70° C. using a membrane with a pore size of 0.05 μm to obtain magnesium succinate fermentation serum. Slowly add 30% ammonium bicarbonate aqueous solution into 36L concentration of magnesium succinate fermented supernatant liquid of 5.4% (g / 100ml), its addition is 7.8L, keep 1 hour, centrifuge, and wash filter with a small amount of water cake. The resulting magnesium carbonate is used for succinic acid fermentation.

[0037] 40.8L of ammonium succinate solution obtained after centrifugation was pumped into a 001×7 cation exchange column at a flow rate of 1.5BV / h, and the effluent was succinic acid solution. After rinsing the separation column with a small amount of water, it is regenerated with 4% dilute sulfuric acid solution, and the regenerated solution is ammonium sulfate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com