Method for producing hydrogen gas by methane-rich plasma

A plasma and methane-enriched technology, applied in chemical instruments and methods, hydrogen, climate sustainability, etc., can solve problems such as arc and system stable operation damage, poor preheating effect of raw material gas, and easy poisoning of catalysts, etc., to achieve improved Energy utilization efficiency, heat loss reduction, and life extension effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

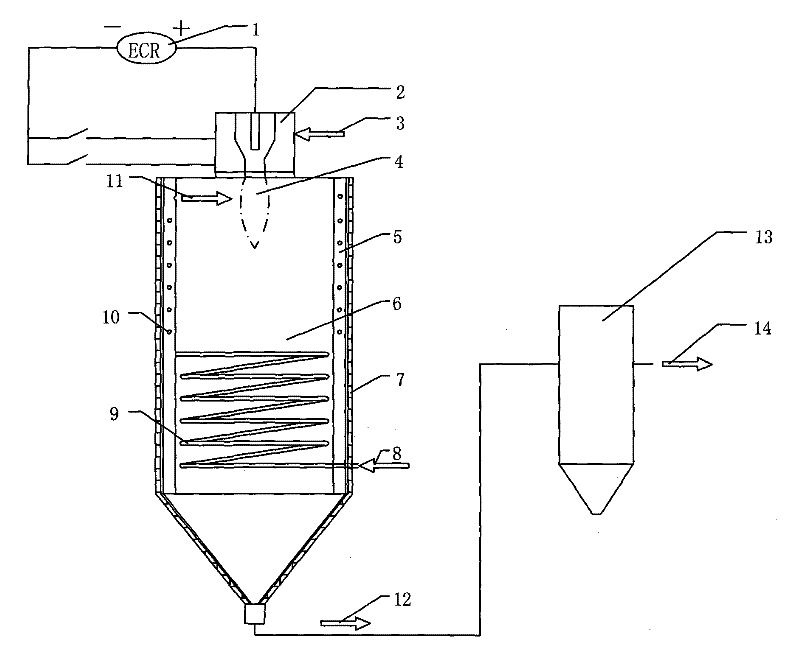

[0022] like figure 1When implementing the method for hydrogen production of the present invention, open the valve and send the natural gas 8 with a methane content of 98% into the heat exchanger 9 at the bottom of the plasma reactor, send the compressed hydrogen 3 to the plasma generator 2, and start the high The frequency ignition device ignites the arc of the plasma generator to form a plasma jet 4 . When the system reaches a steady state, the natural gas 8 entering the lower heat exchanger 9 of the plasma reactor 6 exchanges heat with the high-temperature hydrogen-rich gas after the plasma reaction, and the natural gas is heated to 300°C-600°C, and the heated natural gas continues to The spiral tube heat exchanger on the upper part of the plasma reactor 6 exchanges heat with the wall of the plasma reactor 6, the natural gas is heated and pre-activated for the second time, and the temperature rises to 600°C-900°C, and the preheated and activated natural gas 11 enters the pla...

Embodiment 2

[0025] like figure 1 , when implementing the hydrogen production method of the present invention, the valve is opened to allow the coal bed gas 8 with a methane content of 98% to enter the heat exchanger 9 at the lower part of the plasma reactor, and the compressed nitrogen gas 3 is sent to the plasma generator 2, and the high-frequency ignition is started The device ignites the plasma generator arc, forming a plasma jet 4 . When the system reaches a steady state, the coal bed gas entering the heat exchanger 9 at the lower part of the plasma reactor exchanges heat with the 900°C-1300°C gas after the plasma reaction, and the coal bed gas is heated to 300°C-600°C, and the heated coal bed The gas continues to exchange heat with the wall of the plasma reactor in the upper heat exchanger 10, the CBM is heated and pre-activated for the second time, and the temperature rises to 600°C-900°C, and the preheated and activated CBM 11 enters the plasma reactor 6, In the reaction zone, it ...

Embodiment 3

[0028] like figure 1 When implementing the method for hydrogen production of the present invention, the mixed gas 8 formed by mixing coke oven gas with a methane content of 26.3% and a hydrogen content of 55.6% with carbon dioxide enters the heat exchanger 9 at the bottom of the plasma reactor 6, and the The mixture of water vapor and oxygen is sent to the plasma generator 2 as the working gas 3, and the high-frequency ignition device is activated to ignite the arc of the plasma generator to form a plasma jet 4. When the system reaches a steady state, the mixed gas entering the lower heat exchanger of the plasma reactor 6 exchanges heat with the 1000°C-1500°C gas after the plasma reaction, the mixed gas is heated to 300°C-800°C, and the heated mixed gas The gas continues to exchange heat with the wall of the plasma reactor, the mixed gas is heated twice, and the temperature rises to 600°C-1000°C, the preheated and activated mixed gas 11 enters the plasma reactor, and generates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com