Method for preparing metal-phosphorus alloy hollow microsphere

A technology of hollow microspheres and hollow spheres, which is applied in the preparation of microspheres and microcapsule preparations, and can solve the problems of poor controllability of the shell thickness of alloy hollow microspheres, high cost of core template particles, and harsh conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

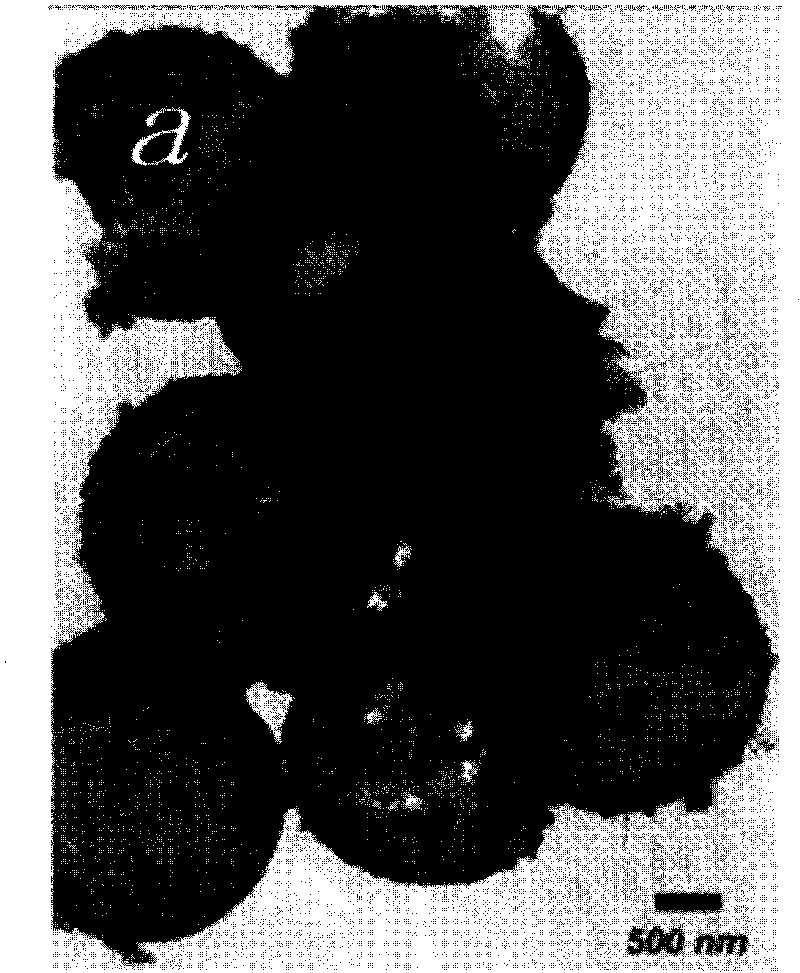

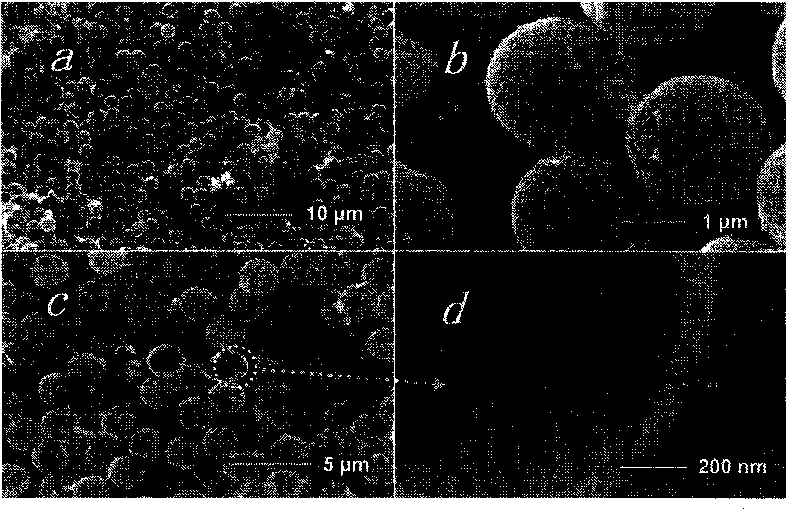

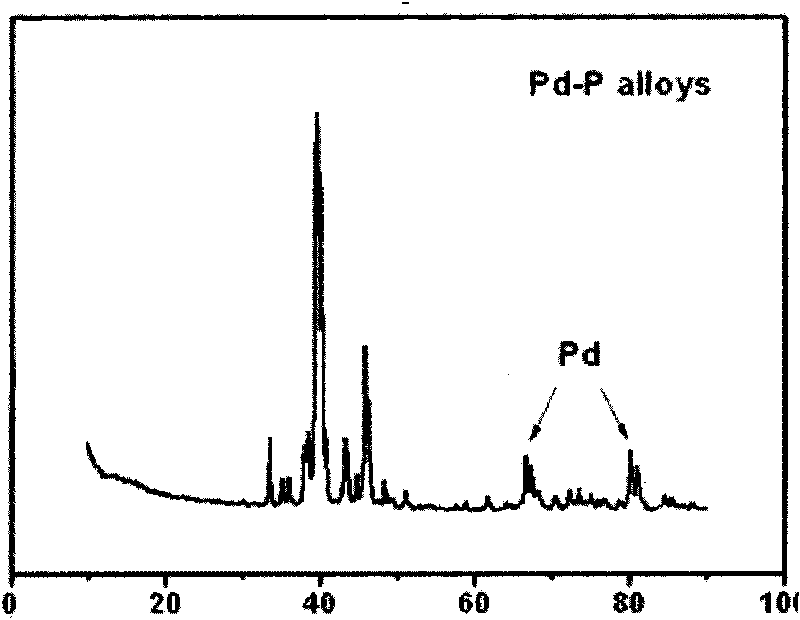

Image

Examples

Embodiment 1

[0043] Preparation of polystyrene microspheres:

[0044] Take 7.5ml of styrene, 0.5g of polyvinylpyrrolidone, 0.15g of azobisisobutyronitrile, and 17.5ml of ethanol, mix the above raw materials evenly, heat to 70°C and react for 15 hours to obtain polyphenylene with a particle size of 850nm to 1100nm. Ethylene microspheres.

Embodiment 2

[0046] Take 20g of stannous chloride hydrate and add it to 1000ml of hydrochloric acid solution with a concentration of 0.1M, stir, and ultrasonically treat the stannous chloride for 30 minutes to dissolve the stannous chloride, then add tin particles to the solution, and leave the solution for 3 days for aging get a sensitizer;

[0047] Soak 60 mg of polystyrene microspheres prepared in Example 1 into the sensitization solution, ultrasonically treat for 1 hour, then filter, and wash the filtrate with absolute ethanol to obtain sensitized polystyrene microspheres;

[0048] Take 0.001 mole of palladium chloride and dissolve it in 1000ml of hydrochloric acid solution with a concentration of 0.1M as an activation solution; get the sensitized polystyrene particles and add them to the activation solution, stir for 30 minutes to activate the polystyrene Styrene microspheres;

[0049] Weighing 200 mg of chloroplatinic acid, 1.5 g of sodium phosphite and 200 mg of ethylenediamine mon...

Embodiment 3

[0053] Take 20g of stannous chloride hydrate and add it to 1000ml of hydrochloric acid solution with a concentration of 0.1M, stir, and ultrasonically treat the stannous chloride for 30 minutes to dissolve the stannous chloride, then add tin particles to the solution, and leave the solution for 3 days for aging get a sensitizer;

[0054] Soak 60 mg of polystyrene microspheres prepared in Example 1 into the sensitization solution, ultrasonically treat for 1 hour, then filter, and wash the filtrate with absolute ethanol to obtain sensitized polystyrene microspheres;

[0055] Take 0.001 mole of palladium chloride and dissolve it in 1000ml of hydrochloric acid solution with a concentration of 0.1M as an activation solution; get the sensitized polystyrene particles and add them to the activation solution, stir for 30 minutes to activate the polystyrene Styrene microspheres;

[0056] Weighing 200 mg of palladium chloride, 3.0 g of sodium phosphite and 550 mg of ethylenediamine mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com