Luminol selective detect sensor and manufacture method thereof

A detection sensor and selective technology, which is applied in the direction of chemical reaction of materials for analysis, chemiluminescence/bioluminescence, etc., can solve problems such as short life, complicated doping methods, and harsh conditions for hot electron generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The invention provides a kind of preparation method of luminol selective detection sensor, it is characterized in that comprising the following steps:

[0013] (1), after the surface of the high-purity titanium wire is pretreated to remove the surface oxide film, vacuum drying is carried out at room temperature;

[0014] (2), using N,N'-dimethylformamide that completely removes water as the electrolyte to anodize the dried titanium wire for 3 to 10 minutes;

[0015] (3), take out the oxidized titanium wire, and carry out vacuum drying.

[0016] The electrolysis voltage in the step (2) will be quickly added to between 30~35V.

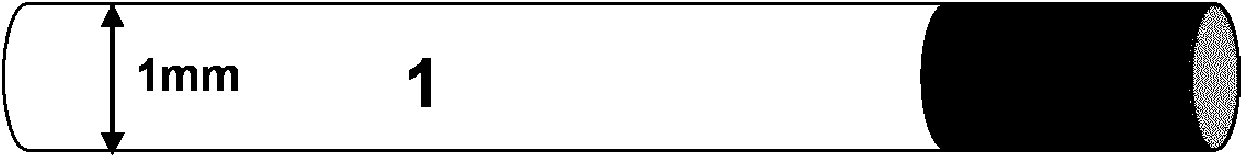

[0017] Such as figure 1 As shown, the present invention further provides a luminol selective detection sensor, which is characterized in that it includes a high-purity titanium substrate 1 and a layer of carbon-doped titanium oxide film 2, and is characterized in that: the carbon-doped oxide The titanium film 2 is grown directly on the high-pur...

Embodiment 2

[0021] A titanium wire with a diameter of 0.1 cm and a purity of 99% was cut into 6 cm long, and a section was polished on a water-milled gauze, and was ultrasonically cleaned with acetone and absolute ethanol for 10 minutes to remove surface oil, and then mixed with acid (V HF :V HNO3 :V H2O =1:4:5) cleaning to remove the oxide film on the surface of the titanium wire. Finally, in DMF, the platinum wire is used as the auxiliary cathode, the titanium wire is used as the anode, and oxidized at a constant voltage of 32V for 5 minutes, that is, a layer of yellow carbon-doped oxide film is obtained on the surface of the titanium wire. XPS is used to characterize the existence of doped carbon atoms to replace the oxygen in titanium oxide. This preparation method is simpler and faster than that reported in the literature, and its stability is more than half a year; The BR buffer of =9 was scanned by cyclic voltammetry, and thermionic electrons were generated at about -1V, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com