Preparation method of nano mesoporous titania with core-shell structure

A nano-mesoporous, core-shell structure technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of large particles, non-uniformity, single crystal structure of mesoporous titanium oxide, etc., to achieve large specific surface area and raw material cost. Low, uniform aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

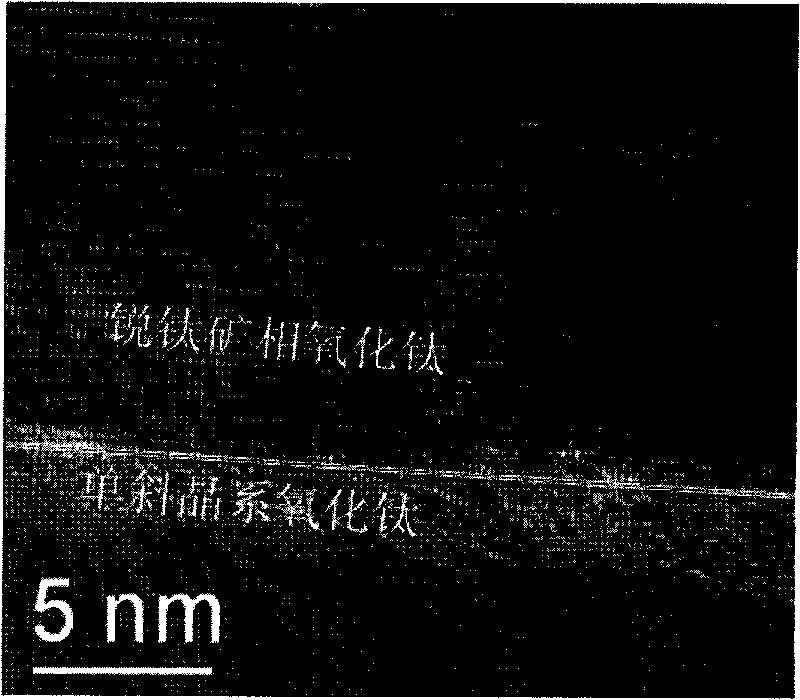

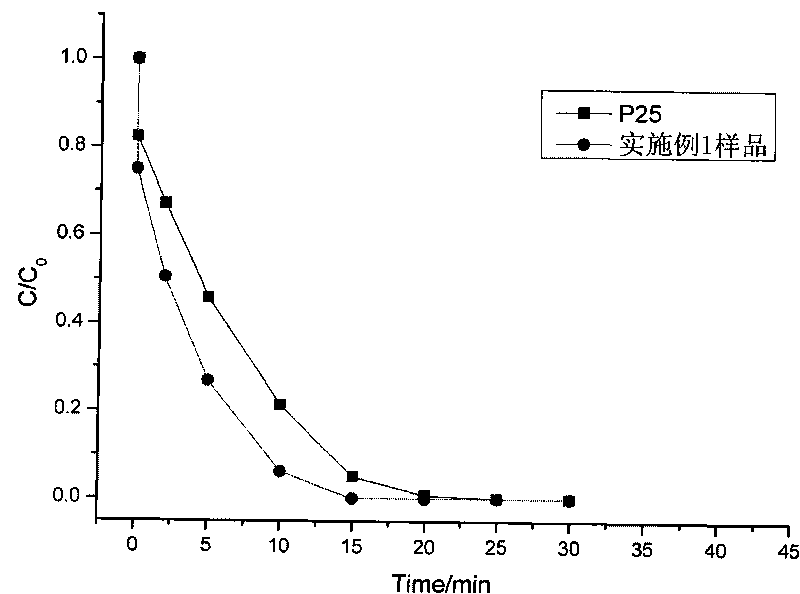

[0020] Use sodium trititanate as raw material, add 4% sodium dodecyl sulfate by mass, and obtain a powder with a particle size of 50-1000 nanometers after high-energy crushing; add water twice the mass of the powder, and heat React under ambient conditions for 24 hours; add hydrochloric acid solution, adjust pH = 1, then filter, wash, dry, and heat treat at 400°C for 2 hours to obtain nanometer mesoporous titanium oxide powder with core-shell structure, in which the core is sharp Titanium ore type titanium oxide, the shell is monoclinic titanium oxide, the specific surface area is 180m 2 / g, the pore volume is 0.28cm 3 / g, the most probable pore diameter is 11nm. The product that obtains and P25 titanium oxide (Degussa) adopt ultraviolet photodegradation methyl orange experiment respectively, the result sees image 3 , the experiment proves that the rate of explaining the product of the present invention is greater than that of P25, and its activity is higher than that of P2...

Embodiment 2

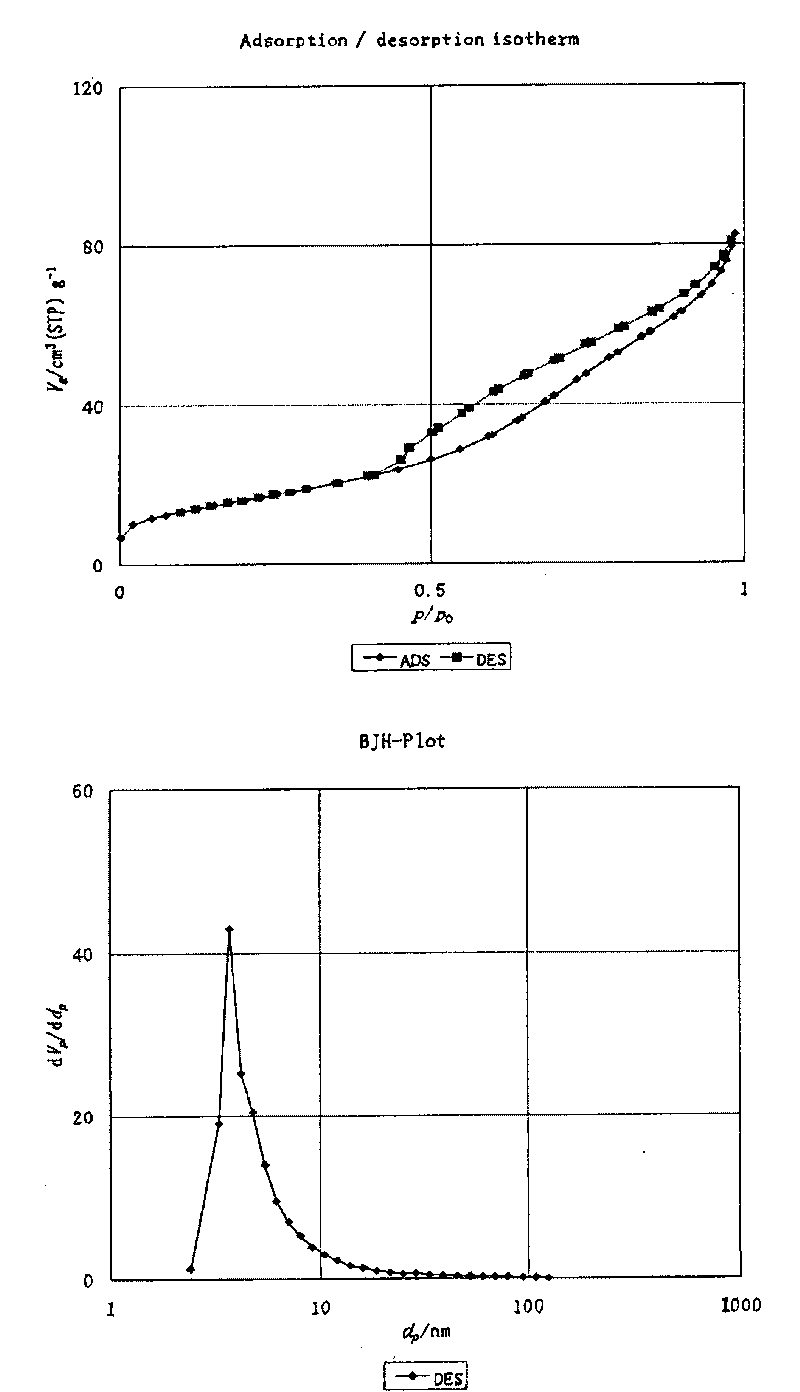

[0022] Using potassium dititanate as raw material, add 0.1% titanate coupling agent by mass, and obtain a powder with a particle size of 50-1000 nanometers after high-energy crushing; add water 3.5 times the mass of the powder, and heat React under ambient conditions for 4 hours; add sulfuric acid solution, adjust pH = 3, then filter, wash, dry, and heat treat at 200°C for 8 hours to obtain nanometer mesoporous titanium oxide powder with core-shell structure, in which the core is sharp Ilmenite-type titanium oxide, the shell is rutile-type titanium oxide, and the specific surface area is 130m 2 / g, the pore volume is 0.22cm 3 / g, the most probable pore diameter is 8nm. figure 2 The curve can prove that the product has a nanopore size.

Embodiment 3

[0024] Using potassium tetratitanate as raw material, add 5% polyethylene glycol by mass, and obtain a powder with a particle size of 50-1000 nanometers after high-energy crushing; React for 48 hours; add nitric acid solution, adjust pH = 0.5, then filter, wash, dry, and heat-treat at 800°C for 0.5 hours to obtain nanometer mesoporous titanium oxide powder with core-shell structure, in which the core is rutile oxide Titanium, the shell is anatase titanium oxide, the specific surface area is 202m 2 / g, the pore volume is 0.30cm 3 / g, the most probable pore size is 13nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com