Superlattice multilayer film and preparation method thereof

A multi-layer film and superlattice technology, used in coatings, layered products, nanostructure manufacturing, etc., can solve problems such as low hardness and limitations, and achieve the effect of improving bonding strength, improving stress distribution, and expanding application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

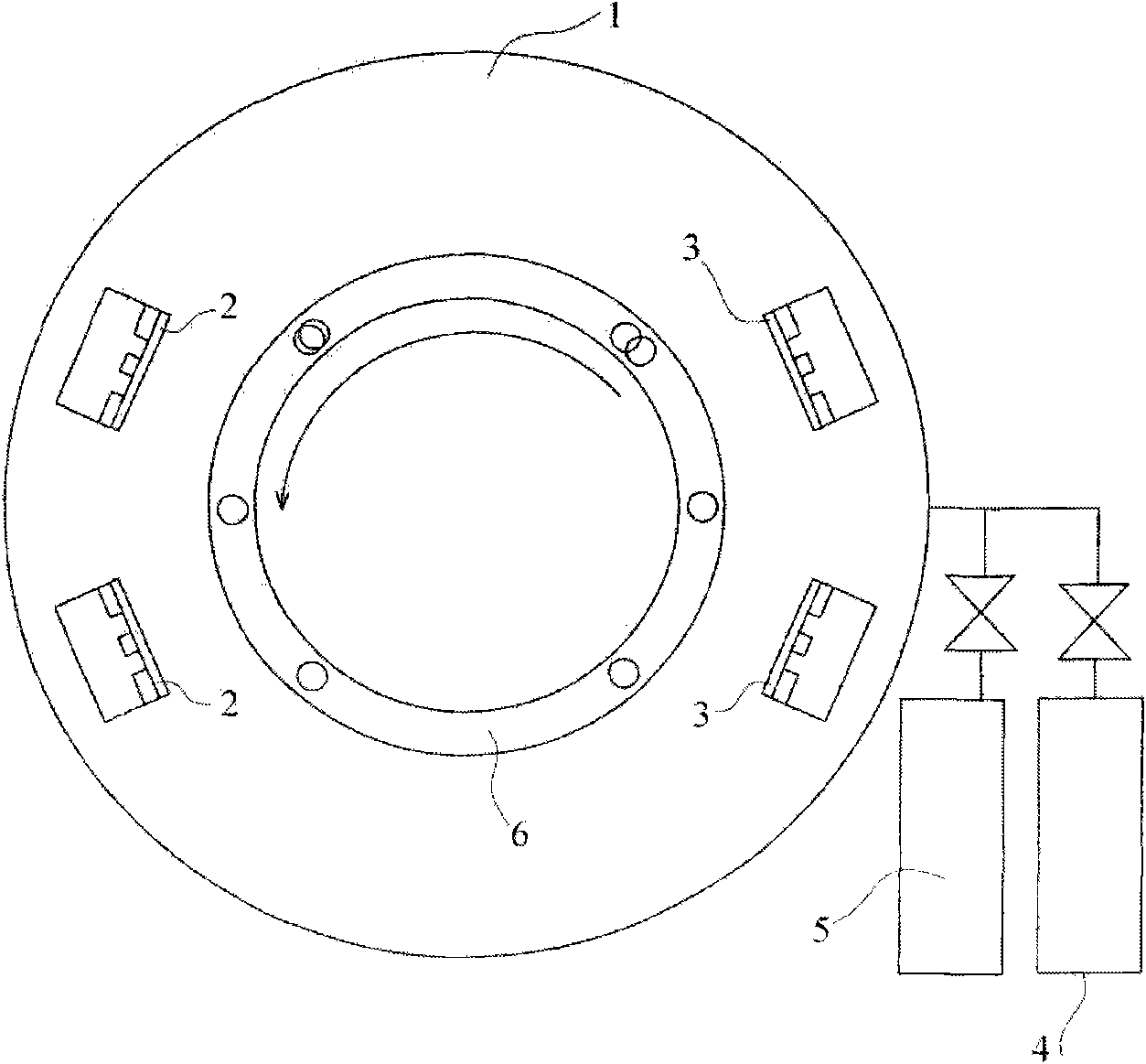

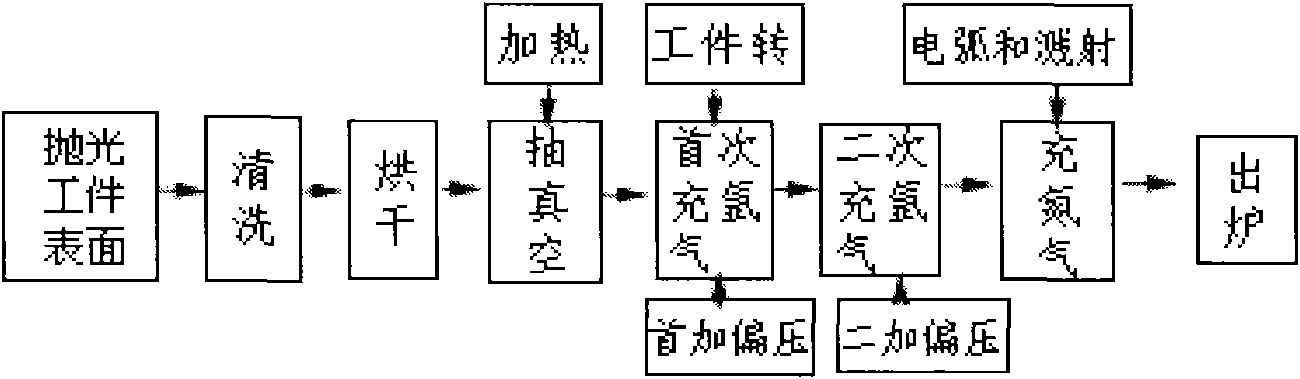

[0036] Such as figure 1 , figure 2 As shown, the present embodiment comprises the following steps: (1) one side in the vacuum chamber 1 is provided with a pair of intermediate frequency DC magnetron sputtering sources 2, and the other side is relatively provided with a pair of arc sources 3; N 2 Gas 4 and Ar gas 5 are connected to the vacuum chamber 1, and Si(001) is selected as the workpiece, and the size of the workpiece is 1×30×40mm 3 ;

[0037] (2) After polishing treatment, use acetone and alcohol to ultrasonically clean each for 10 minutes, and then install it on the turntable 6 in the vacuum chamber 1 after drying. The vacuum degree of the vacuum chamber 1 is 3.5×10 -3 Pa, the workpiece heating temperature is 320°C, and the workpiece rotates 10 revolutions / min;

[0038] (3) Pass Ar gas 5 into the vacuum chamber 1, the flow rate of the Ar gas 5 is 20SCCM, and the bias voltage is 600V, and the surface of the workpiece is bombarded and cleaned with Ar ions for 10 minut...

Embodiment 2

[0050] In this embodiment: Step (3) feeds Ar gas 5 into vacuum chamber 1, the flow rate of feeding Ar gas 5 is 20 SCCM, and the bias voltage is 600V, and Ar ion bombardment cleaning is carried out on the surface of the workpiece for 10 minutes to remove residual residues on the surface of the workpiece. After removing the adsorbates and oxides, reduce the bias voltage to 400V. Other implementation conditions are identical with embodiment 1.

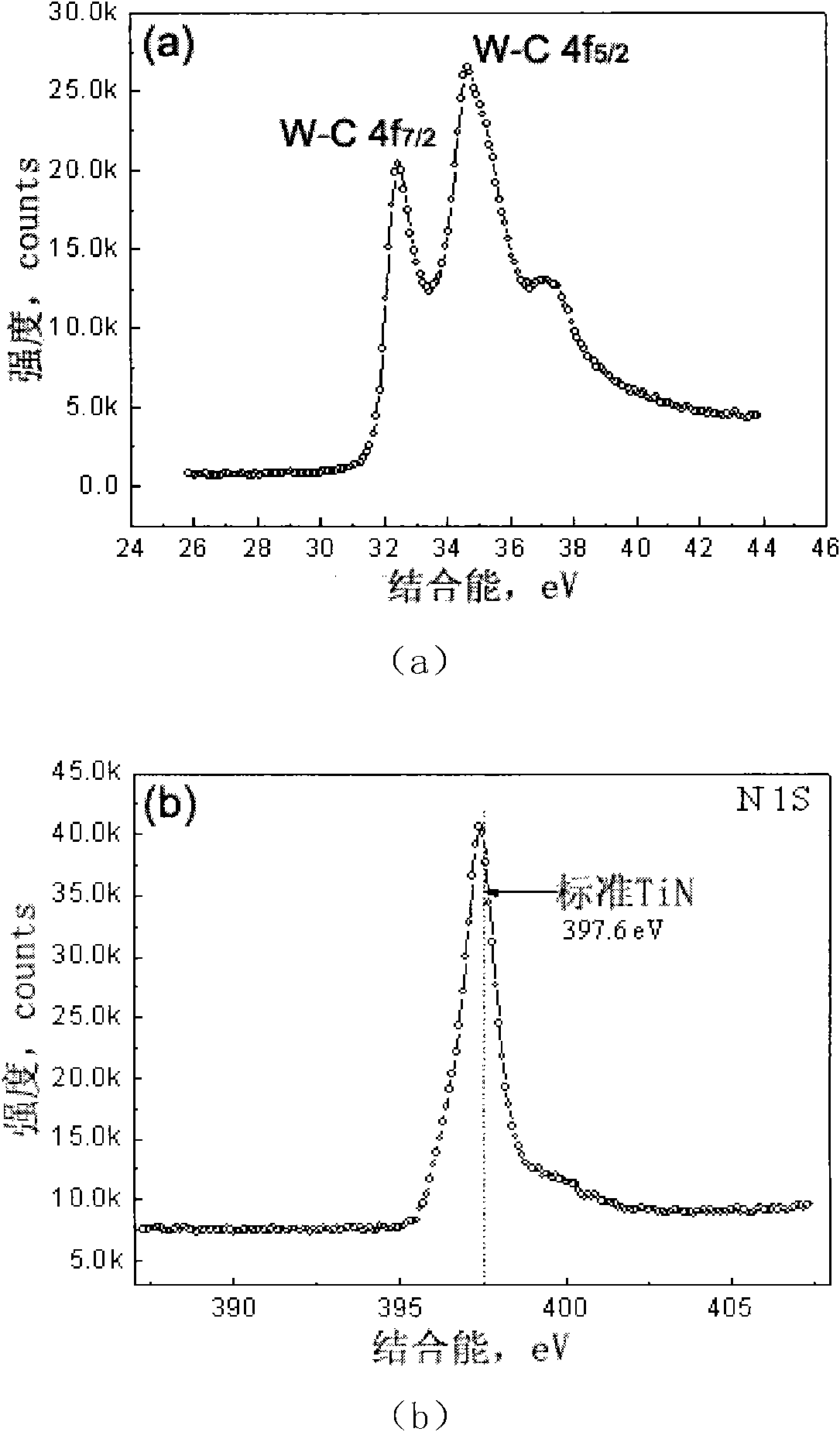

[0051] Such as Figure 5 As shown, by HRTEM detection and analysis, the modulation period of the superlattice obtained in this embodiment is 5nm, and the thicknesses of TiN and WC monolayers are about 4nm and 1nm respectively.

[0052] The total thickness of the superlattice multilayer film in this embodiment is 2.5 µm.

[0053] Such as Figure 7 As shown, the hardness of the superlattice multilayer film is detected by the nanoindentation method, the maximum load is 40mN, and the hardness value of the film layer is 52±2GPa.

[0054] S...

Embodiment 3

[0057] In the present embodiment: step (5) adds N to the vacuum chamber 1 2 Gas 4, add N 2 The flow rate of the gas 4 is 20 SCCM, and it works for 60 minutes to deposit and form the TiN nanocrystalline phase layer 7 and the WC amorphous phase layer. When the vacuum chamber 1 is cooled to room temperature, open the furnace door and take out the workpiece. Other implementation conditions are identical with embodiment 1.

[0058] Such as Figure 6 As shown, by HRTEM detection and analysis, the modulation period of the superlattice obtained in this embodiment is 3nm.

[0059] The total thickness of the superlattice multilayer film in this embodiment is 2.5 µm.

[0060] Such as Figure 7 As shown, the hardness of the superlattice multilayer film is detected by the nanoindentation method, the maximum load is 40mN, and the hardness value of the film layer is 44±2GPa.

[0061] Such as Figure 8 As shown, the hardness value and elastic modulus of the superlattice multilayer film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Fracture toughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com