Polymer composite material embedded microcapacitor and preparation method thereof

A composite material and polymer technology, applied in the direction of multilayer capacitors, fixed capacitor parts, fixed capacitor dielectrics, etc., can solve the problems of low electrical performance and poor reliability, and achieve high dielectric constant, low loss, and improved The effect of electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The method for preparing polymer composite embedded microcapacitors provided by the present invention includes the following steps:

[0024] 1) Use in-situ polymerization to disperse BT nanoparticles into PI to prepare dielectric thin film PI / BT composites. The specific process is as follows:

[0025] (11) Mix BT nanoparticles with a diameter of 50-300 nm and a coupling agent with a volume percentage of 1 to 3 vol% in an alcohol solution. After mixing, stir ultrasonically for 1-2 hours, and then bake at 80-100°C. dry;

[0026] (12) First add the solvent N,N-dimethylacetamide (DMAc) into the container, then add 10-50vol% BT nanoparticles in the container, and add the corresponding content of 4,4'-diamino Terephthalic ether (ODA), ultrasonic for 40-60 minutes to milky suspension, stir for 10-30 minutes;

[0027] (13) Then, while stirring, add pyromellitic dianhydride (PMDA) with a molar ratio of 1:1 to ODA into the container of step (12) three times at an interval of 8-10 minute...

Embodiment 1

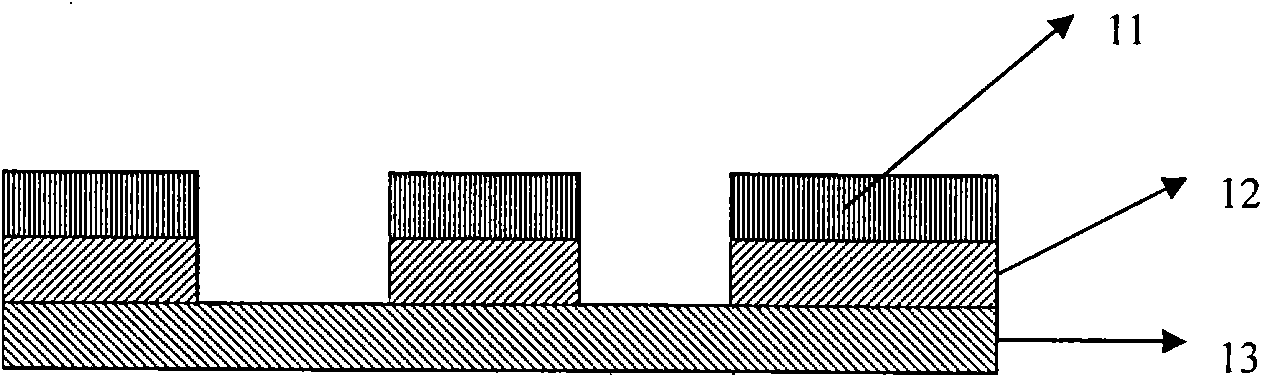

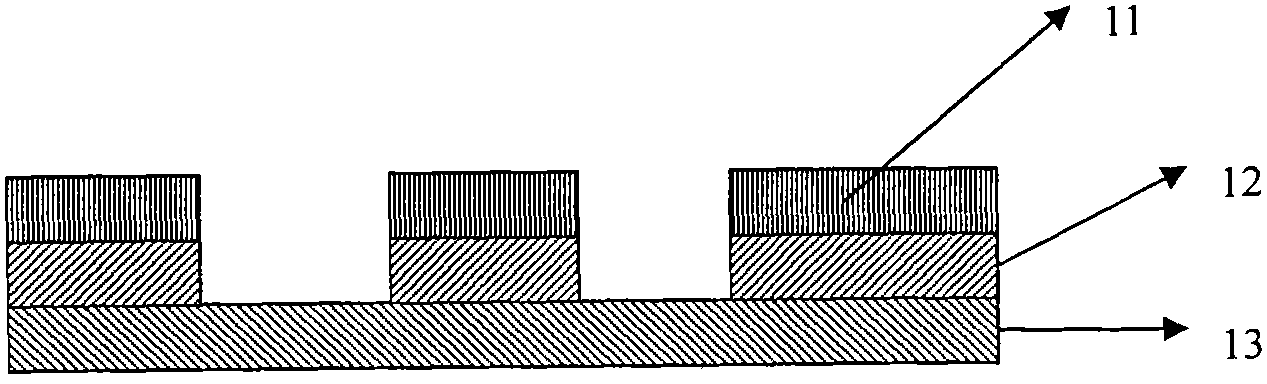

[0039] The embedded microcapacitor provided by the present invention is such as figure 1 As shown, the upper electrode 11, the dielectric film 12 and the lower electrode 13 are included. Wherein, the dielectric film 12 uses the PI / BT composite material with a thickness of 10um.

[0040] The PI / BT composite material of the present invention includes polymer PI and BT nanoparticles dispersed in the polymer; the volume content of the BT nanoparticles is 10 vol% of the total volume of the PI / BT composite material.

[0041] The material of the upper electrode and the lower electrode is TiW / Cu, and the thickness of the metal electrode is 200 nm.

[0042] The manufacturing method of the embedded microcapacitor provided by the present invention includes the following steps:

[0043] 1) Use in-situ polymerization to disperse BT nanoparticles into PI to prepare dielectric thin film PI / BT composites. The specific process is as follows:

[0044] (11) Mix BT nanoparticles with a diameter of 50 nm a...

Embodiment 2

[0055] The embedded microcapacitor provided by the present invention is such as figure 1 As shown, the upper electrode 11, the dielectric film 12 and the lower electrode 13 are included. Wherein, the dielectric film 12 uses the PI / BT composite material with a thickness of 50um.

[0056] The PI / BT composite material of the present invention includes polymer PI and BT nanoparticles dispersed in the polymer; the volume content of the BT nanoparticles is 40 vol% of the total volume of the PI / BT composite material.

[0057] The material of the upper electrode and the lower electrode is TiW / Cu, and the thickness of the metal electrode is 562 nm.

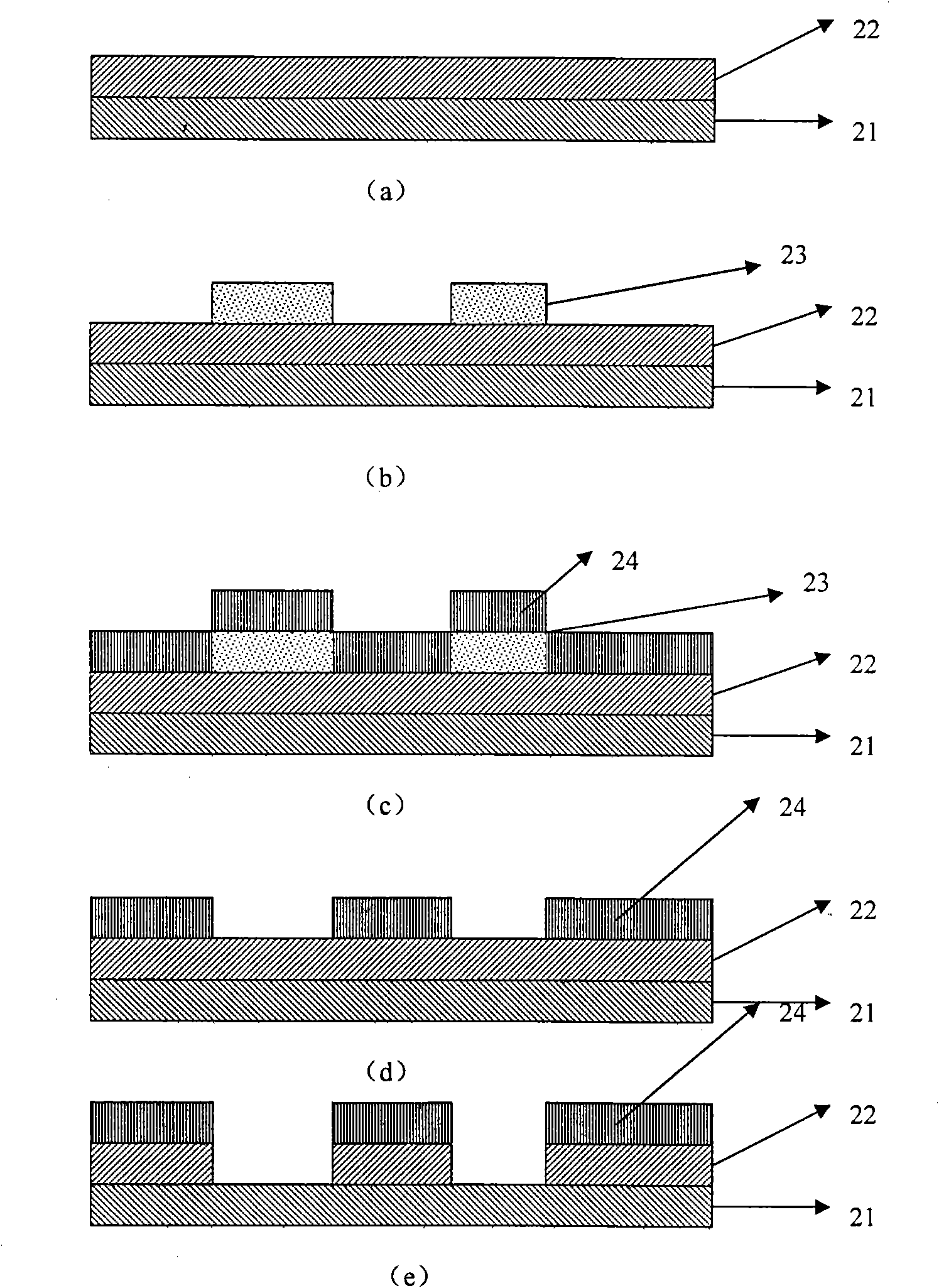

[0058] The manufacturing method of the embedded microcapacitor provided by the present invention includes the following steps, such as figure 2 Shown.

[0059] 1) Use in-situ polymerization to disperse BT nanoparticles into PI to prepare dielectric thin film PI / BT composites. The specific process is as follows:

[0060] (11) Mix BT nanoparticles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com