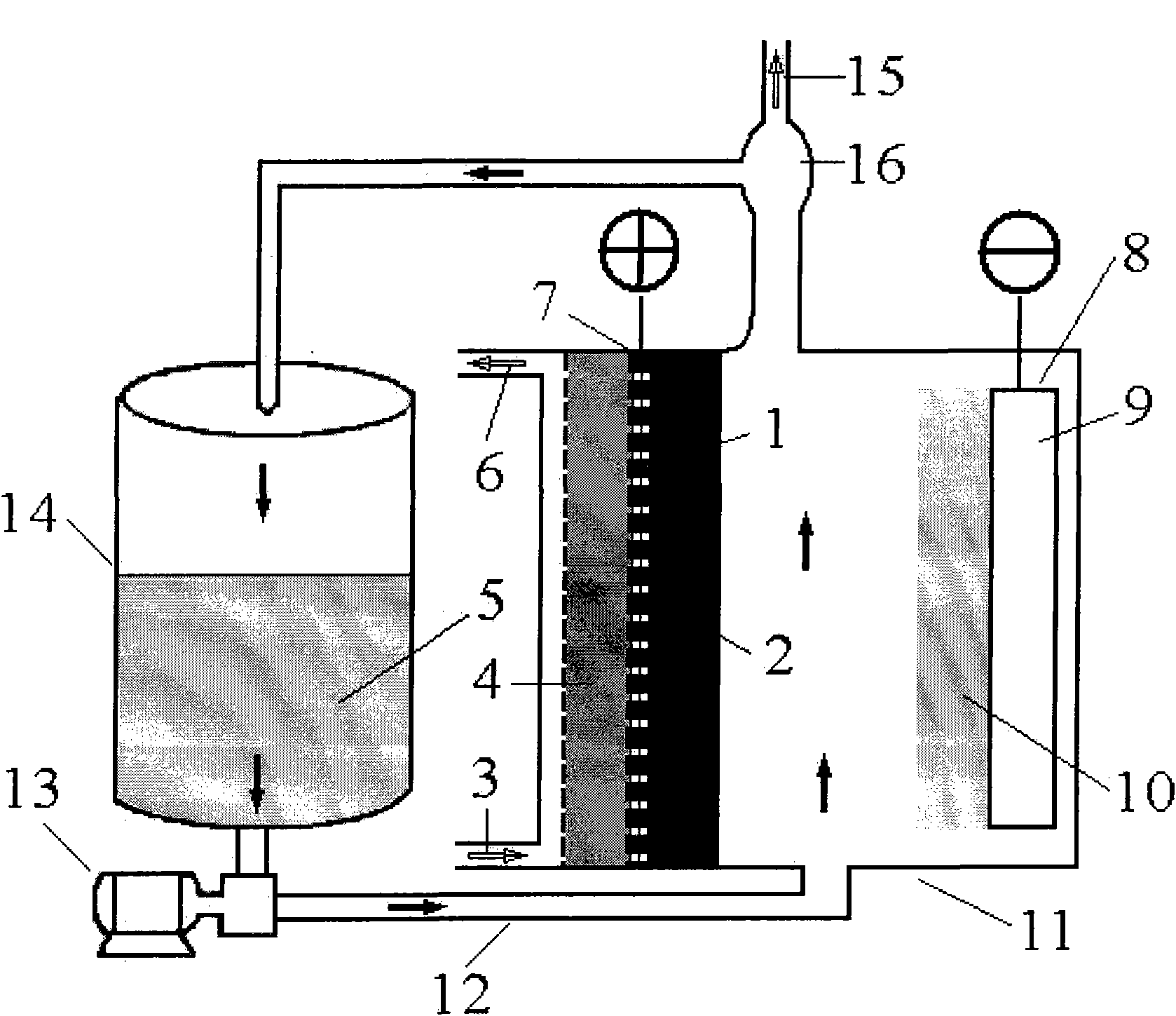

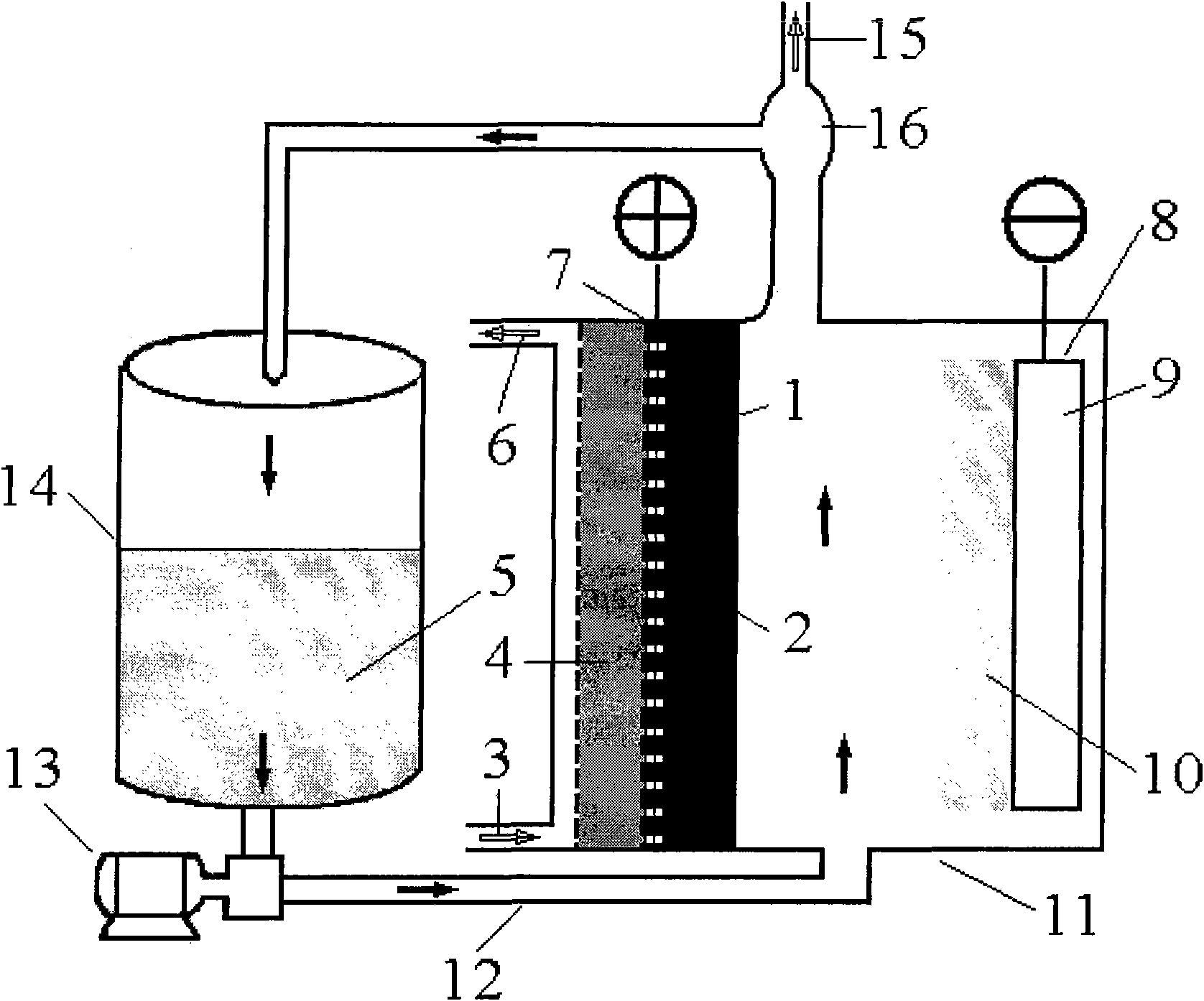

Zinc-oxygen single liquid flow cell

A flow battery, zinc-oxygen single technology, used in electric power, energy chemical industry, electronics industry, transportation, mining and metallurgy fields, can solve the problems of dendrite growth, unstable thermodynamic properties, easy deformation of electrodes, etc. The effect of energy density and power density, high energy utilization efficiency, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

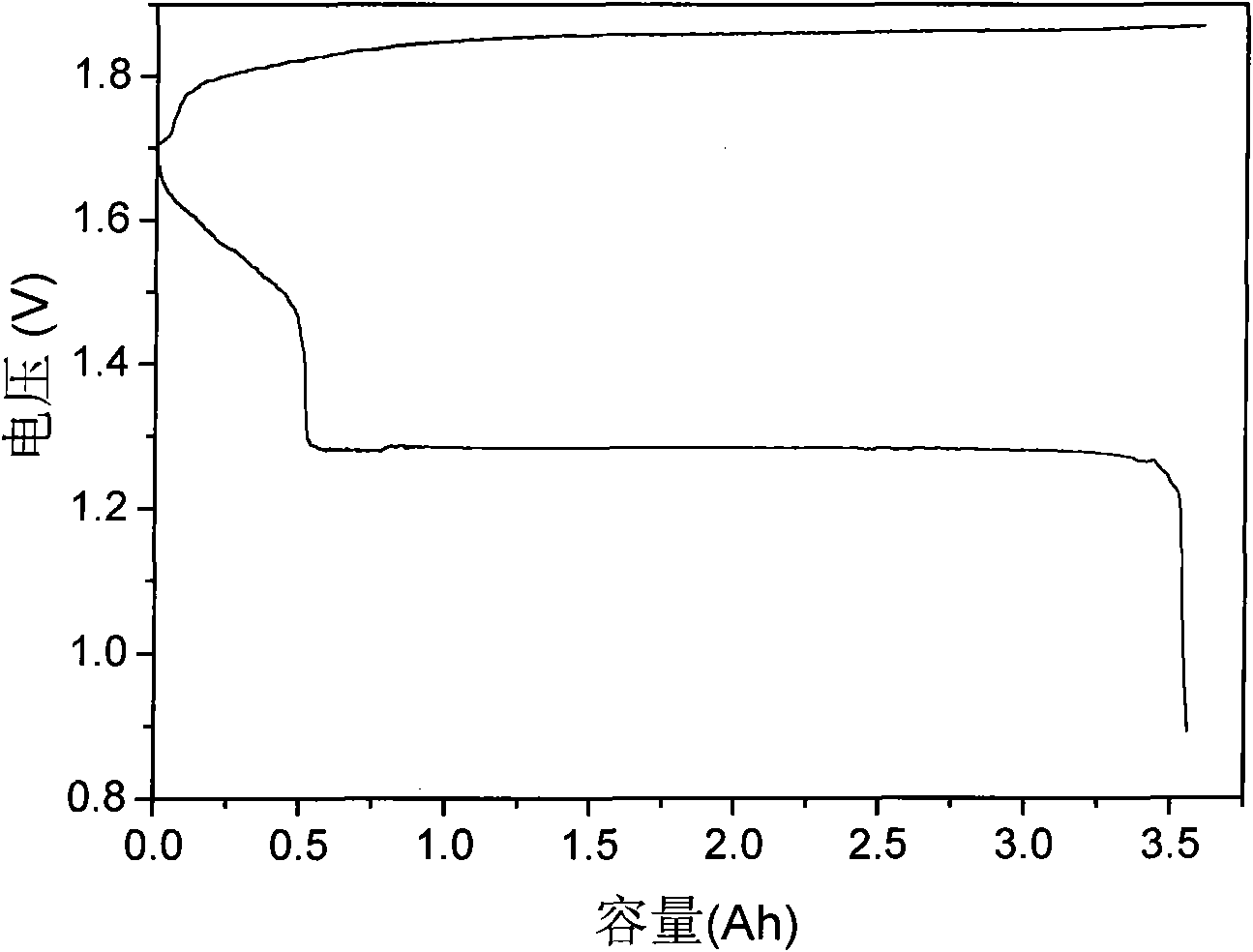

Examples

Embodiment 1

[0037] Positive electrode preparation

[0038] Nickel hydroxide and cobalt hydroxide are fully mixed according to a mass ratio of 95:5 and used as an oxygen evolution catalyst, nickel carbonyl powder is used as a conductive agent, and 60% (wt) polytetrafluoroethylene (PTFE) emulsion is used as a binder. The mass ratio is 85:10:5, mixed with propanol and water with a volume ratio of 1:1, and evenly scraped to a commercially available nickel foam with a thickness of 2.5mm (Hunan Kaiyuan Technology Co., Ltd. company) to form an oxygen evolution catalytic layer. Electrodeposition of NiCo with 3% (wt) Ag black powder 2 o 4 The powder is an oxygen reduction catalyst, nickel carbonyl powder is a conductive agent, and 60% (wt) PTFE emulsion is a binder, mixed in a ratio of 70:15:15 according to the mass ratio, and adjusted with acetone and water with a volume ratio of 1:1. Slurry was formed, and evenly scraped onto the other side of the nickel foam by wet squeegee method to form an...

Embodiment 2

[0046] Positive electrode preparation

[0047] The ternary composite hydroxide Ni with nickel, aluminum and cobalt 0.82 Al 0.15 co 0.03 (OH) 2 (atomic ratio) is an oxygen evolution catalyst, expanded graphite is a conductive agent, 60% (wt) polytetrafluoroethylene (PTFE) emulsion is a binder, mixes in the ratio of mass ratio 60: 25: 10, with 15ml volumetric concentration is 95% ethanol and 2ml of water were adjusted to make a slurry, then vacuum-dried at 80° C., and then repeatedly rolled into a 100 μm oxygen evolution catalytic membrane with a double-roll tablet press. To contain 5% (wt) NaBiO 3 The electrolytic manganese dioxide powder is an oxygen reduction catalyst, expanded graphite and acetylene black are a conductive agent, 60% (wt) PTFE emulsion is a binder, and the above four materials are mixed in a ratio of 60: 20: 5: 15 by mass, A slurry was prepared with acetone and water at a volume ratio of 1:1, dispersed by ultrasonic waves for 30 min, and the mixture was ...

Embodiment 3

[0055] Positive electrode preparation

[0056] Ag 2 O, Co(OH) 2 , Ni(OH) 2 The mixture is fully mixed according to the ratio of 10:5:85 in mass percentage and used as an oxygen evolution catalyst, the carbon powder is used as a conductive agent, and 60% (wt) polyvinylidene fluoride emulsion is used as a binder. Above-mentioned three kinds of materials are mixed with the ratio of mass ratio 80: 15: 5, with 25ml volume ratio is the mixed solvent of acetone and water of 1: 1 to adjust into slurry, evenly scrape with wet squeegee method to be 1.1mm in thickness, One side of the electrolytic nickel mesh with a pore diameter of 0.6 mm forms an oxygen evolution catalytic layer. electrolytic MnO 2 、Ag 2 O and NaBiO 3 The black powder after the powder is mixed evenly according to the mass ratio of 5:4:1 is the oxygen reduction catalyst, the graphite powder is the conductive agent, and the 60% (wt) PTFE emulsion is the binder, mixed in a ratio of 65:20:15 by mass, Use 20ml of ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com