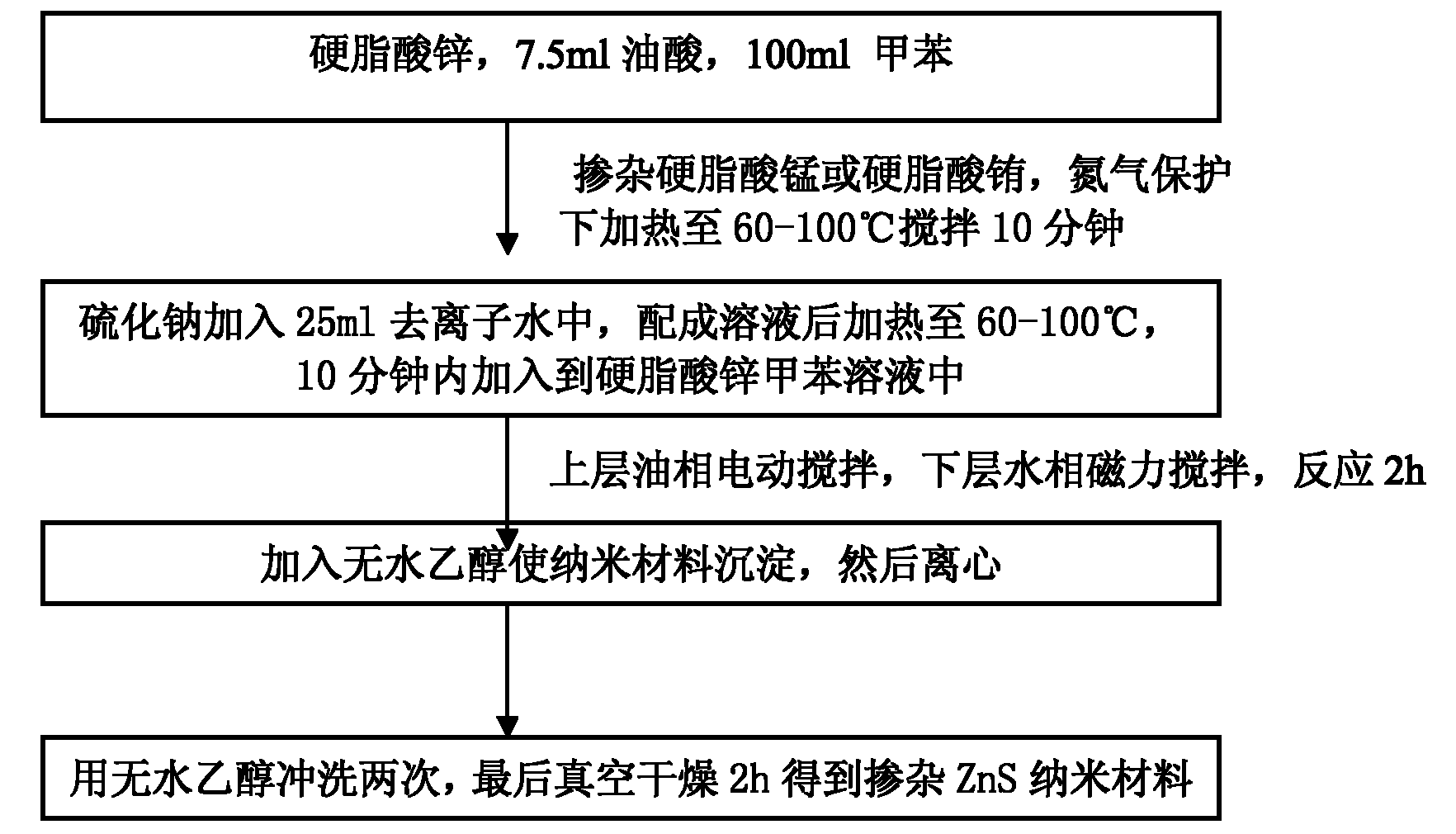

Method for synthesizing ZnS-doped nanometer luminescent material by oil-water interface method

A nano-luminescent material, oil-water interface method technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of difficult particle size control, easy agglomeration, low particle purity, etc., and achieve good application prospects, mild reaction conditions, and fluorescence intensity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Take 1.2620g (0.002mol) of zinc stearate, dissolve it in 100ml of toluene at 100°C, add 7.5ml of oleic acid, stir evenly under nitrogen protection, and save it for later use;

[0038] (2) Take 0.5764g (0.0024mol) Na 2 S·9H 2 O was dissolved in 25ml of deionized water at 100°C, stirred evenly, and stored for later use;

[0039] (3) Add the sodium sulfide aqueous solution prepared in step 2 to the zinc stearate toluene solution prepared in step 1 within 10 minutes, under the temperature of 100°C and under the protection of nitrogen, the upper layer is electrically stirred, the lower layer is magnetically stirred for 2 hours, and anhydrous ethanol is added for precipitation , and then centrifuged, washed twice with absolute ethanol, and finally vacuum-dried to obtain ZnS nanomaterials.

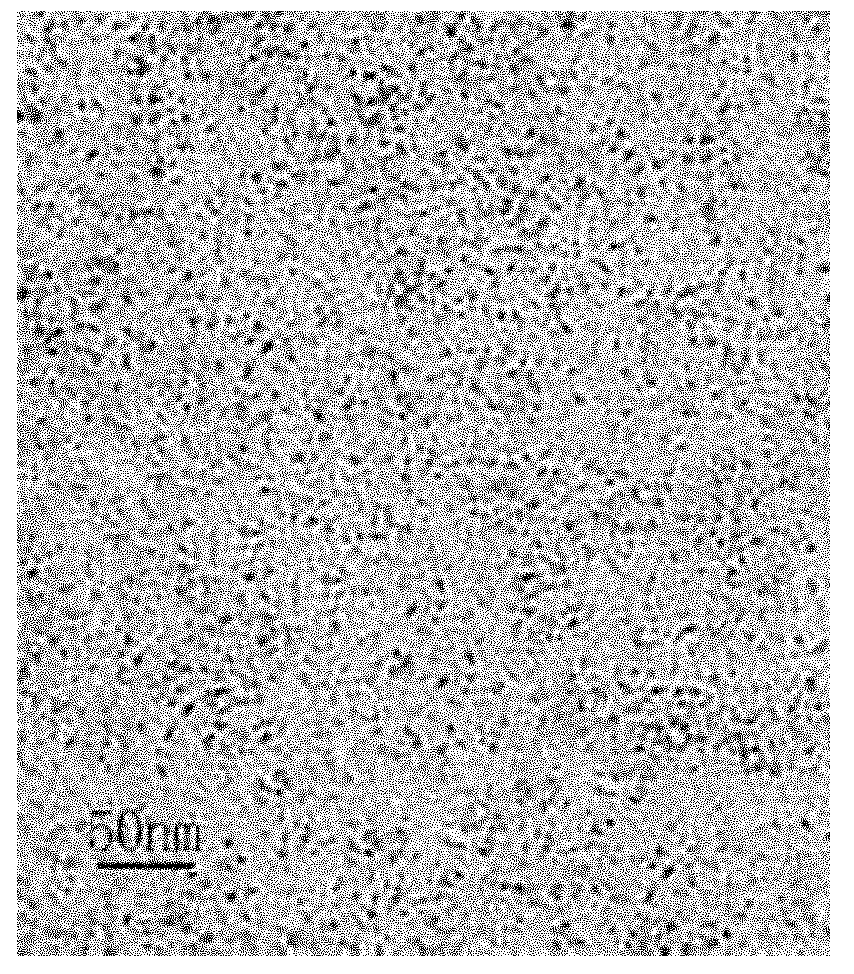

[0040] image 3 It is a TEM image of ZnS nanomaterials prepared by reacting at 100°C for 2 hours. It can be estimated from the image that the average particle size of the particles ...

Embodiment 2

[0042] Change the zinc stearate quality in process 1 in embodiment 1 to 0.6310g and 2.5240g, and all the other reaction processes and conditions are unchanged.

[0043] Figure 5 It is the ultraviolet absorption diagram of the ZnS nanomaterials prepared when the zinc ion molar concentration is 0.01M, 0.02M and 0.04M respectively. It can be seen from the figure that when the zinc ion molar concentration is 0.02M, the ultraviolet absorption intensity of the obtained ZnS nanomaterial is the largest.

Embodiment 3

[0045] Change the stirring time in process 3 in Example 1 to 0.5h, 1.0h and 4h, and the rest of the reaction process and conditions remain unchanged.

[0046] Figure 6The ultraviolet absorption diagrams of the ZnS nanomaterials prepared when the reaction time is 0.5h, 1.0h, 2h and 4.0h respectively. It can be seen from the figure that when the reaction time is 2h, the ultraviolet absorption intensity of the obtained ZnS nanomaterials is the largest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com