Method for producing R-mandelic acid with biocatalysis and separating and coupling method

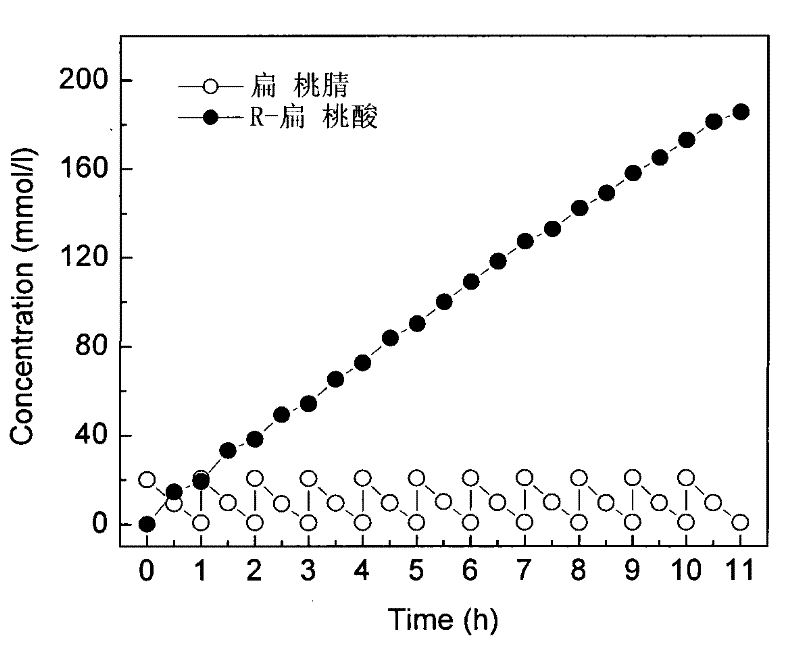

A biocatalysis, mandelic acid technology, applied in biochemical equipment and methods, microorganism-based methods, separation/purification of carboxylic acid compounds, etc., can solve the problems of batch decline, low cumulative product concentration, etc., and achieve catalytic yield The effect of improving, de-inhibiting, good prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Cultivation of Cells Containing Nitrilase

[0042] The composition of the final concentration of the seed medium: ammonium acetate 10g / L, yeast extract 6g / L, dipotassium hydrogen phosphate 5g / L, sodium chloride 1g / L, magnesium sulfate 0.2g / L, and the solvent is water. The CCTCC No: M 208168 strain was inoculated into the seed medium and cultured at 30°C for 28 hours to obtain the seed solution.

[0043] Final concentration composition of enzyme-producing fermentation medium: ammonium acetate 12.14g / L, yeast extract 7.79g / L, n-butyronitrile 3.29g / L, dipotassium hydrogen phosphate 5g / L, sodium chloride 1g / L, magnesium sulfate 0.2g / L, the solvent is water.

[0044] The seed solution was transferred to the above-mentioned fermentation medium with an inoculation amount of 6% (v / v), and the liquid content in a 15L fermenter was 8L. The culture temperature is 30° C., the rotation speed is 150 rpm, and the ventilation volume is 0.4 vvm. Cultivate for 20 hours and...

Embodiment 2

[0045] Example 2: Effect of different resin types on the catalytic yield of the catalyst.

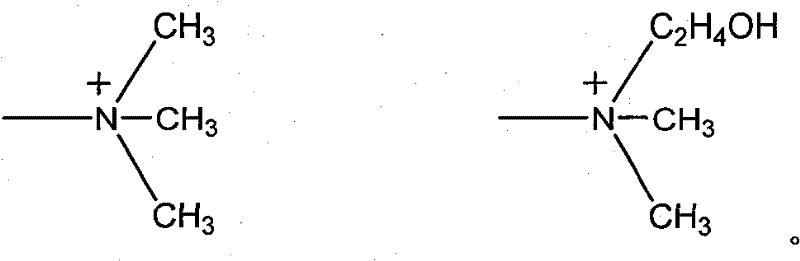

[0046] Pretreatment of anionic resin: first wash with water to remove pigment and impurities, then soak with twice the volume of 1N HCl for 24 hours, wash with water until neutral, then soak with 1N NaOH for 24 hours, convert to OH type, wash with water until neutral, and use pumping The filter device is drained and set aside.

[0047] The concentration of wet bacteria added to the aqueous solution (adjusted with NaOH) of pH 8.0 was 5g / l, the substrate concentration was 20mM, and then 20g / L of different resins (purchased from Shanghai Huazhen Technology Co., Ltd.) , under the condition of 150rpm, the biocatalytic reaction was carried out for 1h. Measure the R-mandelic acid concentration and the ee value in the solution, and calculate the catalytic yield of the catalyst and the optical activity of its product, the results obtained are shown in the following table:

[0048] Res...

Embodiment 3

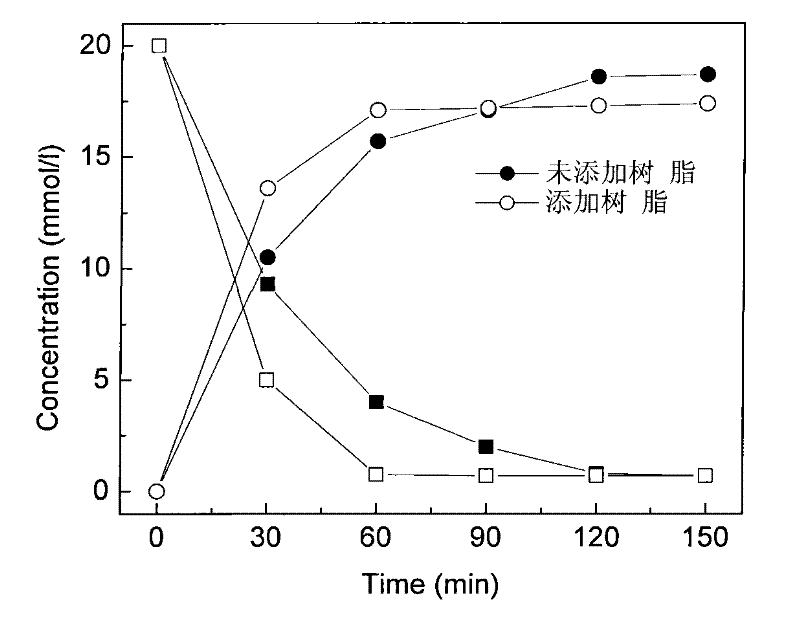

[0050] Embodiment 3: the influence of the catalytic yield of catalyst of different resin addition amount in conversion system

[0051] The concentration of wet bacteria added in the phosphate buffer solution of pH8.5 is 5g / l, and the substrate concentration is 20mM, then add 10, 20, 30, 40, 50g / L pretreated HZ202 wet resin respectively, in The reaction was carried out at 30° C. and 150 rpm, and samples were taken every 5 minutes to analyze the concentrations of products and substrates. Stop the reaction when the substrate is completely consumed and record the reaction time required for the conversion of the substrate. The results are shown in the following table:

[0052] Amount of added resin (g / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com