Engineering bacteria with high tolerance to acrylamide and acrylonitrile for producing nitrile hydratase and application thereof

A technology of acrylamide and nitrile hydratase, which is applied in the direction of bacteria, biochemical equipment and methods, and the use of vectors to introduce foreign genetic materials. Increased, high-concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

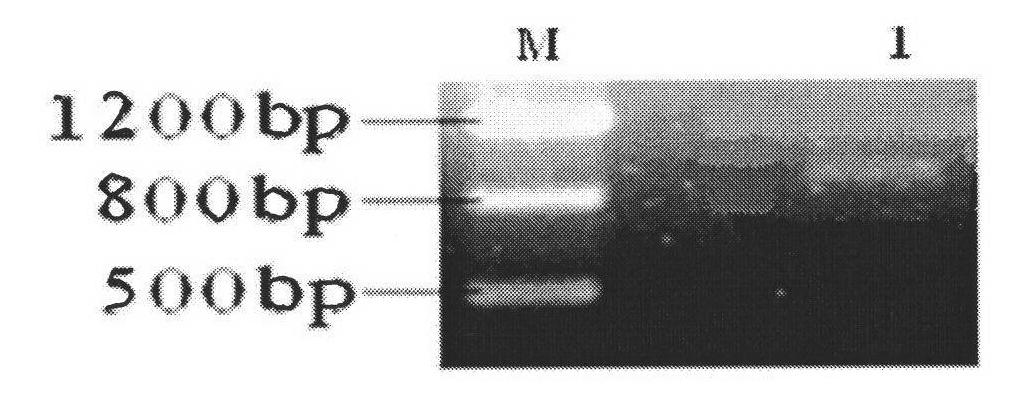

[0051] Example 1 Cloning of the sigA gene and upstream sequence encoding sigma 70 in Rhodococcus ruber TH3 (amdA-)

[0052] (1) Cultivation of Rhodococcus ruber TH3(amdA-) and extraction of total genomic DNA

[0053] Pick Rhodococcus ruber TH3 (amdA-) with a sterile inoculation loop (preserved in this laboratory, and preserved in the General Microbiology Center of China Microbiological Culture Collection Management Committee on February 27, 2008, and the strain preservation registration number is CGMCC No.2381) single colony, inoculated in 50mL LB liquid fermentation medium (the composition and ratio of LB liquid fermentation medium are: glucose 10g / L; yeast extract 5g / L; peptone 10g / L; sodium chloride 10g / L L, the rest is water) in a conical flask; then cultivated in a shaker at a temperature of 28°C and a rotation speed of 200rpm for 72 hours, and then centrifuged at 10000rpm for 5min to collect bacterial precipitates, resuspended in 10ml sterile water, and placed at 10000rp...

Embodiment 2

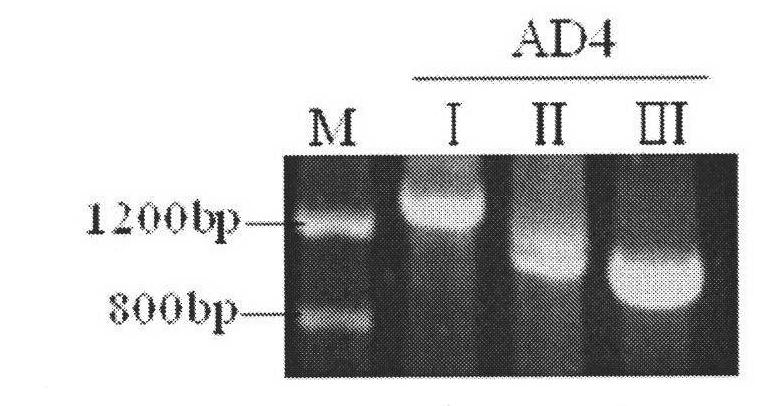

[0080] Example 2 Construction of sigA gene random mutation library

[0081] (1) Construction of recombinant plasmids for random mutation

[0082] According to the sequence information of the sigA gene fragment obtained in Example 1, primers EsigAup and HsigAdown whose amplified product contains the full-length and upstream sequence of the sigA gene were designed. The above primer sequences are as follows:

[0083] EsigAup: 5′-TCA GAATTC TCGTTACAATGGTGCACAG-3' (the underline is the EcoRI restriction site); (SEQ ID No: 12)

[0084] HsigAdown: 5′-ACA AAGCTT CGCGTTCAGTCCAGGTAGT-3' (the underline is the HindIII restriction site). (SEQ ID No: 13)

[0085] Using Rhodococcus R. ruber TH3 (amdA-) genomic DNA as a template, and using EsigAup and HsigAdown as upstream and downstream primers respectively, PCR amplification was carried out. The reaction system and amplification conditions were the same as step (2) of Example 1. The amplified product (the product contains the sigA g...

Embodiment 3

[0088] Example 3 Screening of Propionamide Growth Tolerance Enhanced Mutants

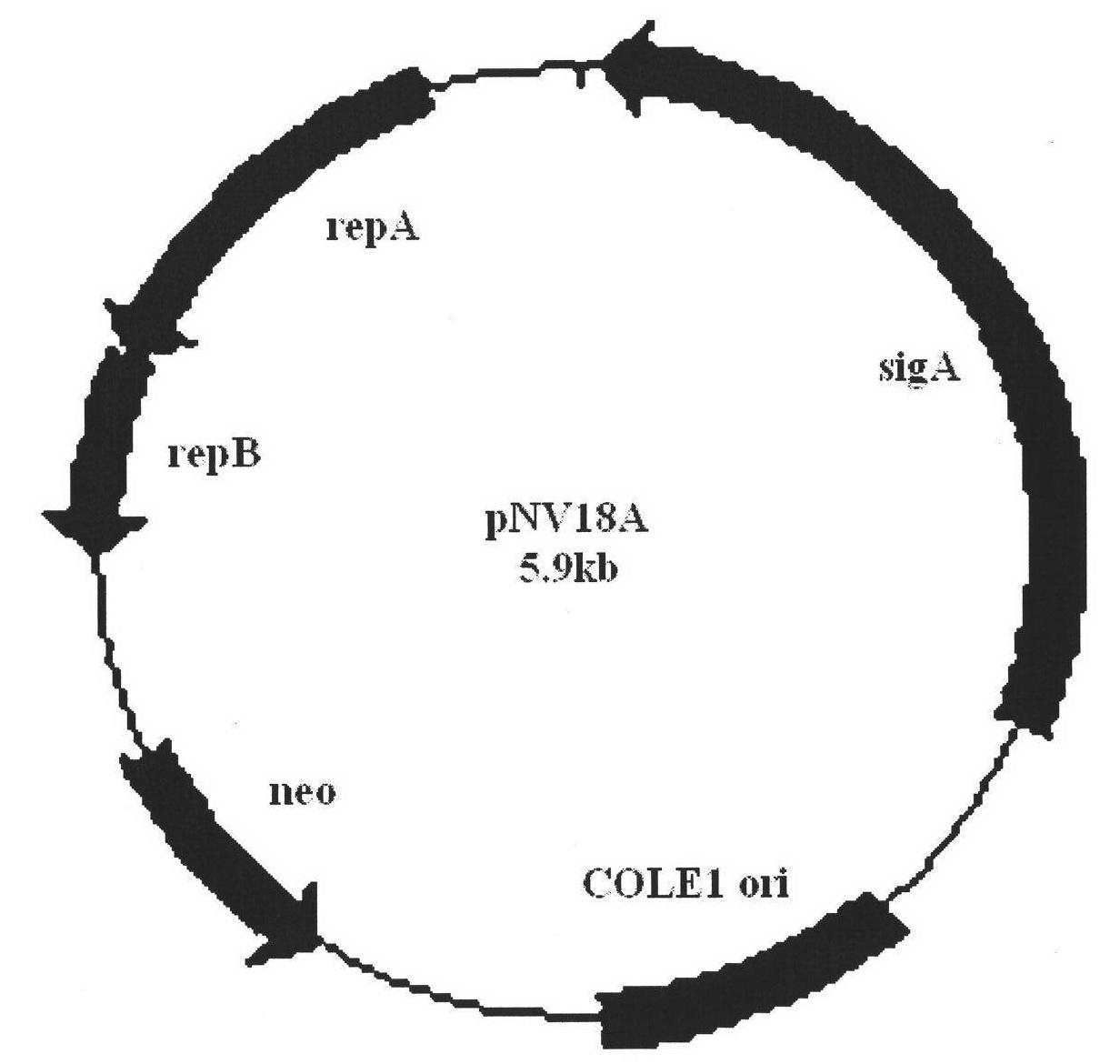

[0089]The sigA gene random mutation plasmid library constructed in Example 2 was transformed by electroporation into the competent cells of the engineered Rhodococcus R.ruber TH3 (amdA-) whose amidase gene was knocked out, with kanamycin resistance and lethal acrylamide The acrylamide tolerance enhanced mutants were screened under the condition of concentration (4mg / ml). At the same time, the recombinant plasmid pNV18A containing the endogenous natural sigA gene prepared in step (2) of Example 2 was also transferred into R. ruberTH3 (amdA-) to construct strain TH3A as a control reference strain. Wherein, the preparation of Rhodococcus competent cells adopts the preparation method of Gram-positive bacteria competent cells in "Molecular Cloning Guidelines" (J. Sambrook, D.W. Russell). Take 1 μl of the purified plasmid in a 1.5ml centrifuge tube, and place it together with a 0.1CM electroporation cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com