Preparation method and application of transition metal phosphide Co2P

A transition metal and phosphide technology, applied in the field of transition metal phosphide synthesis, can solve the problems of unfavorable transition metal phosphide wide production and application, inability to form mass production, harsh production conditions, etc., and achieves good electrochemical reversibility and cost. Low, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take by weighing 0.562g cobalt sulfate heptahydrate, 0.332g ammonium hypophosphite (Co 2+ :H 2 PO 2 - = 1:2), add 25ml of deionized water to dissolve it completely, stir at 65°C for half an hour, and then put it into an oven for drying; put the dried precursor powder into a tube furnace (Tianjin City Zhonghuan Experimental Electric Furnace Co., Ltd. ZK-1BS), under the protection of argon atmosphere, calcined at 550°C for 6 hours; cooled to room temperature, washed the resulting product with deionized water three times, and then vacuum-dried it in an electric vacuum oven with a vacuum degree of -0.1MPa, the transition metal phosphide Co can be prepared 2 p.

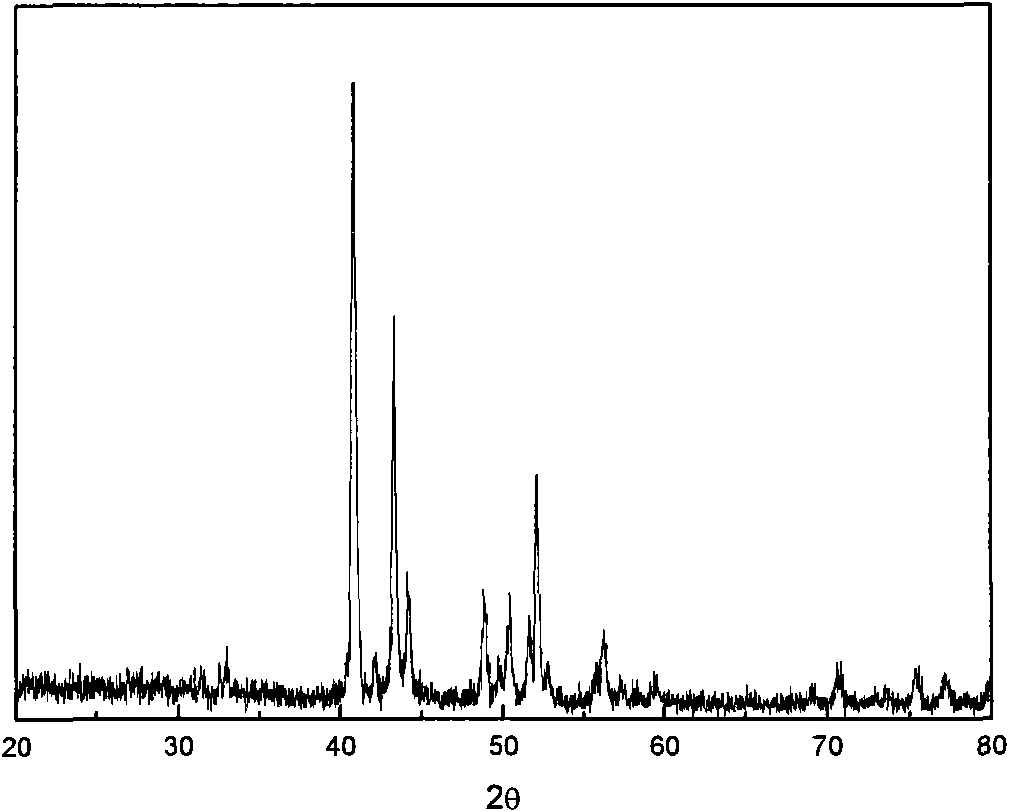

[0021] figure 1 For the XRD figure of gained material, adopt Rigaku D / Max Ш type X-ray diffractometer (Cu target k α Rays, wavelength λ=0.15418nm). Compared with the standard card, it can be seen that the synthesized material is orthorhombic (space group Pnam 62).

Embodiment 2

[0023] Take by weighing 0.595g cobalt chloride hexahydrate, 0.652g sodium hypophosphite (Co 2+ :H 2 PO 2 - =1:2.46), add 30ml of water, stir at 65°C for half an hour, then put it into an oven for drying; put the dried precursor powder into a tube furnace (ZK-1BS of Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd. ) under the protection of argon atmosphere at 600°C for 4 hours; cooled to room temperature, washed with deionized water for three times and then vacuum-dried in an electric vacuum oven with a vacuum degree of -0.1MPa to obtain Transition metal phosphides Co 2 p.

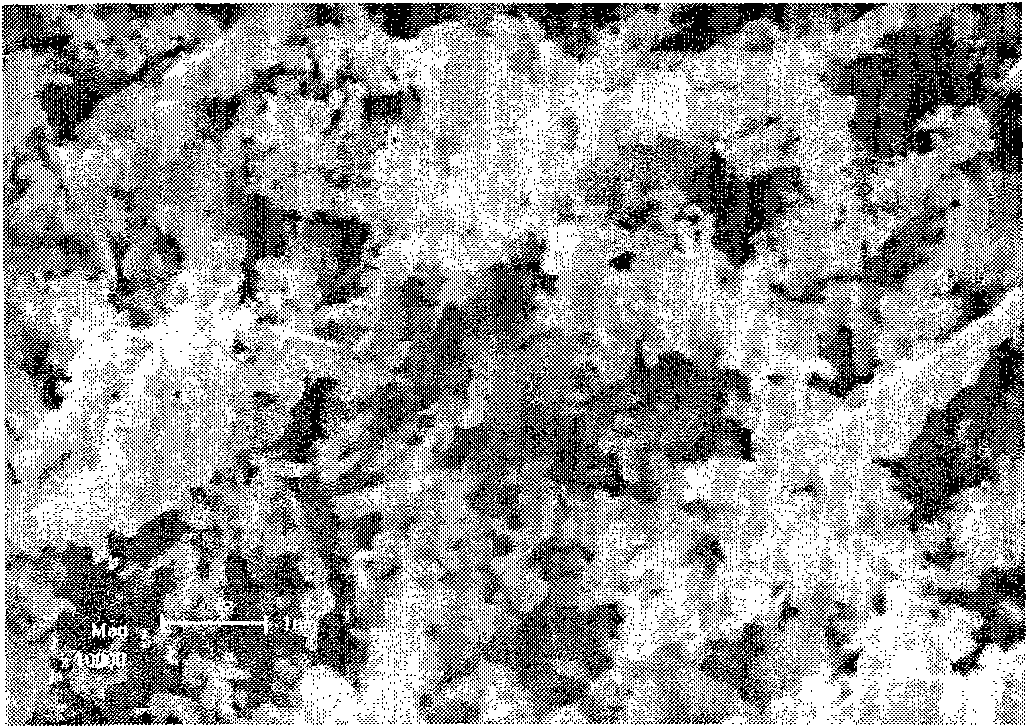

[0024] figure 2 For the prepared Co 2 SEM image of P.

Embodiment 3

[0026] Take by weighing 0.562g cobalt sulfate heptahydrate, 0.326g sodium hypophosphite (Co 2+ :H 2 PO 2 - =1:1.54), add 30ml of water, stir at 65°C for half an hour, then put it into an oven for drying; put the dried precursor powder into a tube furnace (ZK-1BS of Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd. ) under the protection of an inert gas at 650°C for 3 hours; cooled to room temperature, washed with deionized water for three times and then vacuum-dried in an electric vacuum oven with a vacuum degree of -0.1MPa to obtain Transition metal phosphides Co 2 p.

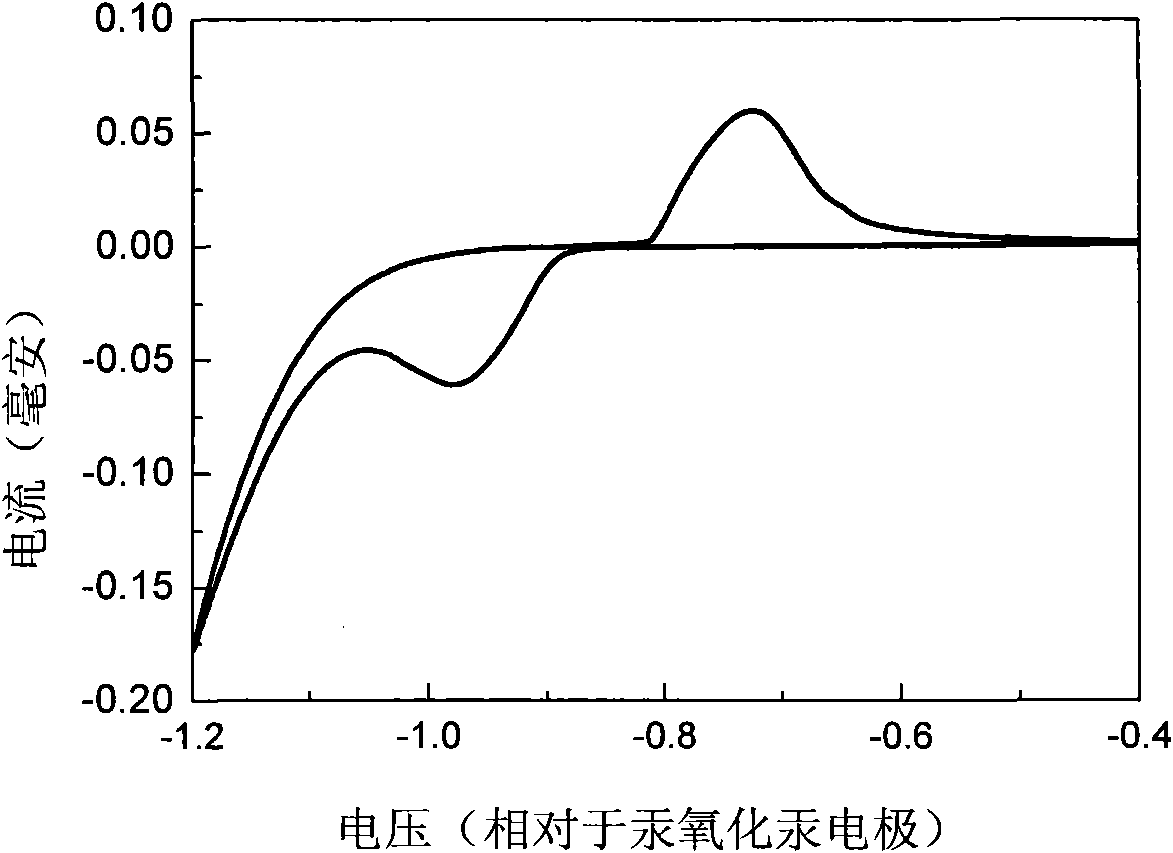

[0027] Accurately weigh Co 2 P, mixed with Ni carbonyl powder in a mass ratio of 1:3; then pressed into a disc with a diameter of 1 cm under a pressure of 30 MPa; clamp the disc with two pieces of nickel foam with a diameter of about 2 cm, and compact it with a pressure of 20 MPa; Finally, spot weld metal nickel sheet on the edge of nickel foam to make nickel metal hydride battery negative electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com