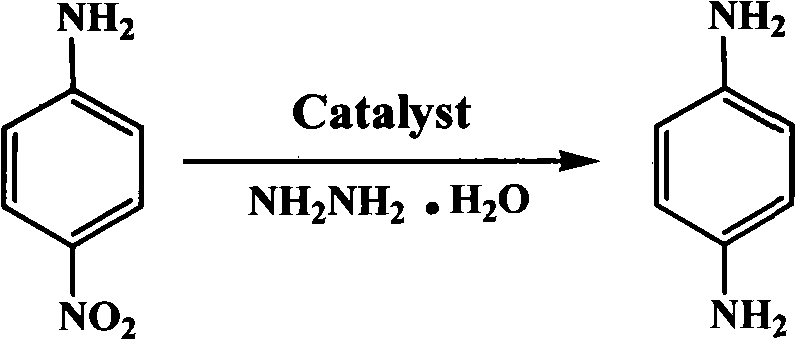

Synthesis method of p-phenylenediame

A synthesis method and technology for p-phenylenediamine, which are applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of low total product yield, three-waste pollution, and low selectivity, and achieve product purity. Good, less environmental pollution, high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a 500mL three-necked flask, add 138g (1 mole) of p-nitroaniline, 300ml of ethanol, and 0.1 mole of a magnetic solid base catalyst, stir and heat to dissolve p-nitroaniline, raise the temperature to 50°C, and slowly add 96g of hydrazine hydrate dropwise (3 moles), after dropping for 1 hour, heat preservation reaction for 5 hours, filter while hot, add 500ml water, adjust the solution to be alkaline, then leave standstill, separate out white crystal p-phenylenediamine 82g, productive rate is 76%.

[0019] Product melting point: 138-140°C, purity 98% (HPLC analysis conditions: chromatographic column C18, Φ4.0×200mm, column temperature 30°C, mobile phase 30% methanol-70% 0.02M phosphate buffer). IR(KBr)cm -1 : 3450, 3400, 3205, 1640, 1520, 1270.

Embodiment 2

[0021] In a 500mL three-necked flask, add 138g (1 mole) of p-nitroaniline, 300mL of ethanol, and 0.05 mole of magnetic solid base catalyst, stir and heat to dissolve p-nitroaniline, raise the temperature to 100°C, and slowly add 64g of hydrazine hydrate dropwise (2 moles), after dropping for 1 hour, heat preservation reaction for 10 hours, filter while hot, add 500mL water, adjust the solution to be alkaline, leave standstill, separate out white crystal p-phenylenediamine 76g, yield rate is 70%.

Embodiment 3

[0023] In a 500mL three-necked flask, add 138g (1 mole) of p-nitroaniline, 300mL of ethanol, and 0.01 mole of a magnetic solid base catalyst, stir and heat to dissolve p-nitroaniline, raise the temperature to 50°C, and slowly add 320g of hydrazine hydrate dropwise (10 moles), after dropping for 1 hour, heat preservation reaction for 20 hours, filter while hot, add 500mL water, adjust the solution to be alkaline, leave standstill, separate out white crystal p-phenylenediamine 81g, yield rate is 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com