Molecular-recognition separation membrane and preparation method and application thereof

A molecular recognition and separation membrane technology, applied in the field of separation membranes, can solve the problems of difficult recovery and reuse of adsorbents, obstacles to practical application, lack of regeneration methods, etc., achieve significant adsorption capacity, improve reusability, and simple immobilization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

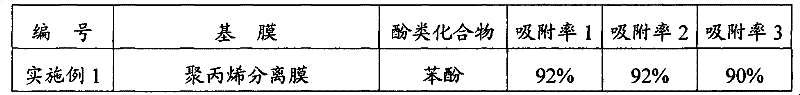

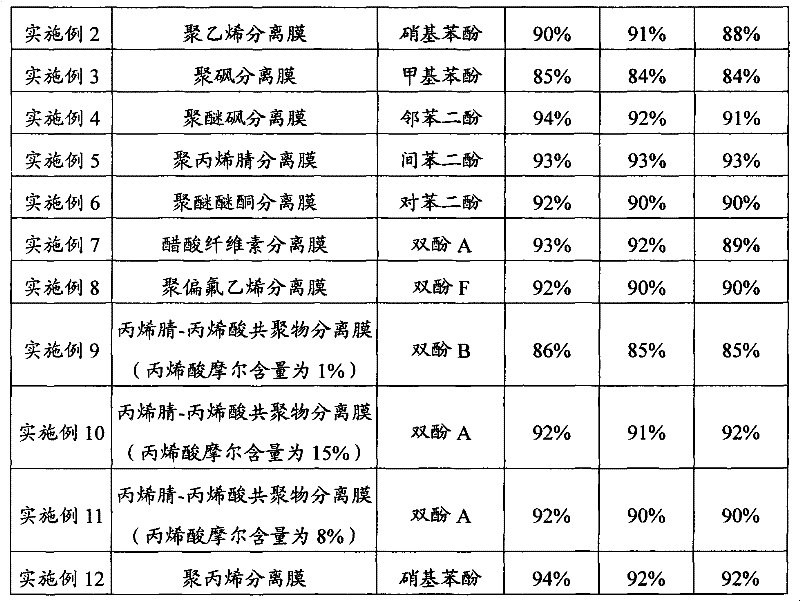

Examples

Embodiment 1

[0039] The carboxyl-containing polypropylene separation membrane on the surface prepared by the following method is used as the base membrane: the polypropylene separation membrane is immersed in the n-heptane solution of the photoinitiator benzophenone with a concentration of 1 mmol / L, and after 1 hour, it is naturally After drying, the membrane is immersed in an acrylic acid aqueous solution with a monomer volume concentration of 10%, taken out after being irradiated with ultraviolet light for 20 minutes, washed and dried to obtain a polypropylene separation membrane with carboxyl groups on the surface.

[0040] The base film was immersed in an aqueous solution of 1-ethyl-3-(N,N-dimethylaminopropyl)carbodiimide and N-hydroxysuccinimide at a molar ratio of 1:1 (1-ethyl -3-(N, N-dimethylaminopropyl) carbodiimide concentration is 1mg / mL), soaked for 0.5 hours to activate, wash, and then immerse the activated basement membrane in a concentration of 50mmol / L, The solvent is 50% eth...

Embodiment 2

[0045] Use the carboxyl-containing polyethylene separation membrane on the surface prepared by the following method as the base membrane: prepare a 5g / L polyacrylic acid aqueous solution, then immerse the polyethylene separation membrane in the solution, shake it at room temperature for 3 hours, take it out and dry it in the air , and then treated in an atmospheric pressure plasma apparatus for 30 seconds, washed and dried to obtain a polyethylene separation membrane containing carboxyl groups on the surface.

[0046] The base film was immersed in an aqueous solution of 1-ethyl-3-(N,N-dimethylaminopropyl)carbodiimide and N-hydroxysuccinimide at a molar ratio of 1:1 (1-ethyl -3-(N, N-dimethylaminopropyl) carbodiimide concentration is 10mg / mL), soak for 1 hour to activate, wash, and then immerse the activated basement membrane in a concentration of 20mmol / L, The solvent is the aminophenylboronic acid solution with 20% ethanol solution by volume to react for 1 hour, and the amino...

Embodiment 3

[0051] The carboxyl-containing polysulfone separation membrane on the surface prepared by the following method is used as the base membrane: the polysulfone separation membrane is immersed in the n-heptane solution of the photoinitiator benzophenone with a concentration of 1 mmol / L, and after 1 hour, it is naturally After drying, the membrane is immersed in an acrylic acid aqueous solution with a monomer volume concentration of 10%, taken out after being irradiated with ultraviolet light for 20 minutes, washed and dried to obtain a polysulfone separation membrane with carboxyl groups on the surface.

[0052] Immerse the base film in an aqueous solution of 1-ethyl-3-(N,N-dimethylaminopropyl)carbodiimide and N-hydroxysuccinimide (1-ethyl- 3-(N,N-Dimethylaminopropyl) carbodiimide at a concentration of 0.1mg / mL), soak for 3 hours to activate, wash, and then immerse the activated basement membrane in a concentration of 1mmol / L 1. The solvent is 80% ethanol aqueous solution and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com