Conjugated polymer material of fluorene and perylene and preparation method thereof

A conjugated polymer, polymer technology, applied in chemical instruments and methods, luminescent materials, use of gas discharge lamps, etc., to achieve the effects of improving injection and transmission capacity, simple synthesis process, and improving device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the synthesis of polymer structure I 1 (m=1, wherein alkyl is n-octyl)

[0051] Poly[(9,9-di-n-octylfluorene-2,7-diyl)-alt-co-(perylene-1,6(8)-diyl)] (PDOFPE). 2,7-dibromo-9,9-dioctylfluorene (M1) (5.4844g, 1.0mmol), 3,10-dibromoperylene borate (PRB) (0.4201g, 1.0mmol) placed in pre- In a 100mL flask with a stirring bar, vacuumize and pass nitrogen three times, inject oxygen-free toluene (20mL) into the flask with a syringe. The mixture was heated to 80°C and stirred until the monomers were completely dissolved, and tetrakis(triphenylphosphide)palladium (Pd(PPh 3 ) 4 ) (0.01 mmol) in toluene (10 mL), and inject anaerobic nitrogen-saturated 2M sodium carbonate solution (5 mL) with a syringe. Then the system was heated to 90°C, and after 48 hours of reaction, phenylboronic acid (1.2g, 0.1mmol) was added to react for 12h to seal off the bromine end of the copolymer, and then bromobenzene (1mL, 1.5g, 10mmol) was added to react for 12h to seal off the copoly...

Embodiment 2

[0056] Example 2: Absorption spectra of solutions and films of the polymer PDOFPE (product of Example 1), photoluminescence spectroscopic determination.

[0057] Dissolve PDOFPE in tetrahydrofuran solution, and use Shimadzu UV-3150 ultraviolet-visible spectrometer and RF-530XPC fluorescence spectrometer to measure the absorption and emission spectra. The photoluminescence spectrum is excited by the maximum absorption wavelength of ultraviolet absorption. The solid film is formed by dropping the solution on a transparent glass plate after the solvent evaporates. The fluorescence quantum efficiency of the solution is measured by 10 in cyclohexane -6 The 9,10-dibenzanthracene solution of M (with a quantum efficiency of 0.9) was measured as a standard, and the measured value was 76%.

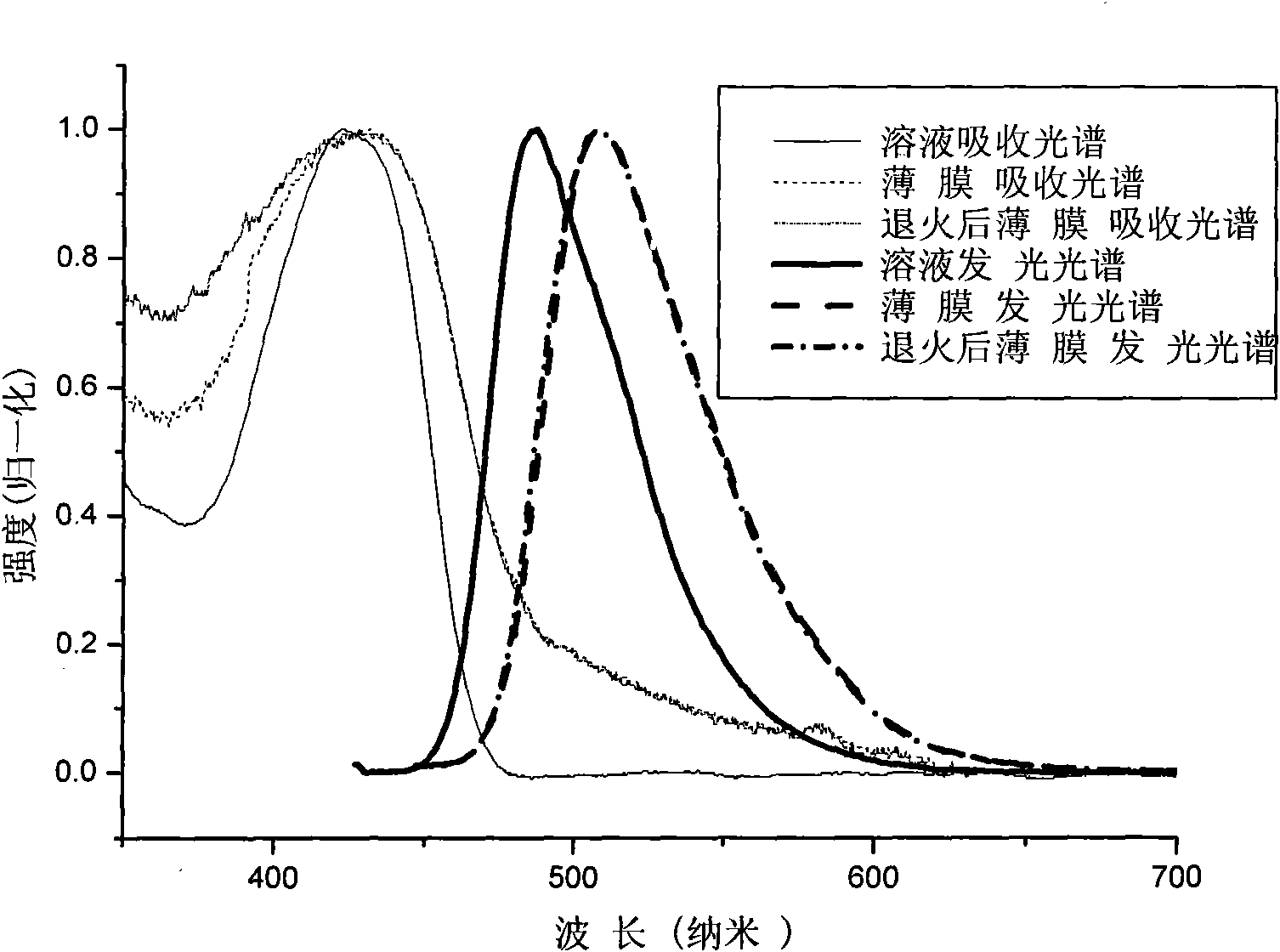

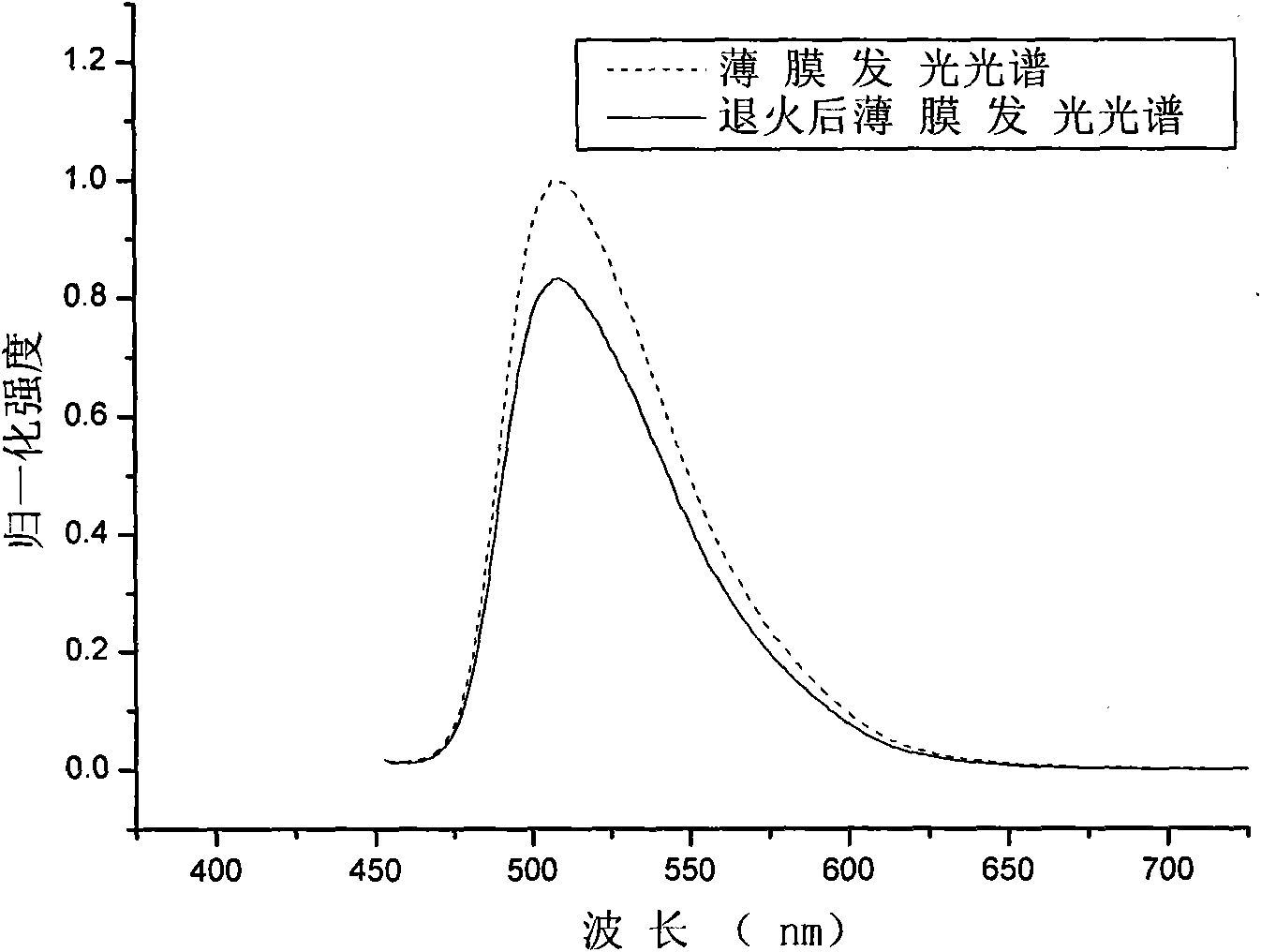

[0058] In the wavelength range greater than 300nm, the PDOFPE solution has a maximum absorption peak of 423nm, the absorption peak is relatively smooth, and the maximum emission of the photolumine...

Embodiment 3

[0060] Example 3: Synthesis of polymer structure II 1 (m=1, where R 3 and R 4 Same, both are 2-ethylhexyloxy)

[0061] Poly[(9,9-bis((4-(2-ethylhexyloxy)phenyl)-fluorene-2,7-diyl)-alt-co-(flower-3,10-diyl)] (PDAOPF-PE). 2,7-dibromo-9,9-bis(4-(2-ethylhexyloxy)phenyl)fluorene (DPM1) (0.733g, 1.0mmol), 3,10-di Bromoperylene borate (PRB) (0.4201g, 1.0mmol) was placed in a 100mL flask with a stirring bar in advance, vacuumed, and nitrogen gas was passed three times, and oxygen-free toluene (20mL) was injected into the flask with a syringe. The mixture was heated After stirring at 80°C until the monomer is completely dissolved, add tetrakis(triphenylphosphide)palladium (Pd(PPh 3 ) 4 ) (0.01 mmol) in toluene (10 mL), and inject anaerobic nitrogen-saturated 2M sodium carbonate solution (5 mL) with a syringe. Then the system was heated to 90°C, and after 48 hours of reaction, phenylboronic acid (1.2g, 0.1mmol) was added to react for 12h to seal off the bromine end of the copolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com