Thermoplastic elastomer styrene-isoprene-styrene (SIS) framework material extruded and coated by extruder

A framework material and content technology, applied in the field of thermal elastomer SIS framework material, can solve the problems of insufficient cohesion, backing glue penetration, low drug loading, etc., and achieve the effect of improving curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of novel SIS: SIS was synthesized by a three-step method.

[0034] 1: Recipe calculation

[0035] Design: styrene / isoprene = 15 / 85; molecular weight: 120000; concentration of n-butyl lithium is 1mol / L; [THF] / [active center] = 2

[0036] Note: Styrene and isoprene are polymer grade; THF is the activator, which requires analytical purity. Calculation: The triblock monomer weight ratio is as follows:

[0037] Styrene:isoprene:styrene=7.5:85:7.5

[0038] The amount of styrene in the first section: m×7.5%=m 1 ;Molecular weight: 120000×7.5%=M 1 .

[0039] The amount of isoprene in the second stage: m×85%=m 2 ;Molecular weight: 120000×85%=M 2 .

[0040] The amount of styrene in the third stage: m×7.5%=m 3 ;Molecular weight: 120000×7.5%=M 3 .

[0041] active center = m 1 / M 1 =m 2 / M 2 =m 3 / M 3 = a mol

[0042] Then the added volume of n-butyllithium is: V=a mol / l (mol / L)=a L

[0043] Organic solvent: cyclohexane, analytically pure.

[0044] Spe...

Embodiment 2

[0054] To prepare a transdermal patch adhesive:

[0055] The SIS used to synthesize the adhesive in the present invention is the SIS claimed in this patent, and its content ranges from 1% to 55% of the adhesive system;

[0056] Softener, plasticizer: one or more of naphthenic oil, hydrogenated naphthenic oil, liquid paraffin, castor oil, hydrogenated castor oil, epoxy soybean oil, the content range is 30%-60% of the adhesive system %;

[0057] Tackifier: including C 5 Petroleum resin and its hydride, C 9 Petroleum resin and its hydride, C 5 -C 9 One or more of petroleum resin and its hydrogenated products, hydrogenated rosin resin, rosin resin, and other rosin derivatives, the content of which ranges from 10% to 60% of the adhesive system;

[0058] Antioxidant: include one or both of antioxidant 1010 (trade name) and antioxidant 264 (trade name), the content range of which is 0.1%-5% of the adhesive system.

[0059] Additives with special functions: such as ingredients t...

Embodiment 3

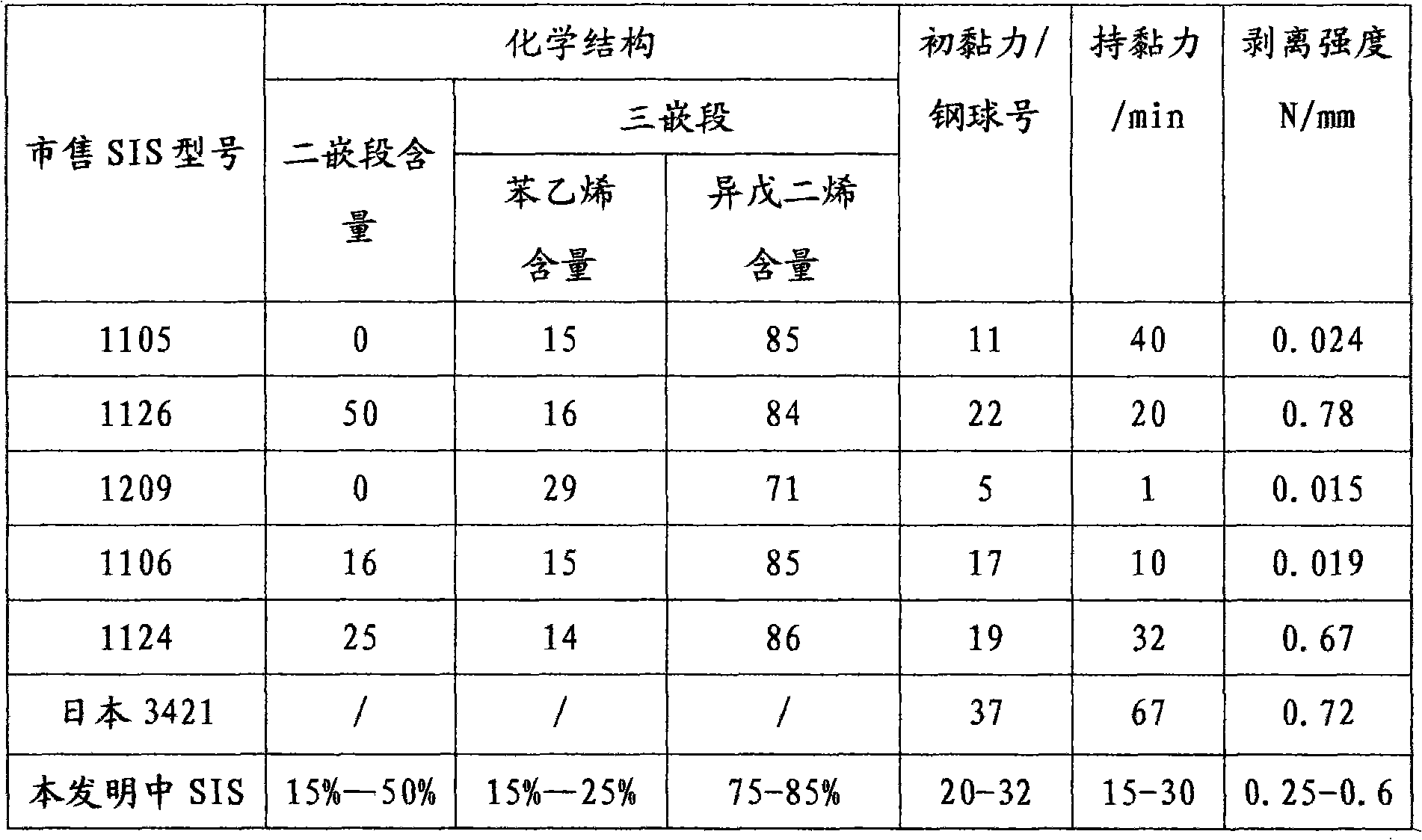

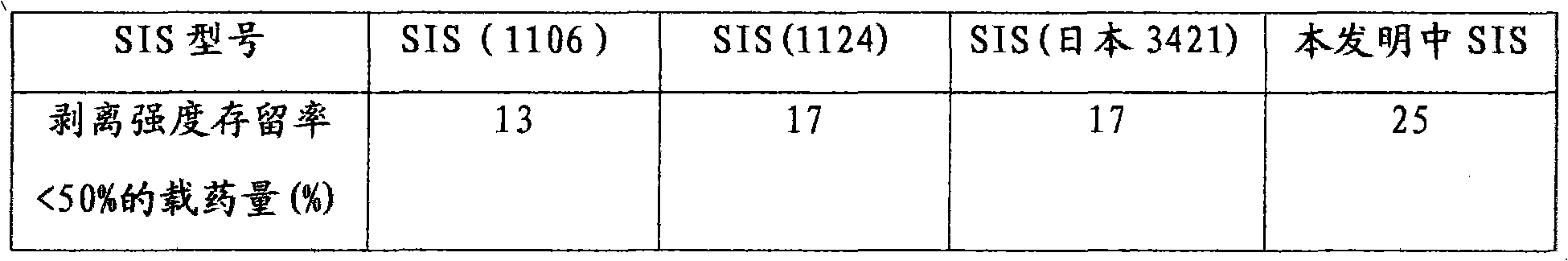

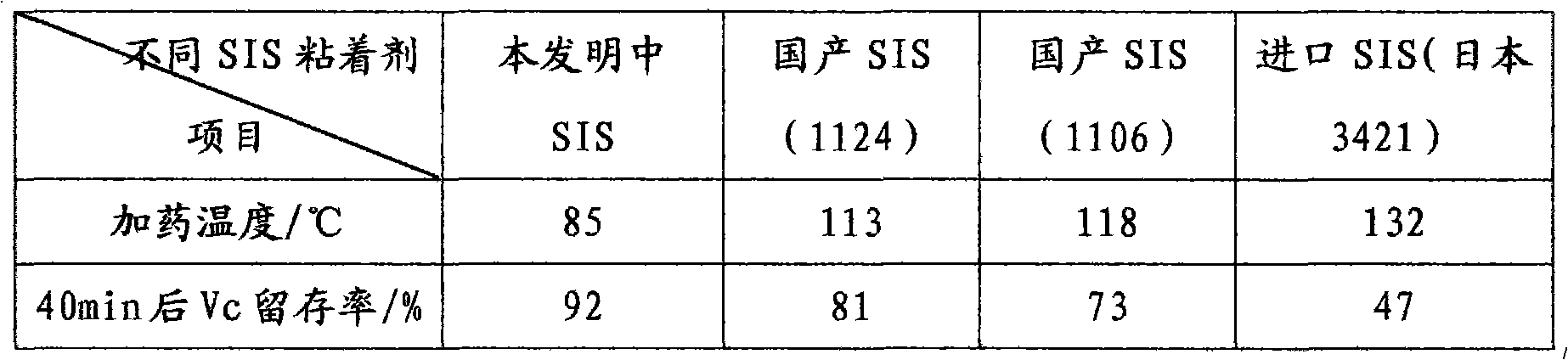

[0065] Biomechanical studies of different structures:

[0066] At present, it is difficult to prepare an ideal transdermal absorption patch with commercially available SIS, because the initial adhesion, holding force, and peeling force (three forces) of the transdermal patch not only affect the adhesive performance of the patch, but also directly Affect the compliance of people's medication, through a large number of human body application tests, the present invention has explored the best mechanical properties of the transdermal patch suitable for human skin as (tested by the Pharmacopoeia method of the People's Republic of China):

[0067] Initial viscosity / ball number

Holding force / min

Peel strength / (N / mm)

[0068] 16-35

8-30

0.02-0.6

[0069] At present, it is difficult for commercially available SIS models to prepare adhesives to meet the above requirements. Or the initial adhesion is too small, it is not easy to bond t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com