Low-reflection optical interface layer and preparation method thereof

An optical interface, low-reflection technology, applied in optics, optical components, coatings, etc., can solve the problems of reducing the film forming temperature, changing the refractive index of the polymer substrate, deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

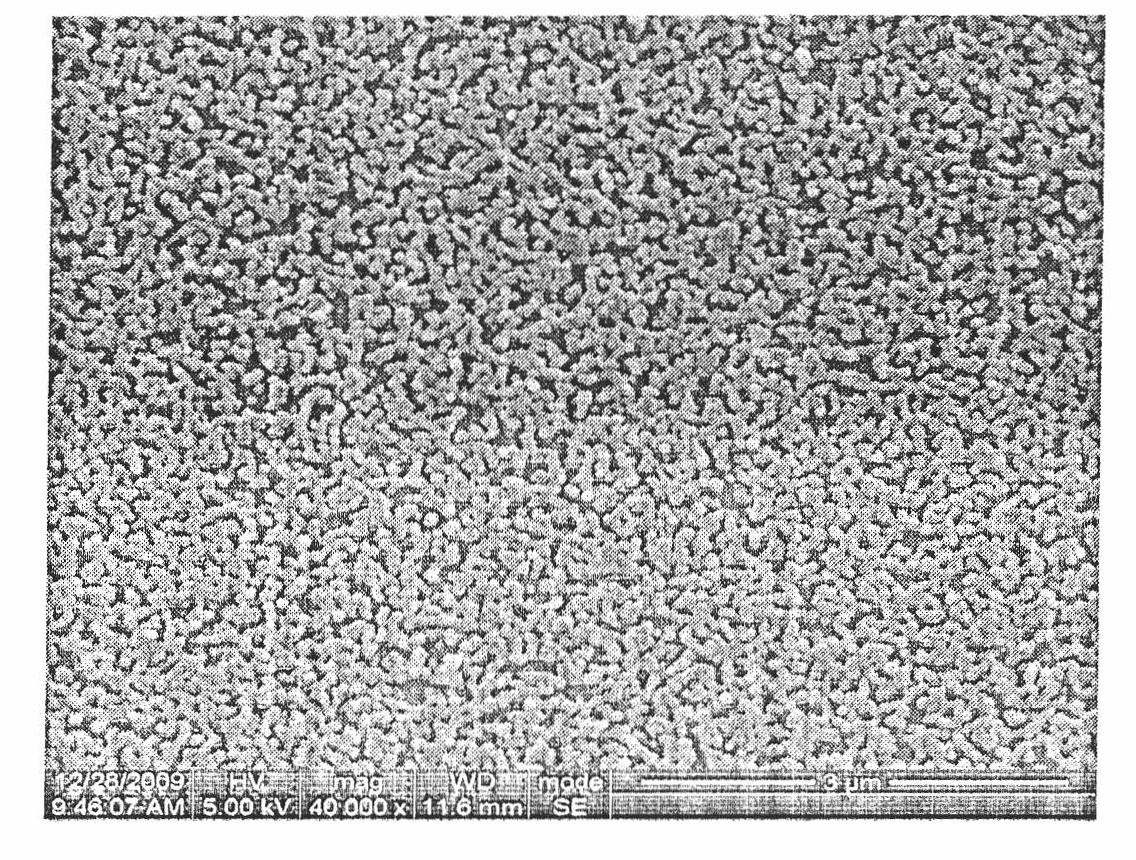

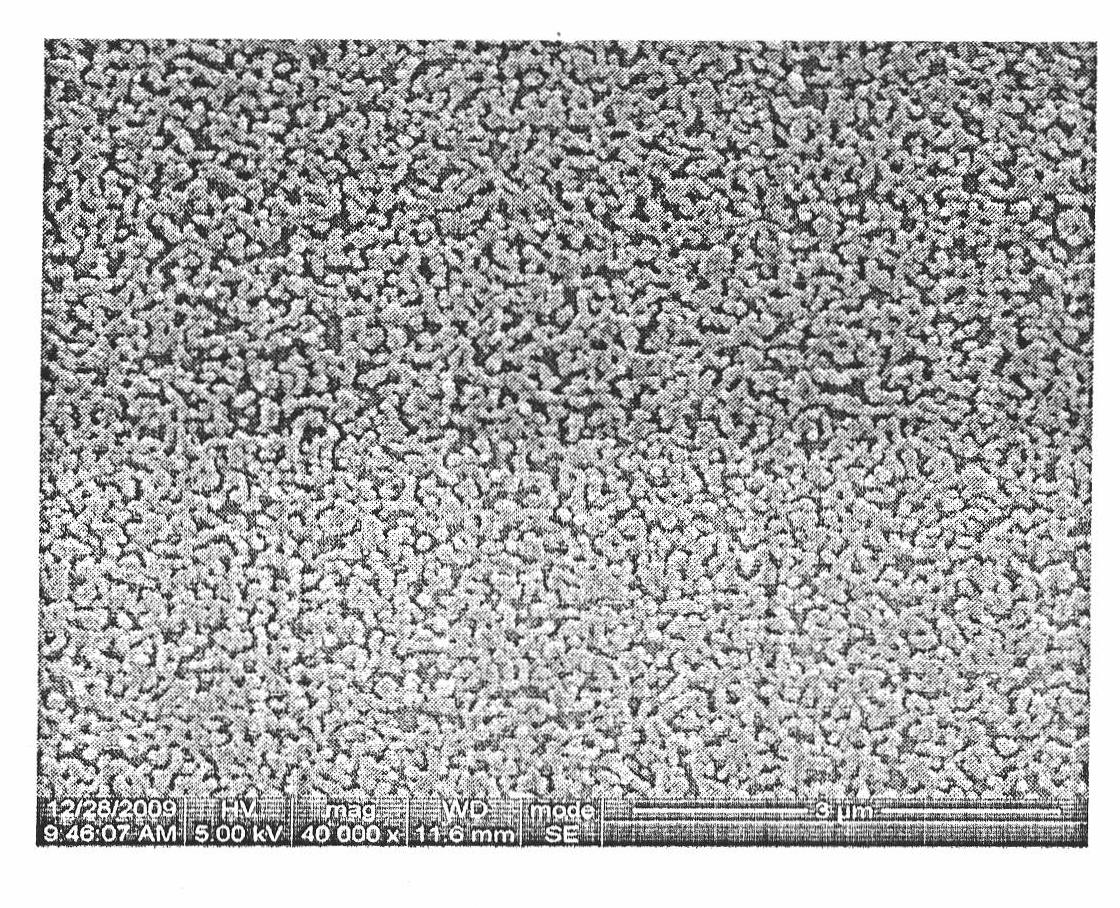

Image

Examples

Embodiment 1

[0034] Example 1 - Inorganic Substrate

[0035] The cleaning of the inorganic substrate is to first immerse the substrate in the washing solution prepared by concentrated sulfuric acid and hydrogen peroxide at a volume ratio of 3:1, then ultrasonically clean it with deionized water and ethanol in turn, and finally place it in a dry and clean container to dry for later use;

[0036] This embodiment is applicable to the cleaning of metal substrates, silicon wafer substrates, and inorganic oxide substrates such as glass and quartz.

Embodiment 2

[0037] Example 2 - Organic Substrate

[0038] The organic substrate was cleaned by ultrasonic cleaning three times with absolute ethanol, and then placed in a dry clean container to dry for later use.

[0039] This embodiment is applicable to the cleaning of polymethyl methacrylate (PMMA), polycarbonate (PC), polyester (PET), polystyrene (PSt) and other materials.

[0040] Examples of Nanoparticle Preparation

Embodiment 3

[0041] Embodiment 3-emulsion polymerization prepares organic nanoparticle-PMMA particle:

[0042] Add 300 g of deionized water and 0.6 g of emulsifier sodium lauryl sulfate in a 500 ml three-necked round bottom flask equipped with mechanical stirring, and start stirring to make the emulsifier completely dissolve in deionized water. Then add 60g of distilled and purified MMA monomer and pre-emulsify at about 23°C for about 30 minutes, then add 0.18g of potassium persulfate, pass nitrogen, slowly raise the temperature to about 70°C for about 5 hours, and then raise the temperature to about 80°C for about 30 minutes. 2 hours to complete the reaction. The resulting emulsion was filtered to obtain a PMMA emulsion with a particle size of about 60 nm and a distribution coefficient of 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com