Method for preparing hard polyvinyl chloride plastic toughening and reinforcing agent

A rigid polyvinyl chloride, toughening and reinforcing agent technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment and other directions, can solve the problem of insignificant toughening effect, reduced tensile strength, poor modification effect, etc. problem, to achieve the effect of no dust pollution, not easy to desorb, and complete modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

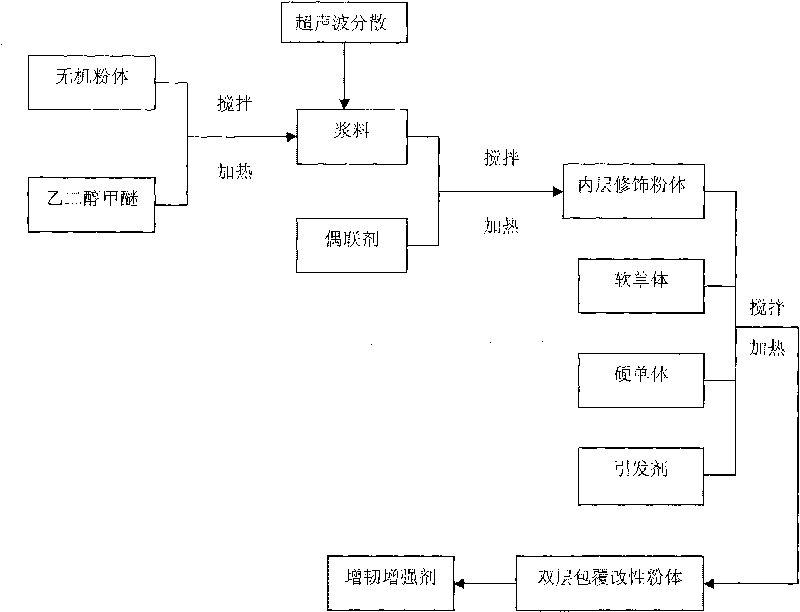

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is a preparation method of a toughening and strengthening agent for rigid polyvinyl chloride

[0026] a. Inorganic powder slurry preparation and ultrasonic assisted dispersion

[0027] Weigh 100g of 400-mesh calcium carbonate powder and 400g of ethylene glycol methyl ether solvent. Pour the mixed slurry into a three-necked flask. Heat in a water bath. The temperature of the water bath is 50°C. The stirring speed is 200 rpm and stirring for 10 minutes. Afterwards, move the three-necked flask into an ultrasonic container, continue to use a 50°C water bath for heating, and ultrasonically disperse for 15 minutes at an ultrasonic frequency of 2500 Hz to obtain a powder slurry.

[0028] b. Inorganic mineral powder coupling modification

[0029] After the powder slurry is obtained in the previous stage, the ultrasonic device is removed, and the vinyl triethoxy silane coupling agent with double bonds is gradually added dropwise to the three-necked flask. The amount of s...

Embodiment 2

[0035] a. Inorganic powder slurry preparation and ultrasonic assisted dispersion

[0036] Weigh 100g of 1250 mesh calcium carbonate powder, mix with 330g of ethylene glycol methyl ether solvent, pour the mixed slurry of the two into a three-necked flask, heat in a water bath, the temperature of the water bath is 65℃, the stirring speed is 300 rpm, stirring for 30 minutes After that, move the three-necked flask into an ultrasonic container, continue to use 65 ℃ water bath heating while ultrasonic dispersion for 30 minutes, the ultrasonic frequency is 2000 Hz, the powder slurry can be obtained.

[0037] b. Inorganic mineral powder coupling modification

[0038] After the powder slurry is obtained in the previous stage, the ultrasonic device is removed, and the vinyl trimethoxysilane coupling agent with double bonds is gradually added dropwise to the three-necked flask. The amount of silane coupling agent is 1g. The temperature of the control system is 80°C, the stirring speed is 400 r...

Embodiment 3

[0044] a. Inorganic powder slurry preparation and ultrasonic assisted dispersion

[0045] Weigh 100g of 2500 mesh calcium carbonate powder and 400g of ethylene glycol methyl ether solvent. Pour the mixed slurry into a three-necked flask, heat in a water bath, the temperature of the water bath is 50℃, stirring speed 300 rpm, stirring for 15 minutes Afterwards, move the three-necked flask into an ultrasonic container, continue to use a 50°C water bath for heating, and ultrasonically disperse for 30 minutes at an ultrasonic frequency of 2500 Hz to obtain a powder slurry.

[0046] b. Inorganic mineral powder coupling modification

[0047] After the powder slurry is obtained in the previous stage, the ultrasonic device is removed, and the vinyltrimethoxysilane coupling agent with double bonds is gradually added dropwise to the three-necked flask. The amount of silane coupling agent is 1.0g. The temperature of the system is controlled at 70°C, the stirring speed is 300 rpm, and the time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com