Preparation method of butenafine hydrochloride liniment

A technology of butenafine hydrochloride and nafine liniment, which is applied in the field of preparation of butenafine hydrochloride liniment, can solve the problems of severe skin irritation, long treatment course, unfavorable recovery of patients with skin allergies, etc., and achieve equipment energy consumption The condition is low, the dosage is reduced, and the effect of reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

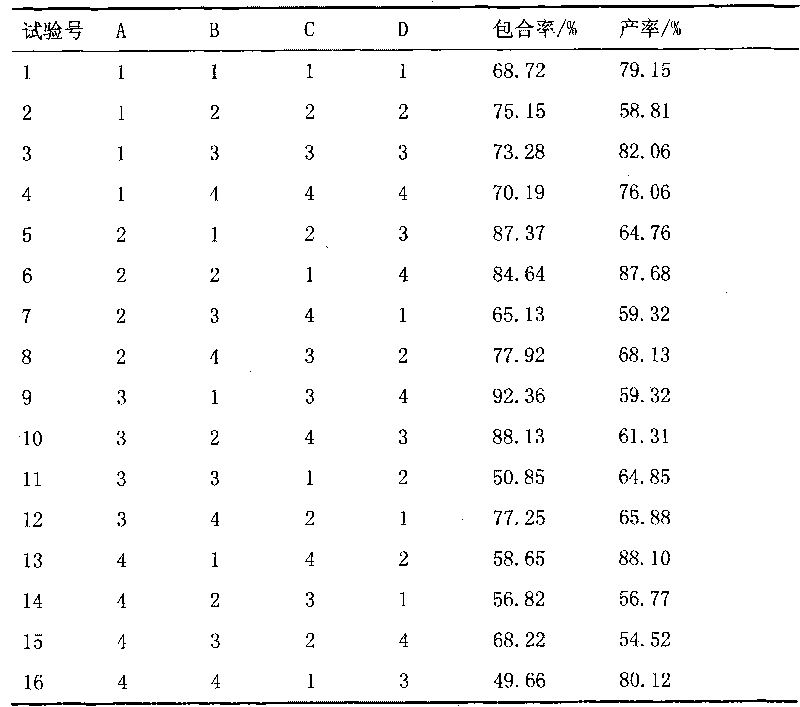

[0023] Example 1 Preparation of butenafine hydrochloride hydroxypropyl-β-cyclodextrin inclusion compound

[0024] 1. Instruments and reagents

[0025] DSC204 Thermal Analyzer (Netzsch, Germany); UV Spectrophotometer (Beijing Scientific Instrument Factory); Butenafine Hydrochloride Reference Substance (Shanghai Jiachen Chemical Co., Ltd.); Butenafine Hydrochloride API (Shanghai Jiachen Chemical Co., Ltd.) ; Hydroxypropyl-β-cyclodextrin (Zibo Qianhui Fine Chemical Co., Ltd.); other reagents were of analytical grade.

[0026] 2. Methods and Results

[0027] 2.1 Determination method of inclusion drug content

[0028] 2.1.1 Selection of UV detection wavelength

[0029] Accurately weigh butenafine hydrochloride reference substance 10.00mg and place it in a 10ml measuring bottle, dissolve it with methanol, after constant volume, get 1ml in a 10ml measuring bottle, use methanol solution (methanol: water=5:5) to constant volume, with Methanol solution was used as a blank control, a...

Embodiment 2

[0055] Embodiment 2 A kind of preparation method of butenafine hydrochloride liniment

[0056] Butenafine Hydrochloride Hydroxypropyl-β-Cyclodextrin Inclusion Compound 3.5g

[0057] Sodium Hyaluronate 0.2g

[0058] Urea 10g

[0059] Propylene glycol 10g

[0060] water up to 100g

[0061] Preparation:

[0062] Dissolve the clathrate in the prescribed amount in propylene glycol and water, then dissolve sodium hyaluronate and urea with appropriate amount of water respectively, add it to the clathrate solution, add water to a sufficient amount, and stir well to obtain the product.

Embodiment 3

[0064] Butenafine Hydrochloride Hydroxypropyl-β-Cyclodextrin Inclusion Compound 3.5g

[0065] Sodium Hyaluronate 0.2g

[0066] Urea 5g

[0067] Propylene glycol 10g

[0068] Benzalkonium Bromide 0.2

[0069] water up to 100g

[0070] Preparation:

[0071] Dissolve the clathrate in the prescribed amount in propylene glycol and water, then dissolve sodium hyaluronate and urea with appropriate amount of water respectively, add it to the clathrate solution, add water to a sufficient amount, and stir well to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com